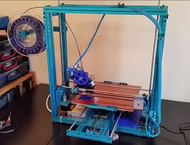

BAM

Release status: working

| Description | BAM is a derivative of the Mendel90 but with clear inspiration from Lulzbot TAZ

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

After having had two kit-printers for many years (Ultimaker & Printrbot) I wanted to solve certain issues I had with these. I wanted larger build volume and more options when it comes to materials, so the design uses an all metal hotend with a directly driven extruder. While my design is based on the Open Source aluminium extrusions from Makeblock, this design can be built with any kind of extrusions. The Makeblock extrusions in the frame are 24x24mm but 20x20mm & 15x15 extrusions should also work fine.

For now this is a placeholder page, but I'll add more pictures as well as building instructions soon.

Resources

Github repository for BAM fork of Marlin https://github.com/jenschr/Marlin

PID settings for the Hexagon hotend

Wades extruder & mounts https://www.youmagine.com/designs/makeblock-wade-extruder

BulldogXL extruder & mounts https://www.youmagine.com/designs/bulldogxl-hexagon-mount

Direct Pinch Extruder https://www.youmagine.com/designs/makeblock-compatible-extruder

Baseplates https://www.youmagine.com/designs/bam-baseplates

Noise dampening feet to print with NinjaFlex (or similar soft plastic) https://www.youmagine.com/designs/makeblock-soft-foot

Links to more information

Build log, http://forum.makeblock.cc/t/3d-printer-build-log/537/

Advantages of this 3D printer compared to other printers http://flashgamer.com/arduino/comments/project-makeblock-3d-printer

Custom controller with OLED screen for Marlin: http://flashgamer.com/blog/comments/making-a-custom-reprap-controller

More pictures from the build: http://maketronics.tumblr.com/tagged/bam

Bill of Materials

This is the complete list of required parts to build this printer (Bill of Materials/BOM):

| Makeblock part name | # of parts used | USD per part | USD total | Where is the part used on the printer? |

|---|---|---|---|---|

| Beam2424-512 | 10 | 12.99 | 129.90 | Main structure |

| Beam2424-312 | 2 | 9.99 | 19.98 | Supports the Y axis assembly and lifts it a bit |

| Beam0824-192 (4-pack) | 6 | 5.25 | 31.49 | At the ends of the Y-axis, 4 as the main frame supporting the build platform |

| Beam0824-144 (4-Pack) | 6 | 4.25 | 25.50 | 5 as spacers in the main structure and one for the filament spool holder. This is the part attached to the main frame |

| Beam0824-112 (4-Pack) | 2 | 3.75 | 7.50 | Filament spool holder. These parts extend the holder to make it more sturdy |

| Beam0824-096 (4-Pack) | 4 | 3.25 | 12.99 | 4 as spacers above electronics |

| Beam0824-048 (4-Pack) | 1 | 2.00 | 2.00 | 1 used below the 192-beam for the Y-axis limit switch |

| Beam0824-032 (4-pack) | 2 | 1.75 | 3.50 | As spacers attaching the Y-axis to the main frame |

| Beam0824-016 (4-Pack) | 1 | 1.00 | 1.00 | 1 tiny spacer to extend the 192-beam so the Y-axis limit switch fits |

| Hardware Pack (bunch of screws) | 1 | 24.99 | 24.99 | Lots of screws required. Haven't counted them all yet |

| Linear Motion Shaft D8x496mm | 8 | 13.99 | 111.92 | 4 for Z-axis, 2 for Y-axis, 2 for X-axis (these two are cut to 440 mm each) |

| Linear Motion Slide Unit 8mm (Pair) | 11 | 6.50 | 71.45 | 4 for Z-axis, 3 for the carriage on the X-axis, 4 for the build platform on the Y-axis |

| 42BYG Stepper Motor Bracket | 4 | 8.99 | 35.96 | 2 for Z-axis, 1 for Y-axis (under platform), 1 for X-axis |

