FoldaRap Buyers Guide

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

This project was for myself, as I needed a RepRap that is easy to carry around and for the challenge of making a folding 3d-printer. But I believe in open-source and sharing and all the revolution behind that. Thus I try to well document it, in case others want to make one; to acknowledge all the things we own to those who went before, and to encourage those who come after to do the same.

On a more long-term view, I didn't planned to create a company out of it, I hoped to see it grow on itself in the wild, just by indicating how to source it, because I have more fun in designing stuff than marketing it. And after 500 machines and few other models for the industry, I'm back to that principle :)

"Ideas are like living things and breed happily in an open-source context" as I like to think ^^ (on the same spirit I like this comment from User:Adrianbowyer)

Contents

Bill Of Material (BOM)

2017-10-14 : With the FoldaRap 3.0 I will maintain the inventory in a Libre-Office datasheet. You can find it the github repo (here). I will progressively archive the BOM of the previous version below.

Total end cost for 1 machine : ~400-500€ when you include all taxes and shipping costs. Make group orders with friends if you can.

Hardware

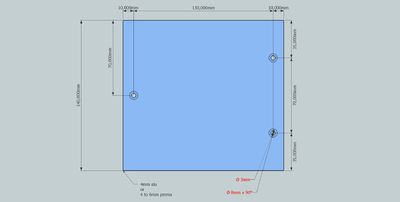

- The bed can also be made of acrylic in case of a non-heated bed.

Electronic

1 standard female cable - EU/C13 - UK RS6266739 / US RS7316163 1m of 18AWG wire (200mm red, 200m black, 150mm green) for the switch/plug/psu - Read also WiresAndConnectors 1 kapton film heater

Laser cut parts

Have them cut at a local FabLab/Makerspace. Or order them from my Ponoko/Sculpteo hub (need to be updated).

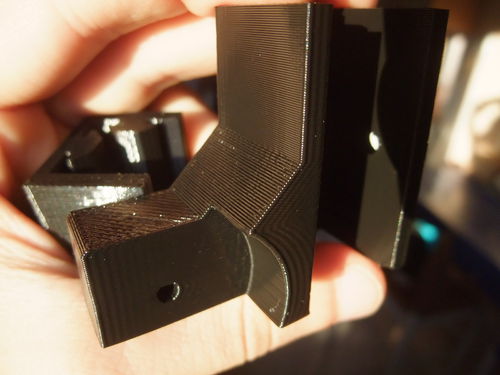

Printed parts

If you can print your own parts it will take ~500gr.

Material : PLA

Because some parts act as sliders on the aluminium profiles. You can print the other parts in what you want.

Recommended settings

- Infill : 25-30%

- Infill pattern : hexagonal

- It is advised to have a well calibrated machine (+/- 0.05mm on measured parts) : http://forums.reprap.org/read.php?282,159683

I recorded this little video where I'm playing with some parts freshly printed, to show what to expect about the tight tolerances.

<videoflash>rRXyc5I8yfo</videoflash>

The part that slide under it's own weight (16gr) have been slided back and forth a few time.