CRAMPS2.1

Release status: Experimental

| Description | Cape-RAMPS for BeagleBone

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | KiCAD

|

| External Link |

Contents

- 1 Summary

- 2 Safety

- 3 Known Issues

- 4 ECOs

- 5 Assembly

- 5.1 Required Tools

- 5.2 General Overview

- 5.3 Surface Mount Parts

- 5.3.1 100n 16V 0603 Capacitor

- 5.3.2 10u 6.3V 0603 Capacitor

- 5.3.3 220R 0603 Resistor

- 5.3.4 330R 0603 Resistor

- 5.3.5 2K0 1% 0603 Resistor

- 5.3.6 2K7 0603 Resistor

- 5.3.7 4k7 0603 Resistor

- 5.3.8 10k 0603 Resistor

- 5.3.9 100k 0603 Resistor

- 5.3.10 LED Polarity

- 5.3.11 Yellow 0603 LED

- 5.3.12 Green 0603 LED

- 5.3.13 Red 0603 LED

- 5.3.14 2N7002K FET

- 5.3.15 DMN2075U FET

- 5.3.16 74CBTD3861

- 5.3.17 74ACT244

- 5.3.18 24C256

- 5.3.19 SS14 40V 1A Schottky Diode

- 5.3.20 100u 35V Electrolytic Capacitor

- 5.3.21 Miller Capacitors

- 5.4 Through Hole Parts

- 5.4.1 Pushbutton

- 5.4.2 HEADER_2

- 5.4.3 HEADER_2X2

- 5.4.4 HEADER_3X2

- 5.4.5 HEADER_4X2

- 5.4.6 HEADER_6

- 5.4.7 HEADER_6X2

- 5.4.8 POLOLU_SOCKET

- 5.4.9 KK-2.54-2W

- 5.4.10 KK-2.54-4W

- 5.4.11 Screw Terminals

- 5.4.12 3.5mm Screw Terminal (PT 1,5-2-3,5-H & PT 1,5-3-3,5-H)

- 5.4.13 5.0mm Screw Terminal (PT_2,5-2-5,0-H)

- 5.4.14 FUSE-HOLDER

- 5.4.15 IRLB8743PBF FET

- 5.4.16 BB_EXP_CONN

- 5.4.17 SOCKET_6_LONG

- 5.5 Socketed Parts

- 6 Setup and Testing

Summary

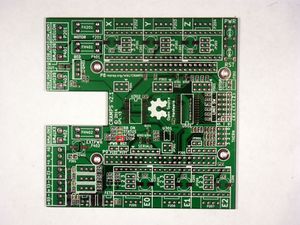

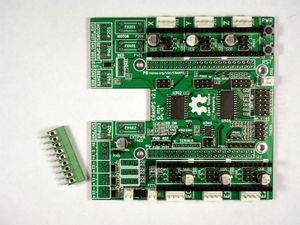

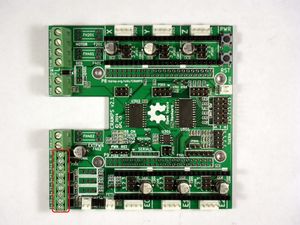

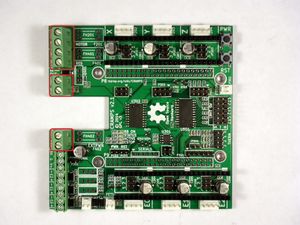

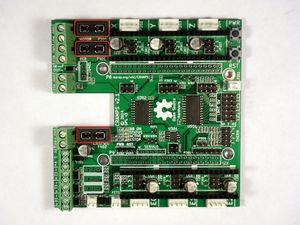

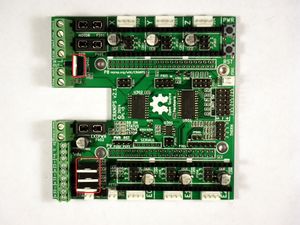

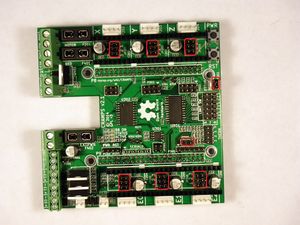

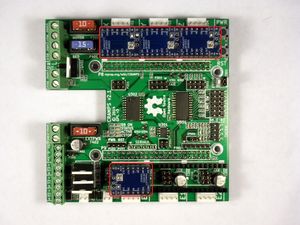

Version 2.1 of the CRAMPS board is a mixed surface-mount and through-hole design. The fine-pitch SMT parts from version 1.0 have been removed, so all parts are now large pitch or through-hole, and are relatively easy to hand solder.

