User:Dslewicki

Contents

- 1 Introduction

- 2 BLOGS

- 2.1 Blog Number One

- 2.2 Blog Number Two

- 2.3 Blog Number Three

- 2.4 Blog Number Four

- 2.5 Blog Number Five

- 2.6 Blog Number Six

- 2.7 Blog Number Seven

- 2.8 Blog Number Eight

- 2.9 Blog Number Ten

- 2.10 Blog Number Eleven

- 2.11 Blog Number Twelve

- 2.12 Blog Number Thirteen

- 2.13 Blog Number Fourteen

- 2.14 Blog Number Fifteen

Introduction

My name is Dimitri Lewicki, a student at the Pennsylvania State University Schreyer Honors College in my second year. I am majoring in Mechanical Engineering and am pursuing minors in Engineering Entrepreneurship and German. My career goals include product development and serial entrepreneurship. I intend to graduate May 2016.

BLOGS

Weekly blogs will be written based on prompts provided by the professor. These blogs are often related to RepRap.

Blog Number One

Part A

An item that is amazing/beautiful

There is a really beautiful vase made up of external curves and crevasses that are apparently parametric sinewaves. It curves out at the bottom and tapers toward the top. Here is the link: http://www.thingiverse.com/thing:145913

Part B

An item that is funny or strange

I found a bow tie that you can tie to your shoe as a fashion piece. It looks really weird, especially on the shoes that the guy is wearing in the picture. Here is a link to the page: http://www.thingiverse.com/thing:145406

Part C

An item that is useless

Someone made a miniature model of a smart car. I see no purpose in this, and certainly does not have the "wow-factor" that a model of a supercar would have. Here is the link: http://www.thingiverse.com/thing:141481

Part D

An item that is useful

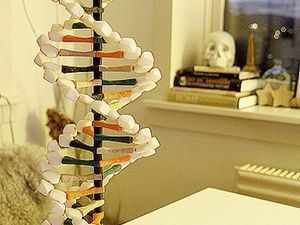

I found a DNA Helix model. Someone printed all the cross rungs and the outlying end pieces. Then they assembled them around a metal rod. This is useful for educational purposes. Her is the link: http://www.thingiverse.com/thing:145329

Part E

The best printable Raspberry Pi case I could find

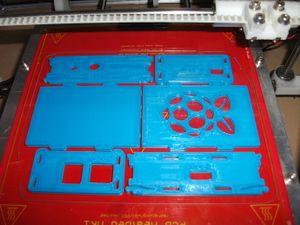

The best one I could find got good reviews and many likes (60), which is more than a lot of the other cases. Also, the top and bottom of the case are interchangeable, so the design is quite versatile. Many users have printed the design. Here is the link: http://www.thingiverse.com/thing:26922/#comments

None of these designs surprise me, but I could see that some of them would need support material to be printed properly.

Blog Number Two

I am currently working on two projects for the course. The first is to finish up the Yellow/Green printer. This is going pretty well so far, though we did break one part the other day and had to replace it. But we are making headway with determining what all has to be done to finish it mechanically by looking at other finished printers. We started printing new parts for it on Tuesday and will continue doing that in the next class.

The other mission I am working on is to fix up and finish the Solidworks model of the Open Hybrid Mendel printer design. The fixing up entails converting the STL part files into editable Solidworks part files, because some of the custom parts are only in STL format right now. I am going to look into programs that could possibly convert the STL files back into Solidworks part files. But I think it may just be easier to remake them in Solidworks, because all the features would be lost in a conversion from STL to SLDPRT format. After fixing all the parts and completing a final assembly, I can potentially create a set of assembly instructions that would instruct users on how to make an OHM printer from scratch.

Another project I may want to work on after these projects is the portable 3D printer solar cart. I love the idea of being able to push a 3D printer around campus and print objects for people, all the while running off of solar power. My question about this would be if we need DC batteries, in case the sun goes behind clouds and there isn't enough sun power for a short period of time. I do not know much about solar power, so this project would be really enlightening for me.

Blog Number Three

I think Tom Stewart's blog is very well done. The first blog post is the most in depth I have seen thus far, and the pictures are good. I also like his second blog post. It is very in depth as well, and the topic he discusses about the corporate use of 3D printers is well thought out and detailed. If I were to make a suggestion, it would be that his second blog post should be broken up into multiple paragraphs, because it is long for one paragraph. That would make it easier to read.

