User:Kvk5287

Karol Kolc RepRap Wiki

Info, Blogs, Projects, more!

Contents

- 1 About Me

- 2 Weekly Blogs

- 3 Article Blogs

- 3.1 Article Blog #1

- 3.2 Article Blog #2

- 3.3 Article Blog #3

- 3.4 Article Blog #4

- 3.5 Article Blog #5

- 3.6 Article Blog #6

- 3.7 Article Blog #7

- 3.8 Article Blog #8

- 3.9 Article Blog #9

- 3.10 Article Blog #10

- 3.11 Article Blog #11

- 3.12 Article Blog #12

- 3.13 Article Blog #13

- 3.14 Article Blog #14

- 3.15 Article Blog #15

About Me

| RepRap User: Karol Kolc | ||

|---|---|---|

|

||

| University | Penn State | |

| Class of | 2016 | |

| Major | Aerospace Engineering | |

| Partner | Devin O'Donnell | |

| Printer | Clear Printer | |

Introduction

During Fall 2014 I am taking the course of EDSGN 497J which is the open source 3-D printing course. Follow me on my blog where I update status on the printer that my team is working on and interesting facts about additive manufacturing and related material.

Weekly Blogs

Blog #1

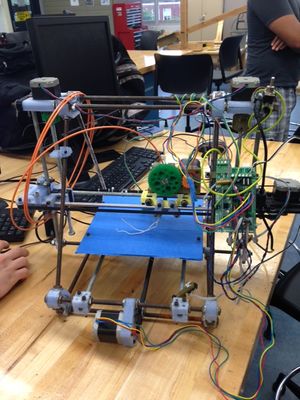

Class has finally started and work has begun on our printers. We have been assigned the clear printer to be working on for the remainder of the semester. We hope that in the 15 class weeks we will become successful in turning the printer into a working reality. Looking upon the wiki website, it turns out that our printer was actually running for a time in 2011 before it was deemed to be too damaged. This gave us some sign of relief that the printer at one point in its lifetime was actually running and operating. I am happy to say that our group has the capability and skills to make this into a fantastic group project. There is still soo much to learn!

Blog #2

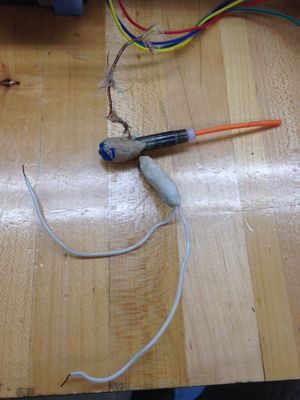

Upon inspection of our printer we have found many different types of problems that need to be fixed in order to get the printer to completion. Among these problems was a chipped off extruder belt arm and a damaged filament nozzle. As of right now, these are the only two things that need to be replaced in the printer before we can truly see if the circuits and wiring actually runs. Disassembling the nozzle we have found corrupt and frail wiring that will need to be replaced and re soldered. Devin will do this part while I find a way to replace the small arm piece to the printer. Upon discussion with the TA, Ian, we will make a decision whether or not to replace the nozzle or try and fix it. However, in the meantime, here is a picture of the nozzle, it is in rough shape.

Blog #3

This week we have finally gone out of our comfort zones and actually came for 2-3 hours on a Friday afternoon to get the ball rolling and get the arm piece replaced. From the wiki, we have downloaded the needed STL files to be a perfect fit for our printer and have uploaded to one of the working arduino computers. From there we then setup the gcode needed to run the print. We initially have problems finding the software to convert the files into the printer interface but then were successful to get the print started. The print alone took about one hour and the rest of our time was tinkering and setting up the printer/software. We have finally got a hand of the printer technologies and it was a sight to see a first test print of the arm finally go! These printers take awhile to setup but are worth it in the end!

Blog #4

Well, here we are back to the test part we created. We initially had high hopes that at least the test part that we printed would be almost functional, but we were wrong and there is still too much to learn. The printing at first started out very well but towards the end of the print cycle, the printer was not configured enough to get a precise measurement for the top layer and the part became deformed. Looking back at our experience, we had learned much about how the printers run and operate and we got a fantastic learning experience. From previous consultation with the TA, it will now go back and reprint the part but this time with advanced settings and squaring the printer, which is just adjusting the parts to make a tight tolerance. After the squaring, it are sure that the printer will cooperate this time around to print the part!