For futher documentation, see: CRAMPS

Safety

The CRAMPS board is designed to handle power levels capable of causing a fire. Be very careful with the initial board checkout, ideally using a power supply protected from short circuit and overload. Never operate your board unattended, and make sure all connected parts subject to heating (including the wires and connectors!) are far away from any potentially combustible material. Always use the proper fuses, and insure your smoke detector is working properly.

Known Issues

- Serial header (P101) does not align with the BeagleBone Black serial header (J1), so it is cumbersome to attach a serial port connection with the cape in place.

- The ESTOP LED operation is "backwards": on when it should be off, and off when it should be on.

ECOs

- Do not populate the 6-pin serial header P101

Assembly

Required Tools

- You must have

- Soldering iron, solder, good tweezers

- You really need

- Solder wick, solder sucker, flux pen

- Optional methods use

- Solder paste, hot plate or oven

General Overview

Soldering the CRAMPS board includes both surface mount and through hole soldering.

The surface mount can be done a few ways. To hand solder, start by putting a small amount of solder on one pad. If you have flux, coat the soldered pad. Use the tweezers to hold the component down in position and heat the solder to tack the component into place (make sure the entire solder blob flows so you don't get a cold solder joint). Then solder the other pads. Also popular is using solder paste for pad by pad soldering, Oven Reflow (need link), and HotplateReflowTechnique

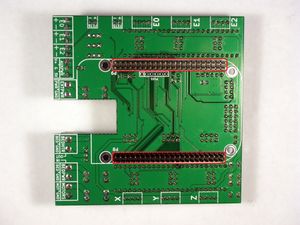

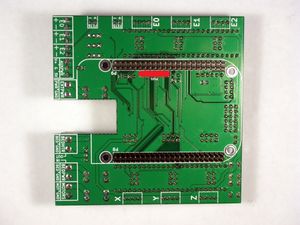

Solder the SMT components first, working through the parts from shortest to tallest. Then solder the through-hole parts on top of the board. Finally solder the parts on the bottom of the board.

Surface Mount Parts

100n 16V 0603 Capacitor

- C301 C302 C501 C502 C503 C504 C505

- These can be placed in any orientation.

10u 6.3V 0603 Capacitor

- C506 C507 C508 C509

- These can be placed in any orientation.

220R 0603 Resistor

- R305 R401 R403 R405 R407 R409 R411

- These can be placed in any orientation.

330R 0603 Resistor

- R101 R102 R303

- These can be placed in any orientation.

2K0 1% 0603 Resistor

- R511 R512 R513 R514

- These can be placed in any orientation.

2K7 0603 Resistor

- R302 R402 R404 R406 R408 R410 R412

- These can be placed in any orientation.

4k7 0603 Resistor

- R304 R306 R307 R314 R515 R516 R517 R518

- These can be placed in any orientation.

10k 0603 Resistor

- R301 R308 R309 R310 R311 R312 R313 R315 R316 R501 R502 R503 R504 R505 R506 R507 R508 R509 R510

- These can be placed in any orientation.

100k 0603 Resistor

- R201 R202 R203 R204 R205 R206

- These can be placed in any orientation.

LED Polarity

The LEDs are marked with a small polarity dot (see image) that should be aligned with the thick line on the silkscreen outline. All three LED colors have identical markings.

Yellow 0603 LED

- LD101 LD401 LD402 LD403 LD404 LD405 LD406

- Place with the cathode terminal (marked with a small dot) closest to the thick line on the silkscreen.

Green 0603 LED

- LD102 LD301

- Place with the cathode terminal (marked with a small dot) closest to the thick line on the silkscreen.

Red 0603 LED

- LD302

- Place with the cathode terminal (marked with a small dot) closest to the thick line on the silkscreen.

2N7002K FET

- Q101 Q301 Q302 Q303 Q304

- Place aligned with the 3 pad SOT-23 footprint.

DMN2075U FET

- Q404 Q406

- Place aligned with the 3 pad SOT-23 footprint.

74CBTD3861

- U501

- Align pin 1 with the silk-screen notch and dot on the PCB.

74ACT244

- U302

- Align pin 1 with the silk-screen notch and dot on the PCB.

24C256

- U301

- Align pin 1 with the silk-screen notch and dot on the PCB.

SS14 40V 1A Schottky Diode

- D401 D402 D403 D404 D405 D406

- Align cathode mark with silk-screen notches on the PCB.

100u 35V Electrolytic Capacitor

- C201 C202 C203 C204 C205 C206 C401

- Align body notches with silk-screen outline on the PCB.