In regards to blogs that could use improvement, I think if Steven Rekstad added pictures to his first blog, it would make it look a lot better. Pictures draw in readers and add color to a page so it's not as boring. Otherwise I think his blog is great.

Blog Number Four

My fourth blog will involve me commenting about this video: [1]

The model for Arduino is to provide an open source design of a simple, affordable computer board that beginners can use and learn on cheaply (they related it to a textbook). They also provide the software to start using it, and it works on Linux, Windows, and Mac. As of the time of the lecture (2011), Arduino was a 5 man operation. For a while they did not even do any marketing. Everything was over web communities and by word of mouth. They make their money mostly from delivering consulting and design services to people working on their platform.

With regards to RepRap, it was not apparent to me how they make money, if they do, but they do gain an amazing wealth in general terms in return for giving out their design. That wealth is the value of 7 billion designers who contribute to the RepRap community.

Another company that runs off of the open sources, "give it away," model is Wikipedia. They ask for funding and donations from its users. That is how they manage to stay in business without putting advertising on their website.

I like the whole opensource community concept that has arisen with the internet age, but if I were to start a company (which I plan on doing down the road) I would not shoot for it employing the "give everything away" model.

Blog Number Five

I see no patentable aspects to any of the Thingiverse items from my first blog post except for the Raspberry Pi case. All of the other items, including the vase, the shoe bow ties, the model car, and the DNA Helix are not unique in their function. The Raspberry Pi case, however, does have a function that may be unique compared to the other options of Raspberry Pi cases out there.

In terms of items that may be copyrightable, I think the only one that has copyrightable aspects is the sine wave vase, because it has an artistic design to it that seems to be original. The model car and the DNA Helix are not designs, nor are they original. And the shoe bow ties are not very original. The idea of them may be, but the design is not.

Looking through some of my classmates' Thingiverse items from their blogs, I found one that seems to be very patentable. It's a "quadrocopter" from Brandon Leshchinskiy's Blog. If it is the original 3D printable "quadrocopter" design or if it has some unique vital feature that sets it apart from other 3D printable "quadrocopters", then I think it has potential to be patented. And of course, as I was saying about the Raspberry Pi case on my blog, Brandon's Raspberry Pi case may have the potential to be patented as well. It seems to have some unique features which add functionality.

There are two reasons, one legal and one cultural, why one would be interested in the licensing of non-copyrightable files. The legal benefit is that the terms of the license today will be the terms forever, no matter how much copyright law changes in the future. As long as you understand that you don't have control over the non-copyrightable parts just by granting the license, there is little downside to protecting the status of the project. The cultural reason is that licensing can be a signal to others even if it isn't legally enforceable. Creative Commons licenses tell others that the creator wants to involve her work in a growing network of creativity. This sends a message to the community that they can build upon the object.

Blog Number Six

In addition to what I said in my fifth blog, I want to bring the reader's attention to several more points which I neglected to include in that blog post.

The first point is the idea that the model car design from Thingiverse might be a copyright or trademark infringement. The reason for that is because the name specifies that the car is a Smart Car, which is trademarked. And the model is displaying Smart Car's design which is probably copyrighted.

And there are a few more points I want to make about the benefits of licensing non-copyrightable files. One additional point I want to make is about the legal reasoning for why I would be interested in licensing non-copyrightable files. And that additional point is that it makes clear what the uses of the design are. And the overarching idea for the benefits of the legalities is that licensing is a "future-proofing" tactic. The overarching idea for the benefits of the cultural aspects is that licensing promotes collaborative open source online communities where people improve upon each other's ideas and contributions.

Blog Number Seven

For this blog I will be discussing an article about an artist, Shane Hope, who is using 3D printers to create art. He uses four RepRaps in his studio to constantly be working on multiple projects. In order to create the art, he starts by searching for interesting CAD models on the Protein Data Bank, a database of CAD files for building living organisms. Since these models are not complex and weird enough, Shane then writes Python scripts to alter the shapes until an interesting design is reached. He then goes to image editing software to combine the models and create a colorful, complex, and creative layout for a painting.

While he is printing his paintings, he will mess with the settings and change such things as printer speed mid-way through a print job. This adds more complexity and randomness to the art piece. He also colors on the plastic filament with marker and fuses different color filaments together in order to produce more interesting color patterns.

