Fused filament fabrication

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

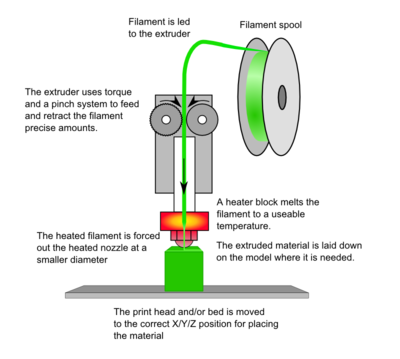

FFF (fused filament fabrication) is an additive manufacturing technology. A fused filament fabrication tool deposits a filament of a material (such as plastic, wax, or metal) on top or alongside the same material, making a joint (by heat or adhesion).

Fused Filament Fabrication is equivalent to Fused Deposition Modeling. However, the term fused deposition modeling and its abbreviation to FDM are trademarked by Stratasys Inc.. The term fused filament fabrication (FFF), was coined by the members of the RepRap project to provide a phrase that would be legally unconstrained in its use.

Objects printed with FFF are layered, so they have a grain like wood. Even when printed with an infill rate of 100%, such objects are not quite as strong (in some directions) as others. Tests show that printing the same object in different orientations, with different infill patterns, can give differences in strength of almost 2 to 1. An interlocking infill pattern seems to give more strength. For more information, see the sources listed in Further Reading.

Materials used with FFF

Most popular are PLA and ABS, but (non-comprehensive) also printable:

Other materials are listed here:

Further reading

- Wikipedia:fused deposition modeling

- Glossary

- "The Rack" - A writeup of experiments on printed ABS material properties

- RepRap forum: "Questions about durability of repraped models"

- "Spot on flow rate" - A discussion of filament flow rate and infill