User:MarkKeller22

Introduction

My name is Mark Keller and I am in my eighth semester at The Pennsylvania State University and I am majoring in Civil Engineering. I will graduating Spring 2014

BLOGS

Weekly blogs will be written based on prompts provided by the professor. These blogs are typically related RepRap in one way or another but not always directly.

Blog Number One

Part A

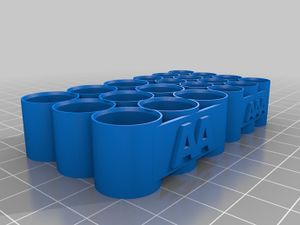

An item that is useful

In today's society headphones are almost a necessity. Whether it is for iPods, iPhones, MP3 players, or for use with your personal computer, they have become an everyday item. The problem with headphones, is that they are difficult to carry when not in use. They get tangled and can even become knotted. These ear bud holders eliminate the mess associated with shoving ear buds into your pocket or book bag. The STL file can be downloaded here.

An item that is artistic/beautiful

Beauty is in the eye of the beholder, and I have always had a fascination with airplanes. The bi-plane really is a thing of beauty. Two wings, a sleek design, and the way it is able to maneuver through the air all contribute to its beauty. The STL file can be downloaded here.

An item that is pointless/useless

An item that is funny/weird

The "shark with a fricken laser" is from the Austin Powers movies. As a kid, and even still today I watch those movies and laugh. The scenes with Dr. Evil talking about sharks with lasers is always a classic and makes me laugh every time. It is funny to see that somebody took the time to draw one that can be rapid prototyped. The STL file can be downloaded here.

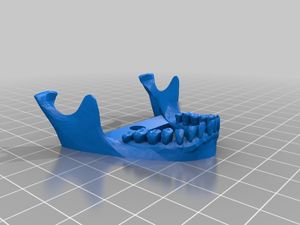

An item that is scary/strange

Although I can see some purpose for printing such an object, I feel that a lower jaw bone is a rather strange object to print. Typically if it were being used for medical purposes it would either be molded or an actual bone would be used, but to print one using a 3D printer for "personal use" just seems strange to me. The STL file can be downloaded here.

Part B

I do feel that I am a tinkerer. I love to take things apart and see how they work and then try to put them back together. I do feel that the amount of tinkering I do is decreasing as I get older. I do not have the same amount of free time to tinker as I did when I was younger, and my job does not require any tinkering. But when given the chance I thoroughly enjoy tinkering. My dad and my uncle's are all tinker. They grew up on a farm and had to fix things when they broke. Not only did they fix things, but they improved the equitment that they had, all through tinkering.

I agree with the argument. I particularly like the statement, "It’s that the notion that we can fix any problem or achieve any goal that we set for ourselves has deteriorated into a sanitized, corporatized version of what constitutes achievement." This directly relates to the fact that Americans have taken the replace it rather than fix it attitude. It is easier to just go out and replace something rather than fix what they have. This is the influence that corporate America has instilled upon us. The more we buy the more profit they make.

Things evolve through tinkering. No mater what field we are talking about, it is tinkering that pushes the progress. New things are created and old ideas are improved. So preserving the habitat, or allowing tinkering to continue to prosper will help us to "catch up" to where we should be.

The primary design principles that are the use of multidisciplinary brainstorming, finding out what do humans really want, and going beyond what you think you can do. It was pretty neat to see that someone who is as smart as Kelly and has created as many things as he has, is working on building a 3D printer, the same project that we are undertaking. I think that all of the principles can be applied to our work. We all think differently and using the minds of multiple individuals to complete a task helps it move that much quicker. Going beyond what you think you can do applies here as well. We may not all be programmers or good at physically building things, but we are all capable of doing it. This project will have us working on issues that we know nothing about, but we will, with struggle and time, be able to complete the tasks.