Miller Capacitors

- C402 C403 C404 C405 C406 C407

- These parts are optional and are are not populated by default. They are listed here so you will not worry that some SMT pads do not contain components.

- In the future, parts may be populated to slow down the FET turn on/off times if necessary to avoid dI/dt issues when using alternate FETs.

Through Hole Parts

Pushbutton

- SW101 SW102

- These can be placed in any orientation.

HEADER_2

- JP501 P102 P103 P301

- These can be placed in any orientation.

HEADER_2X2

- JP301

- These can be placed in any orientation.

HEADER_3X2

- JP201 JP202 JP203 JP204 JP205 JP206 P304

- These can be placed in any orientation.

HEADER_4X2

- P303 P503 P504

- These can be placed in any orientation.

HEADER_6

- P305 P501

- These can be placed in any orientation.

HEADER_6X2

- P502

- These can be placed in any orientation.

POLOLU_SOCKET

- P208 P209 P210 P211

- These can be placed in any orientation.

KK-2.54-2W

- P302 P407 P409

- Place with friction lock away from the board edge. Alternately, standard pin headers or other connectors (2.54mm screw terminals, etc) can be used in place of the KK series headers shown.

KK-2.54-4W

- P202 P203 P204 P205 P206 P207

- Place with friction lock away from the board edge. Alternately, standard pin headers or other connectors (2.54mm screw terminals, etc) can be used in place of the KK series headers shown.

Screw Terminals

Adjacent terminal blocks must be connected to form a single large block prior to soldering onto the board.

3.5mm Screw Terminal (PT 1,5-2-3,5-H & PT 1,5-3-3,5-H)

- P405 P406 P408

- P404

- Place so the opening for the wire faces the board edge. You may also choose other connectors with the same mounting pitch.

5.0mm Screw Terminal (PT_2,5-2-5,0-H)

- P201 P401 P402 P403

- Place so the opening for the wire faces the board edge. You may also choose other connectors with the same mounting pitch.

FUSE-HOLDER

- FH201 FH401 FH402

- These can be placed in any orientation.

IRLB8743PBF FET

- Q401 Q402 Q403 Q405

- These must be orientated as in the picture. The tall heat sink tab of the MOSFET needs to be aligned with the double-line on the silk-screen.

BB_EXP_CONN

- P8 P9

- These can be placed in any orientation.

SOCKET_6_LONG

- P101

- Do NOT populate the serial header on the V2.1 boards, or you will not be able to plug the cape onto your BeagleBone!

Socketed Parts

SHUNT

- S201 S202 S203 S204 S205 S206 S207 S208 S209 S210 S211 S212 S213 S214 S215 S216 S217 S218 S301 S501

- Adjust the populated shunts as required for your desired micro-step setting.

- If you have a physical ESTOP switch, connect it to the ESTOP header instead of using the shunt.

Fuses

- 10A

- F201 F402

- 15A

- F401

- These can be placed in any orientation.

Pololu

- U201 U202 U203 U204 U205 U206

- These must be placed with pin 1 aligned with the heavy silkscreen rectangle indicating pin 1 on the PCB, and be careful you do not plug the modules in "off by one", or shifted in the socket. There are heavy silkscreen lines on PCB indicating the "break" between modules.