Blog #5

Well, we are back to squaring the printers. Squaring is an essential process because since plastic and wood pieces on the printer often times get deformed an loosened. This is a small hassle to do,but once done properly the printer can operate more efficiently and cooperate with better prints. In order to square a printer, one needs to use calipers and measurement tape to set both sides, left/right and front/back of the printer to same dimensions. By dimensions, it meant the parts on the external connecting rods that hold the printer in place. These parts need to be adjusted to a same or close value of the space between them. This requires measuring the distances and then unscrewing and realigning the components into a tight fit. This was a easy process to do and required just some time to complete. Now since the working printer is squared off, we can then continue onto the print for our arm piece. We are optimistic that it will work this time around!

Blog #6

Well, we went back to the drawing board and got a new arm piece printed for our printer. We learned our mistakes and this time we gave in to a accurate rendering and printed model of the arm. The ways we improved the print was to square off the working class printer and scale the STL model to optimal settings so the printer interface can actually properly print the top layers of the model. The print came out after much better with a improved tolerance level and no deformation in the top layer. Because of this, we now have a usable arm piece for our printer. That being done, it was finally time to attach the arm piece to the extruder belt and test out the tensions. Using a ziptie and complete tension, the arm piece has been finally installed. Now, all there is left is to test all the components and hopefully start getting to print and using our own printer. This is an exciting time because now, our printer hopefully has all the working components to work!

Blog #7

After testing all the control surfaces with the belt attached to the new arm peice with printed out, it was determined that a few defective parts needed to be replaced. The first being the extruder motor that needed to be swapped out with a brand new one. The old motor wouldn't get any input from the arduino board. After this motor has been replaced the control surfaces has been re checked one more time and seemed to be working optimally. The last thing on our checklist was then to replace the faulty power cable connecting the arduino, after much debate about whether or not to solder the remaining ports to make it more usable, we then just finally decided to replace it with a more reliable cable. Now that the control surfaces are all checked out, we can finally try and optimize the printer for a test print.

Blog #8

Last time we went through the printer, we replaced components and checked over the control surfaces to see if they respond by the board computer. Now it is time to soon do a test print and get the printer to optimized for tight tolerance printing. In order to do this we have to square off our own printer. The squaring process as described earlier in the blog if a crucial and important step to get optimal prints. Without a printer being squared, the print can come out to be deformed or even worse damaged by the extruder nozzle. Under careful squaring of the printer, we have gotten the measurements as close as possible to both sides of the printer. Now that the final step was to square of the printer, we can finally get into printing!

Blog #9

The printer itself is working very well at this point in time and the hard work as finally paid off. The printer itself with many problems with hot tips and damaged parts in the past is gone now. No longer do we have to do much repairs to the infrastructure but process routine maintenance every once in a while for example squaring or replacing worn out components. We have finally gone in and started to do a test piece. A simple test will show how the printer currently runs and operates with the noticed changes into components. The print test we printed is a simple part of cylindrical shape. The printer actually started out with the piece very well and finished it almost perfectly. I am now optimistic that the printer can have a future where many other users can keep using it and enjoying its features. The next time that we meet, we will doing complex print service parts and we will see how the clear printer holds out!

Blog #10

Well class is finally wrapping up and I have to say that this was one of the most interesting and unique classes I have ever taken. Over the course of the semester I have learned much about additive manufacturing and of course the 3d printing process and design. The coolest part of the course was to actually go in and have a hands on perspective building and fixing the printers. That is truly a good way to study and learn because it is just theory until you apply it to real life. As for our team printer, the printer has been fixed up to optimal capabilities and hence no problems as of right now. Future users and course teams will enjoy a decent printer to use. The only things needed to maintain the printer is to square it off occasionally and replace damaged parts. The printer extrude nozzle is in okay shape but gets the job done. The last few things we are finishing up is printing print service parts for the Printrverse website and of course submitting it to customers. I have to say that is was my most favorite class up to date.