Blog Number Two

Mother Of All Demos:

When I first saw the mouse cursor move, it took me back to when I was younger. We had an old Macintosh computer I believe it was a mid to late 90s model, one of the grey boxes. That is what it looked like a grey box. We would fire it up and when moving the mouse, it had a similar lag to it like the one shown in the Douglas Engelbart video, Mother Of All Demos. It would have a string of pointers following as you moved the mouse until you would stop at a specific point. The program that Englebart was running sort of reminded me of Microsoft Word. Creating new files is similar to creating new documents. Each file can be saved and reopened at a later date. It can even open multiple files at one time. The copy and past functions are features that we use in every day life on computers. Sitting here in today's world, I take for granted all of the things that Englebart is demonstrating. I am incredibly impressed with technology that he is demonstrating. It is incredible to see how innovative people are and the technological feats that they have accomplished. At the time I don't believe that I would have been able to recognize the importance of what was being demonstrated. At that point, I don't think many people were doing work on computers so it might have been hard for everyone to visualize the importance, but had I been in the audience I would have recognized that copy and past is a useful feature as well as being able to save files.

Professor Richard Doyle: Open Source Futures

Blog Number Three

3D Printing in:

Civil Engineering:

In his TEDx Talk, Behrokh Khoshnevis discusses the application of 3D printing in the Civil Engineering world. He begins by explaining how construction, by today's methods, is hazardous, wasteful, corruption prone, and costly. He presents some facts on these issues such as, approximately 10,000 people are killed in construction accidents in this country. He then introduces the concept of using 3D printers in construction. I think that this idea is brilliant! But I do have some reservations about the idea. The concept is genius, using a printer/robot to perform all aspects of the construction process. My hesitation with this concept is that it will eliminate skilled labor jobs. Khoshnevis discusses this potential problem but his solution is that it will create jobs for a different set of people, those older and could not typically work in the construction industry. That is all well and good, but where does that leave the skilled laborers? My only other concern with the printing of buildings is a whole new style of repair will be necessary. It is inevitable that repairs will need to be made at some point, but fixing printed material is a new concept and not quite the same as repairing a building that utilized current construction methods. Overall though, the idea is fantastic and makes complete sense. Why not reduce the cost, waste and time of construction by using giant printers.

Bio Tech:

The article How 3D Printers Are Reshaping Medicine is really fascinating. The fact that we can print cell tissue in order to create new organs, vales, bone and even skin. It makes sense that printers would be used to make custom prosthetic limbs and hearing aids, but to print a new organ for somebody is and incredible medical marvel. Although the technology is not quite ready to be used in all instances, the fact that we are working towards the possibility of being able to create/print new human parts from man manipulated cells is mind boggling. I think that we can see the biggest change directly through the pharmaceutical companies gain by using 3D printing. Their costs are boosted/money is wasted in development due to the use of using 2D cell models. This gives a semi accurate analysis of how drugs will react with the human body. But by using 3D cell tissues generated by 3D printers will allow for a much more accurate representation and will decrease the cost of the research and ultimately decrease the cost of prescription drugs.

Food Science:

In the article, The Delicious Future: 3D Chocolate Printer Finally Available for Purchase, food printing is discussed. The technology is now available to the public. For a measly $4000 you can have your own 3D printer that will print edible chocolate creations. Typically ABS or PLA plastic is used as the printing material, but with advancements, chocolate can now be printed. I think that this is awesome. Although it is expensive, it is neat that you can personalize candy and make custom chocolates by transferring a drawing to an STL file to G Code finally to a printed product. Within reason, you can make any design that you want. It takes chocolate making to a whole new level.

Fashion:

After reading the Q & A with Iris Van Herpen and checking out some of the dresses that she has designed, I am truly in awe of the capabilities of 3D printing. The black dress was incredible. The intricacies of the design and the overall appearance of the dress was stunning. It is difficult to believe that it was printed rather then sewn. The encroachment into fashion is an excellent interdisciplinary mesh. Van Herpen discussed researching different materials as well as collaborating with scientists and architects in order to gain insight and the know how to literally create clothing. This shows that 3D printing is not just limited to those in the science field and that science is not limited to those in the science field. Like Van Herpen says, there are less restrictions when it comes to printing clothing, although there are some initial hurdles to over come. I think that it is neat to think that one day we will be able to buy a design file and then print our own cloths. It is completely wild and imaginative but sometimes hard to believe that it is even possible. Van Herpen has been working closely with the 3D printing industry to develop new methods and materials so that new levels of clothing printing can be reached. It is an excellent example of how progress is made.