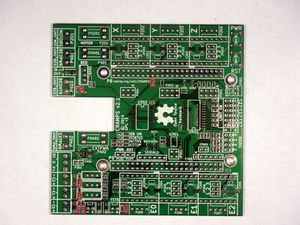

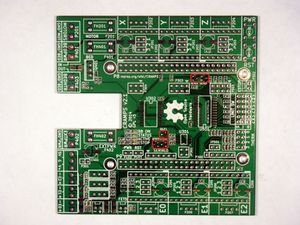

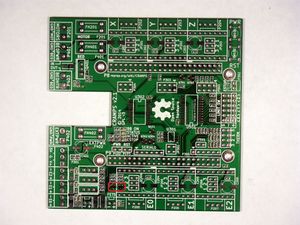

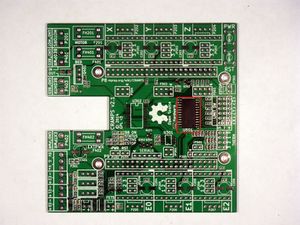

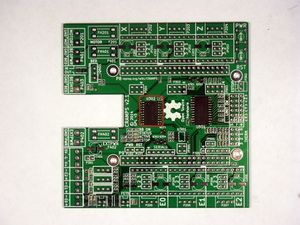

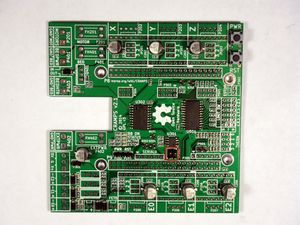

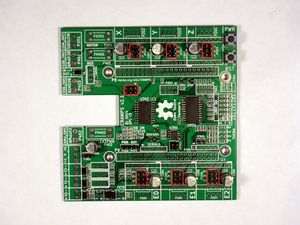

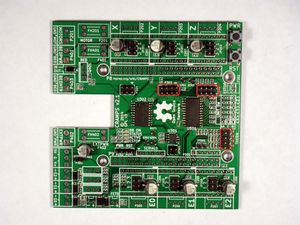

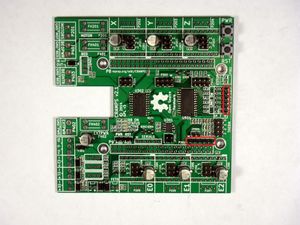

Complete

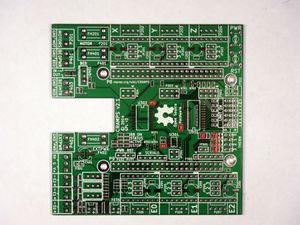

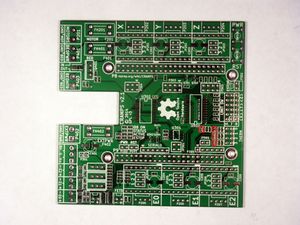

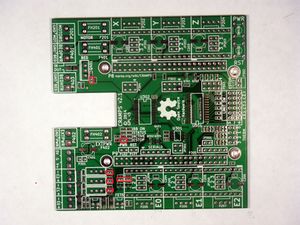

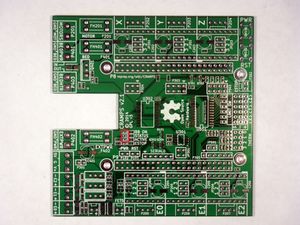

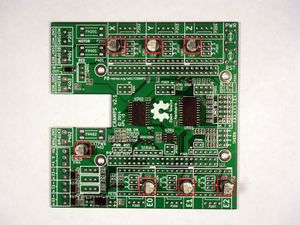

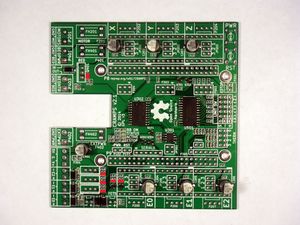

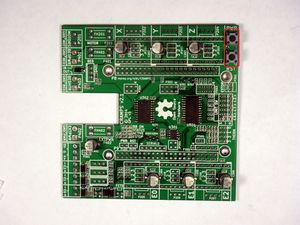

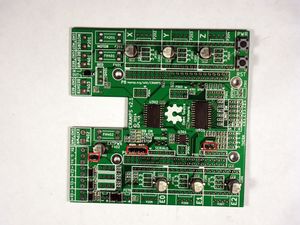

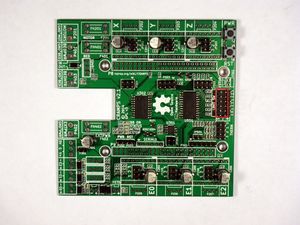

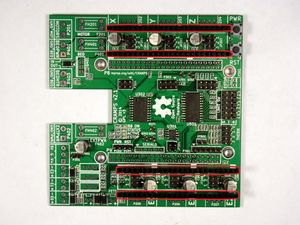

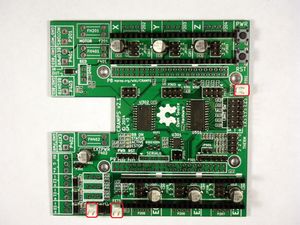

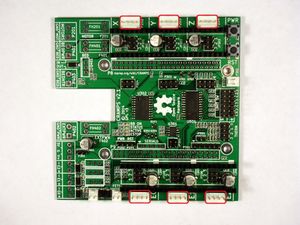

Assembly is now complete, hopefully your board looks something like this one (the Pololu modules are intentionally not shown so the parts underneath them are visible).

Setup and Testing

The EEPROM needs to be programmed with appropriate data, and the various features of the board need to be tested for proper functionality.

Example EEPROM data is located in github along with the PCB design files, but currently no programming or production test code is available. An unprogrammed EEPROM simply means you need to load the cape overlay manually, which is already done by the example configurations available with Machinekit.

Stay tuned.