Article Blogs

Article Blog #1

One of the most interesting things that I have seen with 3d printing is that no matter what the applications are, it is always much more convenient and cheaper than standard manufacturing. With this type of new technologies, printing materials to army clothes and armor can make it much more comfortable for solider to move around on the battlefield and of course day to day functions and activities. However what is truly remarkable is that there can be a mixture of different types of materials built right into the fabric to make it a more reliable system of clothing. I can also see more more practical applications of this for example fixing damaged armor of soldiers. This however would require some type of material research to actual built a strong material that can withstand any damage in the battlefield. As of right now with the current technology this would be hard to do but maybe one day in the near future this can be possible. Regardless of the many applications that the army is using for 3d printing, the technology is being tested and developed slowly year after year to a strong progression!

Link found here:link

Article Blog #2

Yet another interesting aerospace application that the world of 3d printing is getting itself into. With additive manufacturing methods used in flight configurations this proves that even in the conditions of spaceflight, 3d printing has proven another forefront. The most interesting thing here is that the combinations of the printed pieces are being used to minimize the parts that are used to assemble this camera. This is one of the strong points of 3d printing, using rebuilt configurations possible to assemble a complex object as simply as possible. This is due to the nature of the printers allowing it to print many different types of materials in one piece. This makes the design much more simpler and elegant. This is not just one of Nasa's examples of 3d printing, earlier last year they used different structure designs to fix parts for the international space station. This would reduce space for cargo parts that are being sent to the space station every few months and rather just rely on making fixes to damaged materials. This saves time, effort and cost to makes fixes this way. NASA has come a long way to test different 3d printing technologies and materials and leading the forefront to a positive future.

Link found here:link

Article Blog #3

Paste extrude technology is causing a very big idea to immerse in the 3d printing community. There is much research going on right now to get into different types of materials within 3d printing. One of the most interesting is using paste technology exactly like in the article. Paste technology is different because you can 3d print with mixed material in a easier environment. You can get into cooking, wall fills and much more. One of the examples is that you can 3d print cakes and other baked goodies within 3d printing. This would be much more effective for decorations that would be very hard to do by hand. Out of this can come out crazy designs, food structures and other interesting food products. The best thing that this is that you would only have to program the design into the printer and let it run into completion. No hassles and no hard to reach places/designs. The other applications of this is to make wall designs for construction and many other types of structures. If you can think of something elaborate to do, then it can be possible with a 3d printer. The guys from the kick-starter have a great team and ideal to make it a reality.

Link found here:link

Article Blog #4

What a very interesting article, probably the most unique I have read so far. I knew that 3d printing foods would some day become a reality but I don't think that time has come yet to be now. I find the concept of 3d printed foods very weird and disturbing to a point. The article even explained that you can make a eatable 3d printed lamp. I don't know about what people would eat from 3d printed objects but I would not eat a lamp. Besides the point of the weird objects you can make, the technology for 3d objects is not even close. To make for example a burger, like the article suggests, you would need multiple extrude nozzles of foods already stored. I understand that sometimes the need to 3d print some foods, but why change a regular burger made with fresh wholesome real materials. However, this type of technology can be indeed useful for some applications such as for elders. There was a previous article some while back that they were experimenting 3d printing food for elders who cannot chew hard foods because of dental problems. This to me makes more sense and is a better alternative. Regardless of the applications, the article did show and explain some useful objects like Lego shaped cereal and other cool things that would be difficult to make using convenient methods of cooking/preparing.

Link found here:link

Article Blog #5

Finally the article that I have spoken of earlier, nursing homes using 3d printed foods for elders. This has very good applications because elders have problem eating hard foods that would indeed a difficult task. The items printed as described in the article as actually decently presented as real food items and shaped like them too. Instead of serving the elders mush of non appetizing foods, this can make food look and taste as good as the real deal. If the company combined hard to eat menu items as well as real foods that are easy to eat such as mash potatoes and apple sauce, then they might have a shot to creating something great. The fresh ingredients aspect actually makes the food taste the same as it would be prepared like the real thing. The pureed foods times might at times just look like blank non vivid food objects but if they create these 3d printing ones, they can make it into any shape and texture that they want. This to me is a great success and I hope the company succeeds at creating what is hope to be a growing market. As mentioned in my other blog post, this method and applications and 3d printing foods actually makes a lot of sense instead of creating weird shaped objects that a normal person can eat on a daily basis.

