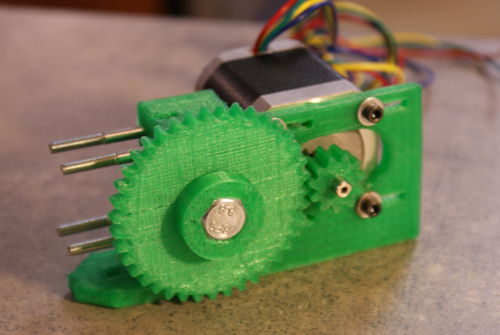

Wade's Geared Extruder

Release status: Stable

Characteristics/advantages of this extruder:

- extrude/print at high speed;

- good for use with a low torque Nema 17 motor;

- no need to glue the PTFE barrel;

- no need to use expensive metal gears;

- no need to use expensive and complex tools - just one hand drill, a file and a M3 tap;

- no need to make splines on motor shaft;

- no need to do two precision flats on motor shaft;

Photos from Thingiverse , of other people's copies of this extruder.

Here is a link to a previous version of this page that describes an earlier version of this extruder that uses an M4 shaft, and includes more details about pull testing the two versions: "Geard Nema 17 Exteruder Version 0.5"

Mechanical Construction

Material

- 3 X 608 bearings (Skateboard bearings);

- 1 X M8X50 bolt;

- 1 X M8 nut (Nylock works better, but a pair of nuts will also work);

- 4 X M8 washers;

- 1 X M8X20 piece of smooth bar, threaded bar or a bolt;

- 4 X M4X45 bolts;

- 4 X M4 nuts;

- 4 X M4 washers;

- 4 X M3X15 bolts;

- 2 X M3X35 bolts;

- 8 X M3 washers;

- 4 X Springs - 1 mm diameter wire, wound to an OD of 10 mm, with 4 active coils. For a given filament drive force, you'll need about twice the spring force - ie, if you want 100 N of filament drive, your springs need to push with about 50 N each.

Printed Parts

- 1 X M8_Extruder_Block_3.stl

- 1 X M8_Extruder_Idler_Block_2.stl

- 1 X 11t17p.stl

- 1 X 39t17p.stl

Motor

- 1 X Nema17 high torque (5 kg*cm is nice) Kysan 2BYGH4803 works well

How to build it

I used a hand drill and a file to cut the slot, then hobbed it with an M3 tap mounted in the drill, using bearings mounted in a vise to let the bolt spin - see the next videos from Casainho:

So far so good!

Here's the test jig:

This extruder hit 16 kg - here's the results: M8 shoulder bolt - 7.0kg, adjusted tension, new springs - 11.0 kg,

Tightened springs, 3 trials:

15.5 kg, 16.5 kg, 15.25 kg

The final failure mode was the stepper running in reverse, as opposed to the filament slipping. That's quite promising.

3D CAD Files

Here's the design files for the latest version:

- extruder body and idler block: File:M8 Extruder 3.zip

- 11 tooth drive gear and 39 tooth M8 hub driven gear: File:M8 Gears.zip

- alternative 11 tooth gear that should be better: File:Nophead gear with setscrew for wade extruder.zip

- (if you do not want to use a vise to support the M8 bolt) use this support for bearings, needed when using M3 tap: File:Pinchwheelwormdrilljig.zip

- You can also get the files from thingiverse although they may not be the most recent.

Finally, here's a spreadsheet to help calculate the proper feedrates: media:feedrates.ods | media:feedrates.xls