| 42BYG Stepper Motor | 5 | 19.99 | 99.95 | I have used 17hs8401 steppers (57N/cm) on all axes with 5mm shafts for extra torque, but price should be similar |

| Me Micro Switch | 3 | 2.99 | 8.97 | One homing-switch (minimum position) on XYZ axis |

| Nylon Pulley with bearing (4-Pack) | 2 | 3.25 | 6.50 | Used on the stepper bracket for the Y-axis. These must be perfectly centered to avoid print-errors! |

| Bracket P3 (Pair) | 2 | 1.995 | 3.99 | Holds rods for X-axis |

| Bracket 3x3 (4-Pack) | 8 | 1.75 | 13.98 | 4 at the bottom of Z-axis rods, 1 holding the limit switch for the X-axis, 1 holding the print-fan, 2 on X-axis belt |

| Bracket U1 (Pair) | 4 | 2.00 | 7.98 | At each end of the X-axis, plus one at the end of the Y-axis, One holding tube that feeds plastic from spool |

| Bracket L1 (Pair) | 4 | 1.25 | 4.98 | Holds the top of the Linear Motion Shafts on the Z-axis |

| Belt Connector (Pair) | 4 | 1.50 | 5.98 | Two holds wiring from X-axis in place, one holds the belt, one holds the end at the Y-axis switch |

| Plate 3x6 (4-Pack) | 18 | 1.25 | 22.46 | 4 fixes X-axis to main frame, 14 provides spacing at the Z/X-axis bracket, remaining hold bottom plates in place |

| Plate 7x9 (Pair) | 11 | 2.00 | 21.95 | 4 for the corners of the build platform, 6 for the Z/X-axis bracket, 1 holding the Y-axis motor |

| Plate I1 (Pair) | 2 | 2.49 | 4.98 | Fixes Y-axis stepper to the main axis beams |

| Makeblock parts | 122 | 670.61 | ||

| E3d hotend | 1 | 75.00 | 75.00 | v6 HotEnd Full Kit - 3.00mm Direct (GBP 43) |

| 5:8mm coupling | 2 | 5 | 10.00 | Couples the Z-axis stepper/screw |

| 470mm threaded rod, 8mm thick | 2 | 3.50 | 7.00 | Z-axis threaded rod |

| 35mm long 8mm nut | 2 | 1.00 | 2.00 | Couples X-axis to Z-axis |

| 50mm fan with cover | 1 | 9.00 | 9.00 | Electronics fan. Very much required since the motors will pull 1.8A |

| 50mm blower fan (K1BO) | 1 | 5.00 | 5.00 | Printing fan. Directs a steady stream of air to cool the print when required |

| Megatronics, stepsticks | 1 | 165.00 | 165.00 | Main electronics based on Megatronics 2.0, 5 x Polulu DRV8825 |

| 12V/400W power supply | 1 | 42.00 | 42.00 | Powers it all |

| Custom heatbed element 300x300mm, 12V | 1 | 50.00 | 50.00 | Allows for ABS printing |

| Custom alu plate 300x300x4mm | 1 | 30.00 | 30.00 | Distributes heat from the heating element |

| Blue 10 mm expandable, flat braided sleeving | 5 | 0.70 | 3.50 | Found on Ebay. Used for cable management. |

| MK8 extruder gear & 606Z bearing | 1 | 12.00 | 12.00 | Found on Ebay |

| Electronics & 3DP parts | 19 | 410.50 | ||

| 3D printed extruder parts | 1 | 5.00 | 5.00 | Estimate. Could be CNC'd from aluminium to look perfect :) |

| 3D printed extruder bracket (11x7) | 1 | 5.00 | 5.00 | Estimate. Could be an aluminium 11x7 plate with a 6mm drill hole + two cuts to resemble plastic version |

| Springs, 7mm inner, 9mm outer, 22mm height | 4 | 1.50 | 6.00 | Springs for bed leveling. Found at http://stores.ebay.co.uk/We-Do-3D-Printing |

| Printed & various other parts | 6 | 16.00 | ||

| Total | 147.00 | 1097.11 |