File:Sand the copper.JPG

Size of this preview: 800 × 533 pixels. Other resolutions: 320 × 213 pixels | 3,888 × 2,592 pixels.

Original file (3,888 × 2,592 pixels, file size: 2.67 MB, MIME type: image/jpeg)

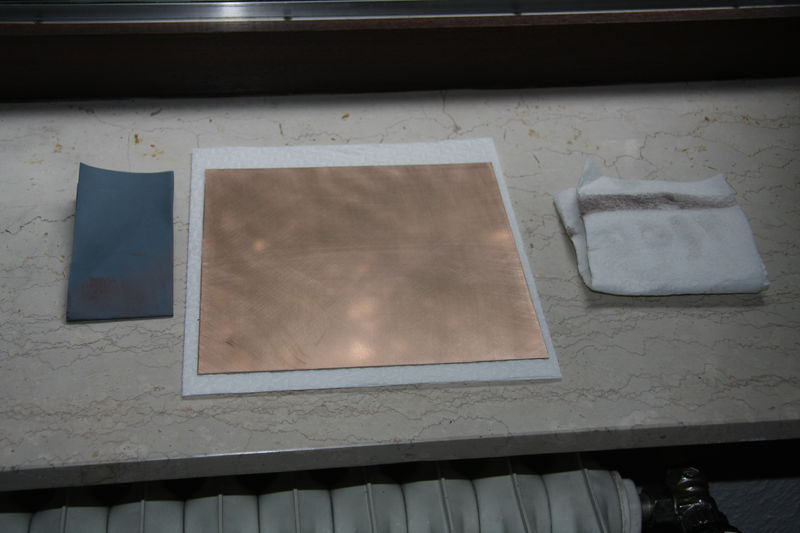

Toner Transfer Method/Building my own Heatbed

The surface needs to be slightly rough for the toner to grip on the copper. But the surface has to be very smooth likewise. So I use a very fine sandpaper (1200 parts per millimeter; 1000 will do as well). After sanding the surface still shines, but has some very small scratches that expand the surface area of the copper. Later, when ironing the layout onto the copper, the toner grips onto the big surface of the sanded copper a bit more, than on the waxed paper of the catalog. Using a very fine sandpaper allows very fine details to be transfered successfully.

File history

Click on a date/time to view the file as it appeared at that time.

| Date/Time | Thumbnail | Dimensions | User | Comment | |

|---|---|---|---|---|---|

| current | 07:03, 30 June 2013 |  | 3,888 × 2,592 (2.67 MB) | RobertKuhlmann (talk | contribs) | The surface needs to be slightly rough for the toner to grip on the copper. But the surface has to be very smooth likewise. So I use a very fine sandpaper (1200 parts per millimeter; 1000 will do as well). After sanding the surface still shines, but has s |

- You cannot overwrite this file.

File usage

The following 2 pages link to this file: