Mechanical Properties of Components Fabricated with Open-Source 3-D Printers Under Realistic Environmental Conditions

|

By Michigan Tech's Open Sustainability Technology Lab.

Wanted: Students to make a distributed future with solar-powered open-source RepRap 3-D printing and recyclebot recycling. |

|

| This page is part of an international project hosted by MOST to use RepRap 3-D printing to make OSAT for sustainable development. Learn more.

Research: Open source 3-D printing of OSAT • RecycleBot • LCA of home recycling • Green Distributed Recycling • Ethical Filament • LCA of distributed manufacturing • RepRap LCA Energy and CO2 • Solar-powered RepRaps • solar powered recyclebot • Feasibility hub • Mechanical testing • Lessons learned • MOST RepRap Build Make me: Want to build a MOST RepRap? - Start here! • Delta Build Overview:MOST • Athena Build Overview • MOST metal 3-D printer • Humanitarian Crisis Response 3-D Printer |

Source

- B.M. Tymrak, M. Kreiger, J. M. Pearce, Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions, Materials & Design, 58, pp. 242-246 (2014). http://dx.doi.org/10.1016/j.matdes.2014.02.038. open access

Abstract

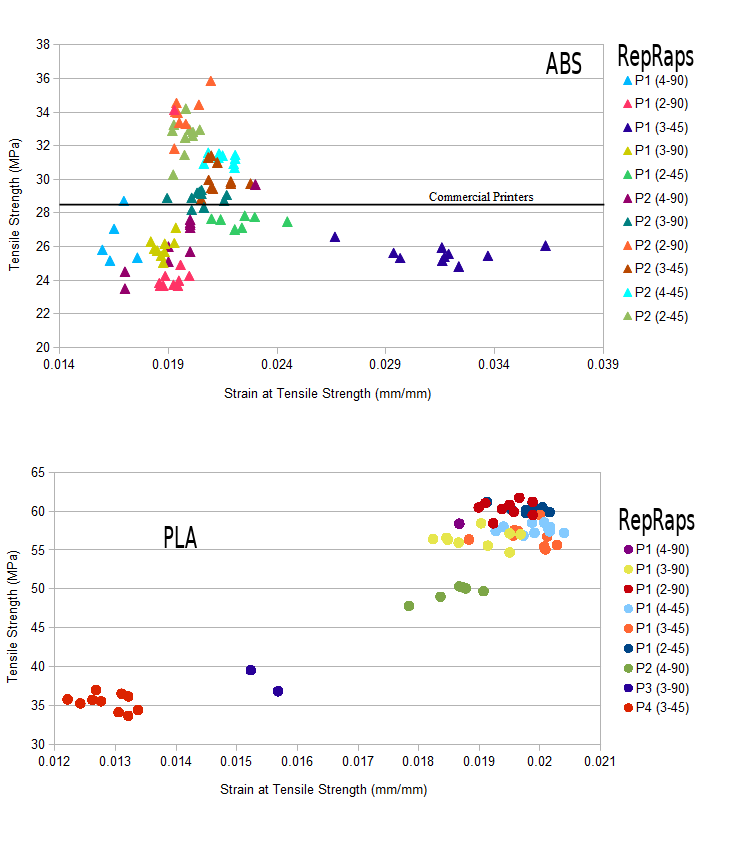

The recent development of the RepRap, an open-source self-replicating rapid prototyper, has made 3-D polymer-based printers readily available to the public at low costs (<$500). The resultant uptake of 3-D printing technology enables for the first time mass-scale distributed digital manufacturing. RepRap variants currently fabricate objects primarily from acrylonitrile butadiene styrene (ABS) and polylactic acid (PLA), which have melting temperatures low enough to use in melt extrusion outside of a dedicated facility, while high enough for prints to retain their shape at average use temperatures. In order for RepRap printed parts to be useful for engineering applications the mechanical properties of printed parts must be known. This study quantifies the basic tensile strength and elastic modulus of printed components using realistic environmental conditions for standard users of a selection of open-source 3-D printers. The results find average tensile strengths of 28.5 MPa for ABS and 56.6 MPa for PLA with average elastic moduli of 1807 MPa for ABS and 3368 MPa for PLA. It is clear from these results that parts printed from tuned, low-cost, open-source RepRap 3-D printers can be considered as mechanically functional in tensile applications as those from commercial vendors.

Highlights

- Open-source self-replicating rapid prototyper, RepRaps are 3-D printers.

- Low costs enable mass-scale distributed digital manufacturing in ABS, PLA.

- Average tensile strengths of 28.5 MPa for ABS and 56.6 MPa for PLA.

- Average elastic moduli of 1807 MPA for ABS and 3368 MPa for PLA.

- RepRaps are as mechanically functional as commercial 3-D printers

Major Findings

Using tensile specimen here:http://www.thingiverse.com/thing:28987

See Also

- Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3-D Printing

- The Effects of PLA Color on Material Properties of 3-D Printed Components

- Open source rapid prototyping of OSAT

- RepRap Mechanical Testing Literature Review

- Tensile_test_protocol:_MOST

- Wood Furniture Waste-Based Recycled 3-D Printing Filament

- Viability of Distributed Manufacturing of Bicycle Components with 3-D Printing: CEN Standardized Polylactic Acid Pedal Testing

- Environmental life cycle analysis of distributed 3-D printing and conventional manufacturing of polymer products

- Recyclebot

- Life cycle analysis of distributed recycling of post-consumer high density polyethylene for 3-D printing filament

- Recyclebot on RepRap wiki

- Mechanical testing of polymer components made with the RepRap 3-D printer

- Development and feasibility of applications for the RepRap 3-D printer

- Life cycle analysis of distributed polymer recycling

- Solar powered distributed customized manufacturing

- MOST RepRap Build

- Life cycle analysis of distributed polymer recycling

- Applications of RepRap distributed production - literature review

- What is the influence of infill %, layer height and infill pattern on my 3D prints?

- A few ways to strengthen 3D printed parts - STEP 3D (really nice summary of methods to strengthen parts)

- [PDF Impact of Process Parameters on Tensile Strength of FDM Printed Crisscross PLA]

- Improving the Impact Strength and Heat Resistance of 3D Printed Models: Structure, Property, and Processing Correlationships during Fused Deposition Modeling (FDM) of Poly(Lactic Acid) - showed increased impact resistance with print bed temp high, more crystalline - post print anneal

Media

- Open-source 3D printed parts often stronger than proprietary versions -3Ders

- Michigan Tech Study Suggests Some RepRap 3D Prints Are As Strong as Commercial 3D Printers- 3D Printing Industry

- Some RepRap 3D Prints Are As Strong As Industrial And Commercial 3D Printers - 3D Printer Plans

- Measuring Open Source Hardware 3D-Printed Material Strength- EE Times

- Desktop 3D Printed Parts Can Be as Tough as Industrial and St3p3D Shows You How - 3D Printing and Industry

- A few ways to strengthen 3D printed parts - St3P3D and 3Ders