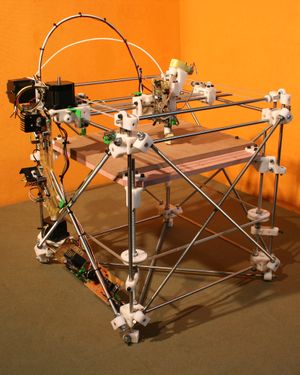

RepRapOneDarwin

Contents

How to build RepRap 1.0 "Darwin"

Overview

RepRap 1.0 "Darwin" is a rapid prototyping machine that is capable of making the majority of its own component parts. Instructions and all necessary data are available completely free under the GNU General Public Licence from this website to everyone.

As RepRap 1.0 "Darwin" can copy itself, once you have one you can make others for your friends; or if they have one you can ask them to make one for you. Of course, you can also make as many as you want for yourself; the more you have, the faster you will be able to make other items. RepRap etiquette asks that you use your machine to make the parts for at least two more Darwins for other people at cost, as well as using it to make whatever you or anyone else on the internet can think up...

Darwin consists of a frame made from rods and printed parts. A flat build platform moves vertically in that frame, driven on screw threads by a stepper motor. At the top of the frame there are two write heads that move horizontally (driven by toothed belts and two more steppers) extruding a thin stream of molten plastic to form new layers on the build base. The machine prints layer by layer to form a solid object. The build base then moves one increment down, the second layer is extruded, and so on. There are two heads to allow a filler material to be laid down as well as the plastic. This filler is used to support overhanging parts of the objects being built, and is removed when the process is finished.

Specification

The RepRap 1.0 "Darwin" machine has the following characteristics:

- Working volume: adjustable, but nominally 230mm (X) x 230mm (Y) x 100mm (Z)

- Working materials: Polycaprolactone and a filler/support

- Configuration: 3-axis Cartesian drive using stepper motors

- Line and space: 0.5mm and about 0.2mm

- Feature size: about 2mm

- Positioning accuracy: 0.1 mm

- Layer thickness: adjustable, but nominally 0.3mm

- Computer interface: USB

- Material handling: Two fixed material deposition extruders, user exchangeable

- Power supply needed: 6A max, 3A continuous at 12V DC

- Driving computer and operating system needed: Microsoft Windows, Linux, Unix, or Mac

- Exterior dimensions: adjustable, but nominally 600 mm wide x 520 mm deep x 650 mm high

- Weight: about 14 Kg

Bill of Materials (BoM)

The Get a RepRap kit page will give you several options on how to get hold of the bits you need. It also links to the individual designs (STL files) of custom parts so you can make your own if you like.

Click here for automatically generated BoMs.

Before ordering parts please check here for notes and variations.

Alternatively, the current parts lists, as well as links to suppliers where available are listed below. If you have any questions on parts, please ask on the forums.

| Module | Extra Output Formats |

| Master Bill of Materials | HTML - PDF - Open Office - Excel - Google Spreadsheet |

| Cartesian Robot | HTML - CSV - Text - PDF - Open Office - Excel - RSS - ATOM |

| ThermoPlast Extruder | HTML - CSV - Text - PDF - Open Office - Excel - RSS - ATOM |

| Universal Controller v1.2 | HTML - CSV - Text - PDF - Open Office - Excel - RSS - ATOM |

| PowerComms v1.2 | HTML - CSV - Text - PDF - Open Office - Excel - RSS - ATOM |

| Opto Endstop v1.0 | HTML - CSV - Text - PDF - Open Office - Excel - RSS - ATOM |

| Stepper Tester v1.0 | HTML - CSV - Text - PDF - Open Office - Excel - RSS - ATOM |

| Darwin Miscellaneous | HTML - CSV - Text - PDF - Open Office - Excel - RSS - ATOM |

What order to do things

The first thing to do is to get the software you will need working. It will run without a RepRap machine attached, and - as you start to build hardware - you can connect it up in a partly-finished state to your computer for testing.

After installing the software, you should start to build the electronics of the RepRap machine. Then you connect them all up (first individually, then together) to your computer and check that everything is talking to everything else.

Then you connect electronics on each of the boards to the motors, heaters, and sensors of the RepRap machine. Once more you can test without the rest of the machine - just plug in the stepper motors, for example, and the software will cause them to rotate on your workbench.