Other Examples

I was watching TV the other day, and Season 6, Episode 14 of The Big Bang Theory two of the main characters, Rajesh Koothrappali and Howard Wolowitz purchase a used 3D printer. They want to use it for many different things, predominately work related, but they also print a whistle and action figures. Although it may not be a real instance, it is proof that 3D printing is on the up and up in today's society.

In this interviewwith Enrico Dini, 3D printing is discussed for buildings. Dini is a civil engineer with a passion for architecture. He feels limited in design by traditional construction methods so he invented and patented a full scale 3D printing method that uses epoxy to bind sand allowing him to print buildings in a cost effective manner. Ultimately his goal, after refinement of the printer, is to build a roundabout sculpture to be placed in Pisa, Italy.

Blog Number Four

Wow! The article about Liam's Robohand was inspiring. It is awesome that they were able to create a prosthetic using a 3D printer. The really neat thing is that the initial designs were created by two people hundreds of miles apart. Communicating by email, Ivan Owen and Richard Van As were able to design and trouble shoot prototypes, initially for Van As, but ultimately create the design for Liam. Owen and Van As prove that there are people out there who don't care about monetary gains but are truly out to help for the good of mankind. They keep the design and information open sourced so that it might continue to help those who cannot afford prosthetic limbs that run in the thousands of dollars. It is very admirable that do it this way, and continue to grow and look to push their creation with larger companies.

The technology for both open, and closed-sourced apparatus' are wildly incredible. In looking at a closed-sourced product, I came across a company called Touch Bionics. They created a prosthetic hand called the i-limb ultra. They claim that it is the most natural feeling and functional prosthetic hand on the market. Look and feel is one benefit of the closed-source hand. I would defend this by saying that prosthesis is a new comer in the open-source side of things. The hand designed and built by Owen and Van As is a completely functional unit, but it is crude and unrefined. The biggest difference between the two prosthetic hands, is that the model produced by Touch Bionics is computer based. It has numerous capabilities including variable digit grasp strength, automated hand grips, and the ability to pick up small objects. Currently, in the open-sourced model, it is pure mechanical operations. This is both a strength and a weakness. As far as a weakness goes, the open-source hand is very limited in its range of motion and physical capabilities. But as far as strengths go, a purely mechanical device is cheaper and can be fixed more easily. Cost wise, the open-source prosthetic is significantly less money than that of the closed-source hand. Any figures that I could find indicated that the Touch Bionics hand cost in excess of $6,000.

The prosthetic that Owen and Van As created can be found on Thingiverse. Information on their project can be seen at their blog, Coming Up Shorthanded. What Owen and Van As are really looking for is monetary donations to help keep the project going. They want to help as many people as they can, but financially it is not possible. One way that we can get involved is to visit the Fundraising Page. We can either make our own donations or we can put together our own fundraising efforts. Social media, such as Facebook and Twitter are excellent ways to help spread the word. By exposing society to this cause and soliciting funds, Owens and Van As could reach and ever surpass their goal of $50,000.

Blog Number Five

In my first blog, Blog Number One, I posted 5 3D printable objects that I found on Thingiverse. Of those five, I think that only the bi-plane has the possibility of having a patent/being copyrighted, but I doubt that it is. It is a model of what could be an actual design but looks very simplified, so it makes me skeptical. The ear bud holder would be my only other thought, but it seems like a "useful" object such as the article described. I wouldn't think that it would have a copyright/patent.

Blake Ziegler has a model of Abraham Lincoln that was scanned using a 3D scanner and then printed. Models/sculptures typically have copyrights associated with them. Due to the magnitude of importance of Abraham Lincoln, I'm sure that the original sculpture is copyrighted. Carina has two that items that are most definitely copyrighted. The first is a printed model of Notre-Dame de Reims. Architecture is automatically copyrighted. She also has Minions which are from the movie Dispicable Me. Things from movies are also copyrighted.There are two reasons why licensing, they are legal and cultural reasons. Looking at the legal perspective, granting a license now makes the usage conditions clear no matter how the copyright laws evolve. There are differences though, giving full permission vs. restrictive. Giving restrictive permission can cause more problems than it does good. From the cultural stand point, it shows that the creators want their products to be built upon. It allows for their creations to be replicated and made better and used in other aspects. Those who want this usually use sites such as Thingiverse.

