Foton 3Dprinter

Release status: unknown

| Description | Streamlined mechanical system

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Overview

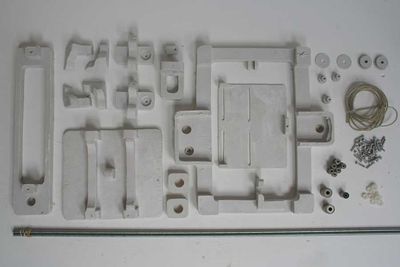

The foton 3D printer's is a redesign of the origional Mendel printer developed by Fotonlabs.

The designs for this printer are based upon trying to developing a 3D printer that is both technically and economically accessible to as broader spectrum of person as possible. This is seen to be achived thought a design that both simplifies the mechanics to reduce technical complexity and by developing a streamline production process to maintain a low cost per unit end product. The primary factors in the designs of this printer have been:

1. Maintaining a low level of technical complexity for the end user

2. Cost efficiency and commercially

3. Esthetics and form

Materials

The mechanics of this printer are made predominately form a polyester resin, which provides a low cost solution for the bulk of the material, with this is added a flexible agent to vary the rigidity or flexibility of the material. Steel(stainless and mild) is used to provide structural strength, both in the fasteners and for the up right of the frame.

Production process

The majority of the parts are made from an open cold casting process, which is both time and cost efficient and opens the printer up to the possibility of mass production, with production time of parts currently down to as low as one hour.

Assembly

Intergrating many of the mechanical parts has led to a large reduction in assembly time and complexity, with assembly time currently bellow five hours. One of the primary aims has been to create a design with as few parts as possible resulting in a quick and easy to assemble printer suited to the no technically minded person.

Electronics

The development of this printer to date has focused on the mechanics which are designed to work with the standard set of electronics used on a Mendel print, being on a 1:1 scale with the standard Mendel in size means that there should be no additional alterations to the software or electronics needed. VIDEO NEED REUPLOAD

Distribution

This design is primarily aimed at an "Ikea style" form of distribution, easy to mass produce parts that can be made into a flat pack for shipping and assembled by the average person. Another possible means of distribution maybe to reduce the plastic parts down to a printable size, thus making the printer capable of producing many of its own parts. A number of developers release have been already been made available via eBay.

Latest developments

The latest developments have focused on:

1. Adding Steel rods to a X and Z axes.

2. Changing bearing system to plastic bearings.

3. Switching back to an all plastic frame.

4. Experimenting with CNC milling(See video).