Finally, you build the hardware of the write head and the Cartesian robot that carries it. The order here is not so important, but probably a good way to progress is to make the write head, then make the robot, then finally get those working together.

Software

Requirements

- A fairly modern computer

- Decent graphics card (ATI / NVidia) 64MB+

- Recommended at least 512MB of RAM

- For the older PIC-based RepRap a serial port or USB <-> Serial converter

- Ubuntu/Linux preferred, but OSX and Windows also work.

Files to Download

We offer a few different packages on SourceForge. At some point or another, you will probably need all of them. We keep them as separate packages to make maintenance easier. There are packages for the host software, firmware, electronics, and mechanics.

More info about the files on SourceForge.

Installation

Click here to take you to the instructions for installing the software to drive RepRap on your computer.

Electronics

The electronics are the brains of the system. There are currently 3 generations of electronics that drive a RepRap.

- Generation 1 is the initial system based on Microchip's PIC electronics. Starting with these electronics is not recommended. For people that have the early PIC electronics, here is its documentation. Note that the kits can also be very useful for other projects, since they can operate stand-alone.

- Generation 2: Arduino/sanguino based electronics. This is mainly in use today. You will have a setup similar to most of us.

- Generation 3 Electronics: This is the bleeding edge system. It is still under development but will arguably be easiest to setup and wire, since it incorporates a motherboard with easy wiring to each daughterboard. As it is barely available, it is not used much in the field yet (at the time of writing, april 2009). This may change quickly, however. Most of the electronics are surface mount.

Toolheads

The toolheads are the things that actually lay down the build material.

Currently, there is only one toolhead that is ready for general use, the Thermoplastic Extruder. However, eventually we would like to support many different toolheads from simple markers for drawing to support material extruders to paste extruder to lasers for cutting/sintering to wax deposition heads for doing metal casting. If you have a toolhead that does not heavily stress the cartesian bot, then it would be well suited for the RepRap platform.

Read more on the toolheads system.

Cartesian robot

Cartesian Assembly (Mechanical)

Click on the heading, folks. It's all in there.

Cartesian Assembly (Electrical)

The cartesian robot is mechanical element of Darwin. The assembly moves the tool heads around in the X & Y planes to print each layer shape and drops the Z axis down one increment when each layer is completed. Follow the links above to find out what parts you need, and how to put them all together...

Printing in 3D

Tweaking

You now need to tweak the software so that your hardware can print coherently. The parameters can be accessed by running the RepRap software and clicking on File -> Preferences. It is probably best to experiment with a simple STL.

Documentation for these parameters can be found here.

A guide to calibrating your machine using these parameters can be found here.

First Printing - Cheers!

If you've successfully assembled and tweaked everything and are ready to take the plunge, load up this file into the RepRap build area and start the job. After X minutes a few small cylinders suitable for drinking should appear. Gather your friends and fill them with your age-appropriate celebratory substance of choice. Say a cheesy line, and drink. This will demonstrate some excellent properties of your new machine: that the axes work, your extruder works, and the plastic seal is watertight. Welcome to The Future.

Feeding The Extruder

For experiments and calibration, you can just poke a metre or so of filament into the extruder. To make substantial components you'll either have to keep joining more bits on, or use a spool mounted so that it can feed the extruder without kinks. One approach is detailed here

Spare Parts and Replication

Now that you have a working machine that is well supplied with raw material, make one each of all the component parts of your machine and put them in a cardboard box on a shelf in a cool dry place. In the future if anything breaks, you'll then have the right spare part. If that happens, replace the part, make another, and put that back in the box. In addition to making copies of itself, RepRap can, of course, repair itself...

Also, don't forget to make two machines for friends or colleagues. It's by no means required, but it is definitely in the spirit of the project. The project is free (as in speech), but unfortunately real stuff costs money, so the common etiquette is to pay for raw materials / shipping / construction time.

Supply

In fact, since its in the group's best interest, we will probably be doing group buys in the future through the RepRap Research Foundation (RRRF). The more people we get, the better prices we can negotiate. Additionally, since it is often easiest to buy as an individual, we will also be listing suppliers where you can get parts. This is a good thing since with this shared knowledge, we'll be able to compare prices as an internet community and if someone finds a supplier with the lowest cost with a compatible part, then we can highlight that source and everyone will benefit from the savings. Economics dictates that the larger this project gets, the cheaper its components will be.

-- Main.ZachSmith - 01 Feb 2007