Link found here:link

Article Blog #6

Yet another food article but this one is the most interesting one. 3d printing foods at NASA at been in research and development stage for a very long time. The potential and great interest in creating the food items can cost space exploration time and money especially in the preparation stages. Right now the standard way of preserving food is using freeze dried food items that are not good in taste and have very weird looks(tube like) substances. This is fine for NASA to be using these, but they have been for the past 30 years without changes. Changing the way astronautics cook and store food can even have a great impact on space exploration. NASA engineers can make 3d printers that can be used on long distance travel to lets say Mars or other deep space exploration. Having limited supplies on these missions can in fact hinder the materials and supplies needed to have a successful life sustaining environment. We wouldn't want our astronauts to run out of food some 401 million kilometers away from earth. If astronauts can make their own food with limited supplies than this can solve the problem of food preparation. I sure hope that sometime in the near future this can be possible because the technology is there but now the applications need to be applied.

Link found here:link

Article Blog #7

This is actually the most heated evidence of 3d printing out there today. What will actually happen to jobs as the 3d printing industry starts to grow big and strong.It is supposed that manufacturing jobs would sure to be in decline and an entire unemployed workers would be bounded to happen. However, lets suppose that this is not the case. Sure economists may research how layoffs would sure to be happening sometime soon because of 3d printing and additive manufacturing, but lets just say the market doesn't change drastically but rather takes a complete turn in a different direction. Where wold that put workers and industry then. How come we cant assume that just maybe workers will just incorporate 3d printing into their daily jobs rather just being replaced by them. This exact scare came when music downloads on the internet. People became obsessed that artists would just lose money to getting their latest album or songs downloaded rather than being bought a CD from the store. Instead now music artists just use the internet to sell their music and still money. This same thing can be done with 3d printing. We can have a 3d printing revolution where they are used as a tool for working to creating more efficient parts, faster labor and of course ease of job mentality. This is the ideal standpoint of 3d printers and hopefully in the near future this can happen. Even today, additive manufacturing is still used as a tool rather than replacement.

Link found here:link

Article Blog #8

As an aerospace engineering student myself, I find it fascinating what can be done to improve the aerospace industry especially in the manufacturing. One of the newest technologies of additive manufacturing can help achieve ways to produce advanced aerospace components by 3D printing. Companies such as GE are taking in huge investments on this new type of technology to limit costs, production control procedures and of course general usability to print materials that are stronger, lighter and cheaper. Having an ideal mindset to make these new components made of new experimental materials that can not only improve aircraft but also change the lifespan of different models. The companies that are running the forefront now will be the primary technology epicenters for the upcoming future where additive manufacturing will become more readily available through cost and testing of different processes. In my prediction, in a short span of 10 years, many components of aircraft especially in cabin components will be 3D printed to make ease in assembly and production.

Link found here:link

Article Blog #9

Once again, the jet engine design has caught my attention. This week I have given a presentation of the jet engine technologies that the aerospace industry is using and the designs of people working on real engines that are 3d printed from their homes! This would be an extremely difficult but rewarding project to actually print the jet engine parts, fit them all together and turn the engine on! The jet engine would be powered by compressed air that would lead it into the compressor and turbines to make it spin. Upon looking at the design, the tolerances for this print would have to be tight because if not, the high pressure of the air would actually tear the engine apart! Regardless of the problems that arise from this, the aerospace applications have once again shown me that there is too many cool and interesting aspects with this technology.

Link found here:link

Article Blog #10

Something very interesting has been just recently released by HP this past month. It is called the HP sprout computer and this will be the biggest revolutionary change in computer interface and 3d printing. The HP sprout is a typical desktop computer however there many distinct features that make it much more different. First, there are two screens, one primary and another for the workshop. The workshop screen is actually projected onto a touchscreen mat on the table. This is optimal because you can see one screen while you work on another. This layout was given primary to designers so they can work on a project on one viewpoint and then switch over to another. BUT, the most important aspect of this computer is that it has a built in 3d scanner! This scanner is so revolutionary that it will be revolutionize the way we 3d print and import objects into computers. The scanner is a accurate device that you actually can put any random object on the mat and it will complete a 3d model or CAD file of the exact object. This a breakthrough in technology because now we can scan objects and get an accurate model without spending time building a CAD file!