This story is claiming to be important because of its ties to the future. Shane Hope claims that his art is a good visual representation, on a large scale, of how future 3D printing will work. Instead of metal extruders that melt plastic and spit it out, 3D printers will be forming objects from the molecular level, adding molecules one by one until the object is formed. Shane says this idea may be too far fetched and complicated for some to wrap their heads around, but that his art is a step forward in educating people about that concept of futuristic 3D printing. This take on his art may be exaggerating its importance, but it is an interesting thought about the future of 3D printing and how it can be easily visualized.

On the other hand, this article is not introducing anything new to the 3D world, except an example of an interesting use of 3D printers that does not get talked about much: creating art. In terms of advancements, this article is not revealing anything revolutionary in the 3D printing world. In the art world, this may be a new concept of how to do art, but it does not alter the 3D printing industry.

What I take away from this article is an interesting new art form, one created from machines, not humans. The human is not altering his work of art directly, except when he colors on and mixes filaments and when he adds paint touch-ups at the end. Instead he alters his art through a computer. He writes code and changes printer settings to create his desired design. So essentially what is different about this art form from more traditional forms such as painting, sculpting, and sketching is that the design is created through programmed calculations. The input into the design are calculations; some are random and some are intentional, but the human input is through the form of specific computer commands. This is not to say that the art isn't creative and beautiful, it's just a different approach to creating funky art.

Blog Number Eight

Part A) The first project from AMRI is about open source SLS 3D printing. A link to it can be found here. Andreas Bastian is heading the project and he is building an open source SLS 3D printer. He says he as built one before and is using what he learned from that experience to advance this project. He even has created a device for making powders out of various materials for the printer to print with. I think this project is very interesting and valuable, because I have articles before about how hard and expensive it is to make an open source SLS 3D printer. If he can start the ball rolling with an affordable working SLS machine, then that would be a major contribution to the 3D printing community.

The second project from AMRI is about ink-jet printing genetically modified living bacteria. A link to it can be found here. This project is funded by UltiMachine and taking place at Rice University. UltiMachine bought 6 InkShields and 11 ink-jet heads for the project. The project outline is to improve ink jet printing with RepRap technologies to be used both for DIY purposes and research. This project is valuable because I have read an article before about how the printing of bacteria may aid in bacteria research and understanding the living organisms better.

The third project is called: digital light projection (DLP) photolithography of plastics and hydrogels. A link to it can be found here.The project is to resurrect another near dead project called 3DLPrint. He is rejuvenating it under the name Open3DLP. His project entails creating a DLP 3D printer. This is a valuable project because he is taking the prior knowledge to make a printer that hopefully solves some of the ailments that these printers have had in the past.

The fourth project is called: bacterial cellstruder for synthetic biology studies. A link to it can be found here. This project was to develop a 20mL syringe extruder that can precisely lay down liquid at the microliter level. An example print they have done with this extruder are E. Coli cells glowing with green fluorescent protein. The value of this project is allowing for more research to be done on bacteria.

Part B) Besides the following adjectives: Open Source, Design, Learning, Education, Research, Additive Manufacturing, and Fabrication, here are some adjectives I can think of that broadly describe the class and what we are doing and what others are doing elsewhere: Experimental, Brainstorming, Discovery, and Pioneering.

Part C) In this section I am going to be brainstorming acronyms that describe our class and what we are doing. Here is an example of a group that uses an acronym to describes itself. Some acronyms I have thought of include the following: REAM: Research and Education in Additive Manufacturing and BOSS: Brainstorming Open Source Solutions

Blog Number Ten

I am going to be doing research about Jeffrey R. Immelt and Terry Guo for this blog. Jeffrey is currently the CEO and Chairman of the Board at General Electric. In February 2009 he was appointed head of Obama's Economic Advisory Board, the people who were to advise Obama on fixing the economic crisis. And in January 2011 Obama appointed Jeffrey chairman of his outside panel of economic advisers. Jeffrey is in full support of replacing traditional manufacturing (including GE's) with additive manufacturing where it is practical and possible. He believes this will give America a competitive edge globally. He probably believes this because he is at the helm of a huge international corporation that can afford the newest developments in additive manufacturing and reap its benefits. Terry Guo founded Foxconn, a huge manufacturing company that contracts electronics manufacturing for other companies such as Apple, Inc. They are a prime example of outsourced manufacturing. Terry has called 3D printing a gimmick. He does not think it is nearly as good as people are hyping it to be. I believe he feels this way because he is involved with electronics manufacturing, which 3D printing is not very applicable to at this time. So his company Foxconn does not have very much use for 3D printing. That is why he does not feel excited about the technology. I also think that 3D printing is not very important to him because his labor costs are very small compared to other manufacturing facilities around the world. He can hire people on extremely low wages. So the benefit of reduced manual labor that 3D printing brings to manufacturing facilities would not have as big an impact on his company.