Blog Number Six

The article Disruptions: On The Fast Track to Routine 3-D Printinggives a look into the future of 3D printing. The world has come along way with technology, but we are not to the point of the Jetsons as many thought we would in the new millennium, but 3D printing is rapidly advancing. 3D printers provide a large printing capacity, in that they can print metals, plastics and ceramics all in very customizable orientations. The 3D printing industry got a big promotion and applause from President Obama in his State of the Union address in January. He believes that this is a step in the right direction towards bringing manufacturing back into the United States. Not only does 3D printing have an affect on all industries but it is making its way into schools. Many school, grades K-12, are incorporating 3D printing into their curriculum. The Center for Technology and Teacher Education uses them in their classrooms in was such as building models and then analyzing the efficiency of the design. According Nick Bilton, the author, what makes this possible is the reduction in price. A few years ago these units were nearly $20,000 but can now be purchased in the neighborhood of $1,000. In London, within they year, they are planning to "print" a house. Although it might not be the most beautiful house on the street, what it comes down to for 3D printing, is with time, what won't they be able to print?

The State of the Union address was mentioned in this article because Obama discussed 3D printing. There is a government funded movement to create 3D printing "hubs". The the speech addresses the concept and what it can do in America. Obama makes it seem that he is at the helm of this endeavor, whether that is true or not is unclear, but Obama is aiming to bring manufacturing back to the United States. He is hoping that larger companies will follow suit. I think that it is important. This country was built on manufacturing. But these processes have long been outsourced to drive down costs. I think that it is time for manufacturing to again be a big part of the U.S. economy.

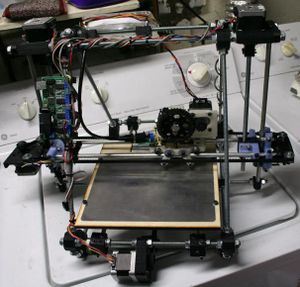

These printers are very different than ours. The printers at The University of Virginia are commercialized and very refined. Our Open Hybrid Mendel's are by no means commercialized, but we are able to refine them pretty well. Additionally, the article says that their 3D printers can print the dynamic systems fully assembled. The OHM printers that we use do not have that capability. I have no knowledge of the the ease of use of commercial 3D printers, but I feel that if we were to use our printers in the same manner it would work well. I feel that our printers are capable of that task. What it comes down to is time again. We are halfway through the semester and we are still working on fixing kinks in our printer and overcoming obstacles that we encounter while printing. For a dynamics class to jump in just start printing would not work on our machines, and I would think that it would be the same for commercial 3D printers.

Blog Number Seven

3D Pen

The 3D Pen Plotter is sweet. It is not precise like a 3D printer but it allows more flexibility. It is a hand held device that prints plastic in shapes drawn by the pen holder. It can be used to draw 3D objects free in the air, or given a pattern, it can trace the pattern and stick them together creating 3D objects. The ease of use is the big attraction here. It is a simple device that plugs into the wall, the plastic wire feeds into the back and a button extrudes the plastic through the hot tip. There are very few limitations to this device. Everything is limited mainly by the user’s ability.

Tangibot

The Tangibot is a MakerBot Replicator just refined and made cheaper. It was developed based off of the open source information regarding MakerBot. It is very accurate and well refined machine capable of quality prints. Tangibot offers savings of up to $700 when compared to MakerBots. The creator of Tangibot has an extensive background in electronics and has shown that his machines are reliable and accurate. He is looking to further refine the process and bring down the cost as development continues. Unfortunately he did not meet his funding goal and the project, on kickstarter, is at a standstill.

RoBo 3D Printer

The RoBo 3D Printer is another attempt at a mass produced open source 3D printer. They do a very good job of making it look aesthetically pleasing. Their cost for the product is very low when compared to MakerBots and the Tangibot. At $500 plus shipping, the RoBo 3D Printer is a steal. They boast a large printing platform, a printer capable of high detail, and it is open source. This helps their development. Changes can be made by anyone and then posted. RoBo 3D Printer can then take those changes and incorporate them into their next generation.