Link found here:link

Article Blog #11

Just recently the European space agency created a plan to actually 3d print a giant moon base in the near future. 3d rovers to actually construct the structure of the moon base would save time and money for a habitat. The rovers would be sent to the lunar surface and would actually outline a moon structure using moon rocks and of course special printing material to construct it in a few short months. This way the astronauts can actually come and finish up the habitat by finishing key elements such as oxygen and electricity etc. I think this is a very good plan to do especially if it would save time and money. The rovers and robots are actually been patented into a plan modeled by special habitat ideas. The only thing that needs to be done now is actually convince the general public to pursue this mission and that could be quite the feat especially when funding is very tight around the space programs currently. The government will not fund these type of missions which leads to only private funding.

Link found here:link

Article Blog #12

The University of Toronto department of mechanics and 3d printing are creating easy and relatively cheap 3d printed limbs and leg prosthetic parts. This isnt a relatively new process considering on the first applications of 3d printing has been originally centered on biomedical aspects. However, what is different about this is that they are doing designs for poverty region in Uganda and other African countries. These printers will hopefully one day transition into regions where there are limited hospitals and medical support for patients. These printers can make cheap parts that can be proven quite useful for the patients who cannot afford much. What is great about this, is the more research that goes into it, there more applicable this can be become in the eyes of medical doctors and hopefully one day from the comfort of homes. To give some comparison, a standard prosthetic can cost more than $100,000 but with this technology it can reach only a small fraction of that price to make it easy to use and replace.

Link found here:link

Article Blog #13

A last final article summarizing the advantages and of course the different uses of 3d printing in the Aerospace industry. Printing different components in the near future can be possible for different designs and features of jet engines, aircraft wings and of course cabin parts. Currently, the Boeing 787 has over 30 printed parts in the cabin and in General Electrics engines which is a current record over the past. Soon on demand part manufacturing can be used and created by airliners to cause a demand of on the go parts that are worn and torn. These parts can be simply printed in the warehouse without having to purchase and distribute them throughout the country. This in turn can cause manufacturing jobs to diminish or a rapid trend of new design engineer opening positions in many different companies. The possibilities of using these parts in airlines or even space missions can be spectacular and of course save time and money in the long run. The future of addictive manufacturing will soon be used in many industries and very soon primarily in aerospace.

Link found here:link

Article Blog #14

IKEA has been known to sell very cheap and reliable products for the face on consumers. IKEA known for home decorating and furniture has many unique products that can change your home for the better. But now with 3d printing technology users can take their designs to the next level with artistic abilities. New user groups and communities on the internet have posted designs and configurations of many different IKEA products that can further their capacities. For example lets say you can buy a lamp at IKEA but at some products, their lamps only include the base model with no mounts. Now these user groups have created the files needed to actually print the lamp wall mount files using 3d printers. These ideas have sparked new interests and of course applications and potential of 3d printing can offer to a home decoration community.

Link found here:link

Article Blog #15

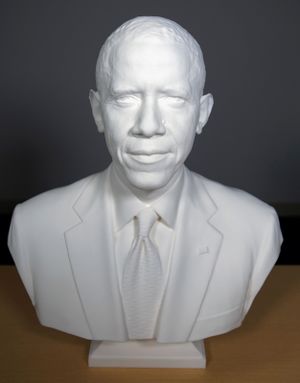

Just recently the Smithsonian museum has scanned and 3d printed President Obama's life size head. This new technology pinpoints accuracy with using over 50 LEDs and cameras that scan and operate into a cad model. This technology is currently being used to store and collect artifacts for the museum both digitally and physically. What is really more interesting is that using this software and portraits of past presidents, this scan can also replicate for example Abraham's Lincoln life size model of his head also without physically scanning it. This technology can capture models like no other software before to store for future generations to see. First there were pictures of presidents, then there were video and now 3d models that can actually be stored and even animated. This is truly amazing on what this software can do. Hopefully one day in the future it the software will even get to a more advanced level that can scan movements of people and capture them instead of a stand still models.

Link found here:link