Fabricating Ordered 2-D Nano-Structured Arrays Using Nanosphere Lithography

|

By Michigan Tech's Open Sustainability Technology Lab.

Wanted: Students to make a distributed future with solar-powered open-source RepRap 3-D printing and recyclebot recycling. |

|

Contents

Source

- Chenlong Zhang, Sandra Cvetanovic, Joshua M. Pearce. Fabricating Ordered 2-D Nano-Structured Arrays Using Nanosphere Lithography. MethodsX 4, 2017, pp. 229-242. DOI:10.1016/j.mex. open access

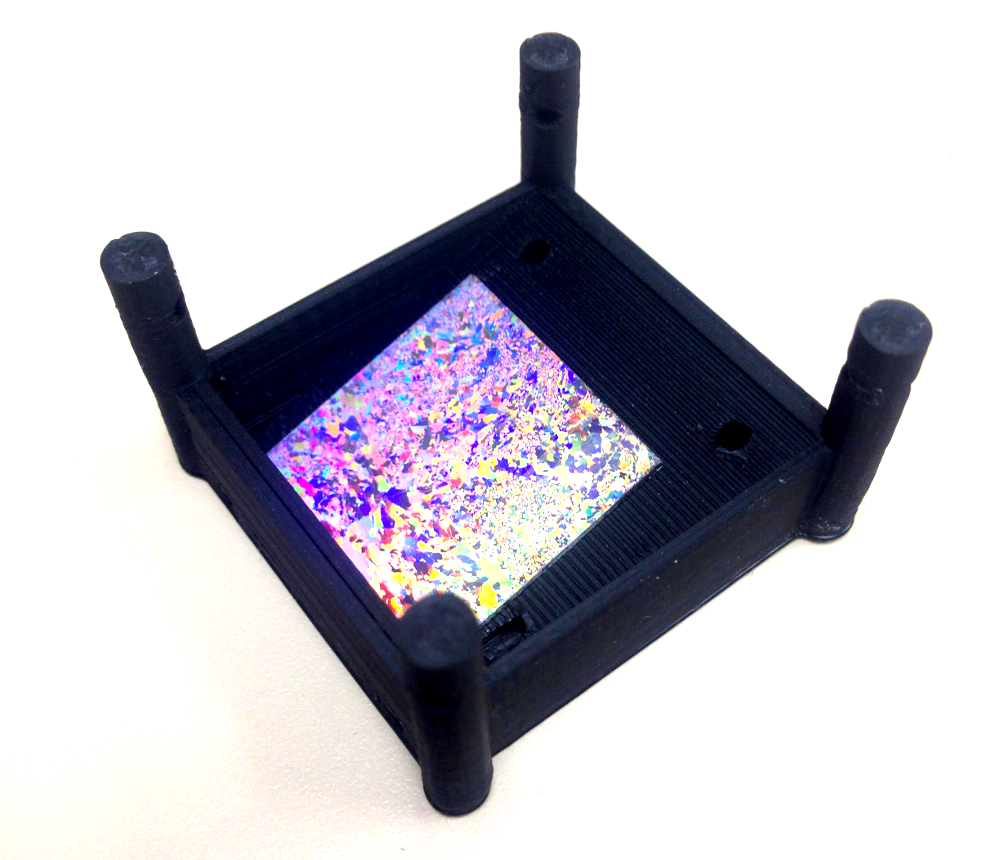

- 3D printed parametric dipper https://www.youmagine.com/designs/dip-holder-for-nanosphere-lithography

Abstract

Recent advances in the use of plasmonic metamaterials to improve absorption of light in thin-film solar photovoltaic devices has created a demand for a scalable method of patterning large areas with metal nanostructures deposited in an ordered array. This article describes two methods of fabricating ordered 2D nanosphere colloidal films: spin coating and interface coating. The two methods are compared and parameter optimization discussed. The study reveals that:

- For smaller nanosphere sizes, spin coating is more favorable, while for larger nanospheres, the angled interface coating provides more coverage and uniformity.

- A surfactant-free approach for interface coating is developed to fabricate zero-contamination colloidal films.

- Each of the methods reaches an overall coverage of more than 90% and can be used for nanosphere lithography to form plasmonic metamaterials.

Keywords

microsphere lithography; plasmonic; nanosphere lithography; dip coating; spin coating; nanosphere; plasmonic; metamaterial; photovoltaic; synthesis

Methods

Detailed methods in the paper - also supported by:

See Also

- Plasmonic enhancement of amorphous silicon solar photovoltaic cells with hexagonal silver arrays made with nanosphere lithography

- A new method of preparing highly conductive ultra-thin indium tin oxide for plasmonic-enhanced thin film solar photovoltaic devices

- Limitations of ultra-thin transparent conducting oxides for integration into plasmonic-enhanced thin-film solar photovoltaic devices

- Influence of Oxygen Concentration on the Performance of Ultra-Thin RF Magnetron Sputter Deposited Indium Tin Oxide Films as a Top Electrode for Photovoltaic Devices

- Advances in plasmonic light trapping in thin-film solar photovoltaic devices

- Controlling optical absorption in metamaterial absorbers for plasmonic solar cells

- Plasmonic Perfect Meta-Absobers for a-Si PV Devices

- Multi-resonant silver nano-disk patterned thin film hydrogenated amorphous silicon solar cells for Staebler-Wronski effect compensation

- Enhancement of hydrogenated amorphous silicon solar cells with front-surface hexagonal plasmonic arrays from nanoscale lithography

- Optimal Design of Thin-film Plasmonic Solar Cells using Differential Evolution Optimization Algorithms

- Scalable honeycomb top contact to increase the light absorption and reduce the series resistance of thin film solar cells