Form 1

The Form 1 3D printer is really cool. As advertised, it looks to produce very high resolution prints. They don’t actually mention a cost within the article as far as the purchase price goes, but they say that it will be much less than a conventional 3D. This is not an open source 3D printer so the costs will typically be a little higher. But the technology is phenomenal. This though, is where they are getting into trouble. 3D Systems has filed a suit against Formlab for knowingly infringing on a blanket patent for stereolithography and cross-sectional 3D printing. The technology that Formlab is using is very high tech, but apparently covered under a patent for the time being. If this can get sorted out, in favor of Formlab, I think that they have an excellent higher end product.

Printxel

The Printxel 3D printer has an awesome price of $300. It is a low cost machine capable of printing quality parts. The prints that are shown on Kickstarter seem very well done. The printing area is somewhat small, 5.5” x 5.5” but for the cost and quality the small print area can be overlooked. The design of the printer is unique to any others that I have seen thus far and seems to work well. I think that overall it will be a good printer.

The Vision

Based on the Prusa Mendel printers, The Vision is one user’s refined version. The creators didn’t stop at the “normal” specs. They have multiple models to fit the needs of the individual user. They offer a lot of options to customize your printer. From being made of plywood to lexan, they also offer different bed sizes up to 12.25” x 12.25” as well as the option for a dual extruder. There is no mention of cost for each specific model, but the $750 pledge level gets you the most basic printer.

I think that Kickstarter is a really cool and valuable tool. It gives those who do not have the means to back projects the opportunity to try and get those funds. I’m not sure that Kickstarter itself is the future of crowd-sourced fundraising but I think that it is a good representative of where it is heading. It allows people to see if funding is available but if the goal is not met, the investors owe no money.

Every business or website in the world has its problems, including Kickstarter. The article Who’s the Shop Steward on Your Kickstarter? highlights some of the “flaws” of the website. I use the term “flaws” loosely because I feel that they are just part of the business. Kickstarter is somebody’s business and they are looking for a profit just like each and every person who is putting ideas up to get funded. They have to pay the people who manage the money issues, and it is profit/income so you need to pay the taxes on the income. All of this comes out of the money you raised while reaching your goal. What it comes down to, is that if you need X amount of dollars, you need to set your goal at Y. Y includes the 10% that goes to Amazon and Kickstarter and then plan on the 15% income tax. They may not be forthcoming with these expenses at the beginning, but they are not trying to hide them. As an aspiring entrepreneur, you should know some of the ins and outs of the business world, and one of the key things to remember is that nothing is ever free. You should expect that there would be fees to be paid. While there are also countless hours of marketing to be put in to raise the money that you hope to, that too should be expected. If your idea is truly good, the marketing and advertising will take care of itself with minimal help. But if you really believe in something, it shouldn’t be that big of deal to have to push your product to friends and people you don’t know asking for support. If this is hard for you, you are in the wrong business.

When using Kickstarter you don’t have to front the money as you would if you went with a storefront. Kickstarter allows you to see if others think that you have a good idea and they show that by giving money to support your venture. With a storefront you need a large volume of money to start out. You need to pay for the store front, invest in the equipment and the overhead and you still don’t know if the company will go anywhere. If you manage to get an investor, the investor will want some cut of the profits as does Kickstarter. On the other hand though, having a storefront enables your customers to see exactly what you are offering. As opposed to pictures and videos, the customer can see and feel exactly what they are buying and ensuring that it is what they want. I don’t think that either option, Kickstarter or the actual storefront, will be going anywhere anytime soon. I think that they both have their advantages and allow for an entrepreneur to facilitate the selling of an object the way that best fits him.

Blog Number Eight

After reviewing the blogs #4 and #6 of my peers, who can all be found at Scrugmembers, I found Michael Bilyk’s, Chris Marcocci’s and David Long’s blog particularly insightful for Blog #4 and Michael Bilyk’s, Matt Rockar’s and Xiaomo Zhang’s blog insightful for Blog #6.