Blog Number Eleven

For this blog I will be talking about some of the frustrations I have had with the printers. Several times I have tried to print something and the printer will not respond at all, or won't connect to the computer. This has typically been due to an unplugged wire. This bothers me because there are so many disorganized wires around the printers and so many electronics hanging around that it often takes a little while to trace the wires and figure out what is unplugged. But it is usually an easy fix. Sometimes the construction or design of the printed parts on the printer frustrate me. I have been involved with putting the yellow printer together and have encountered many parts that won't line up or are really hard to assemble due to the nature of the design. I have to print out more parts to solve these issues. But with a recent issue I encountered I am planning to redesign the part to make assembly easier. It is the t-shaped part on the undercarriage of the bed that connects the all thread piece to the large plastic piece that holds the bearings. The t-shaped part tapers to a point underneath it and this inhibits the ease of snapping the bearings around the x-axis movement rods. I think the taper, which increases the thickness of the part, is pointless.

Another problem which was brought to my attention was the extruder on the white printer was flexing up and down. This was due to the polycarbonate mount for the extruder bending, because it is very thin (about 3/16). The fix was to make another polycarbonate mount and slide on top of the other to increase the firmness. I believe this solution has been working so far.

Blog Number Twelve

I really enjoyed reading about OpenScad in these articles: [2] and [3]. One of the strengths I see for a platform like OpenScad is its community. With a strong community of users, it is easy to get help and ask questions. The improvements made to the program are also more founded in the end user. This program seems to be good for very specific and rigid designs, because the user giving the program specific, detailed instructions. This means, though, that the user is not interacting with the objects directly. They have to communicate through the medium of a programming language and that does not allow for as much artistic, creative design. In a program like Solidworks the user works and controls the objects directly, which I think gives the user opportunity for more creative design. It would seem to me, though I’ve never used OpenScad, that Solidworks has more versatile tools for creating the shape the user wants, making it a better choice for more complex shapes and designs.

Though I am very comfortable with Solidworks, I am tempted to try OpenScad because of how different it is from Solidworks. And that process of taking an image and making a model from it is also very intriguing. I think that would be fun to try with pictures of landscapes, if the program has the ability to understand the “3-dimensionality” of a 2-D photo.

Blog Number Thirteen

In this post I will be talking about this video. This would be very interesting to incorporate into 3D printers, because we could print simple circuit boards. Instead of having to use software and machines specifically designed for that, we could use Solidworks to make the layout and cheap open source 3D printers. The pen could be made as the second extruder on a dual extruder printer, and the physical circuit board could be printed around the ink circuitry. Screw holes and holes for the input and output plugs could be printed directly into the body of the circuit board.

This pen could also replace the ink jet of regular paper printers, to make a printer that prints very simple circuits on paper, which could be designed in Illustrator, or even Paint.

Blog Number Fourteen

I really like this design for a Rep Rap printer. Here is another link with pictures and video. It’s so much more open, which makes watching your print or fixing the printer easier. One concern I have with the design of it is with the stress put on the printed pieces that join the z-axis and x/y-axis (the one not moving the bed. If those printed parts aren’t strong enough, they could loosen (which would decrease the accuracy of the printer) or break over time. The OHM printers have a very rigid metal frame, and not as much stress being put on the printed parts.

I do like the design of the Smartrap Mini though. It seems like it would be a lot quicker to build and fix. And it just has a cleaner design overall in my opinion.

Blog Number Fifteen

The things that were new to me from this list are: food, drug paraphernalia, sex toys, an entire car, clothing like chainmail-like bikinis, DNA sequenced human masks, models of pregnant women’s fetuses, and surfboards. I am very confused about 3D printed food and would like to understand how those printers work.

I think there is opportunity for entrepreneurship in the common 3D printable goods industry. I think an interesting business model would be one that designs a bunch of 3D printable versions of commons products and then makes the designs available upon payment. I am not sure patent law would protect against people who want to make similar designs of their own available for free. I also think that designing an easy-to-use and easy-to-service printer for the masses would be good, but that industry has already been around for a while and has plenty of competition.