Blog Number 4 Review

Michael Bilyk does a very good job presenting his ideas within his blog. His thoughts are well organized and well thought out. Mike looks at the advantages of today’s communication methods and the fact that both parties involved had 3D printers which enabled the time for the design loop process to be cut down drastically. In the open-source vs. closed-source debate, Mike makes a strong case for keeping projects open sourced, hitting a lot of the major points. It is clear that he is for open-sourced projects by the lack of pro closed-source points, which is not a negative but merely an observation. Mike has some great ideas for ways in which we can get involved with the prosthetic hand project. In particular I like his idea for putting a chip in the hand with the build plans on it or a link to a site with progress on the design of the hand so that those using it have the ability to “upgrade” when they see that new ideas have been posted.

Chris Marcocci has good insight into the cost aspect of this project. One of his points is why invest in an expensive hand at such a young age, when surly he will outgrow the hand and a new one will need purchased? It is a valid point and he believes this is where 3D printing becomes involved, printing cheaper alternatives which can be easily altered as the child grows. Chris does an effective job at analyzing open-source vs. closed-source. He provides pros and cons for both positions and hits a lot of the key points. Chris’s idea for involvement on this project was on that I don’t think I saw from any other member. He thought a physics model, analyzing the stresses and strains of the hand and material would be a good thing to have. I agree with him, this would help the builders and users understand the limitations that the hand has from a mechanical standpoint.

David Long’s thought’s on the collaboration on open-source projects in this instance are very good. He says that sharing ideas with others leads to a better and more refined product. In the case of the robo hand it did. They weren’t looking for the monetary gain that may have come from this as large companies would have been and this helped drive down the cost. David’s idea of reaching out to somebody in the local community that may be in the same situation is a way that we can get involved. Print them a hand and troubleshoot our issues to make it better and to help the person out. I think that this is a very thoughtful idea.

Blog Number 6 Review

Michael Bilyk does a good job of conveying what the articles were talking about. He summarizes the first article very well although he doesn’t put much of his own thought into it. As far as 3D printing showing up in the State of the Union speech, Mike was spot on when he says that it will increase interest, and he goes on to say that interest, especially at Penn State, is paramount when it comes to our RepRap class. Mike’s analysis of the University of Virginia’s plan to incorporate 3D printing into their mechanical engineering program is great. He discusses the gains in having students able to visually see how the machines within the text book work, but at the same time he discusses the stumbling block of cost. When looking at our program, his two best points are the consistency of our printers and the little nuances that each has. When the same people and only those people work with a specific printer, it seems to work fine most of the time. It is when others move in to use the printer that we encounter problems. The program would require many different people to use the same printers and they most likely wouldn’t function the way that they were intended to.

Matt Rockar also does a good job summarizing the articles. His point on the State of the Union speech is very accurate. He says, “… it highlights how new this technology is and how much potential it has to revolutionizing so many things.” I think that this is absolutely true. Matt says that using 3D printers in education will help to excite students about science, technology, engineering and math is a really good point. It brings a hands on approach to these fields but he also points out the cost disadvantage of this component of the education process. He brings up cost again when comparing our printers to that of the University of Virginia stating that their printers are probably an order of magnitude more expansive than the ones that we use, but ours would have the capability of printing similarly to theirs. Additionally, a positive to our program is that we can reproduce printers while industrial 3D printers cannot.

Xiaomo Zhang’s insight is great. I think that Xiaomo’s thoughts are a little bit different than most in the class in terms of what points are made. Bringing 3D printers to every school in America is a great point that was concentrated on in this blog. The case is made that most students would not be able to troubleshoot the issues as well, but would be very capable of running a well functioning printer. It should be used as a way to keep the kids interested in these types of topics. The comparison of Penn State to UVA, in terms of what they are doing for 3D printing is something that I hadn’t looked at. They are both doing a great job of showing students the relevance of 3D printers in society. As in the other two blogs that I talked about, the price is one of the main points, in addition to that, Xiaomo brings up the student to machine ratio which is an interesting way to go about it. At UVA the ratio may be 20 or 30:1 while Penn State’s is more like 3:1. I thought that it was very interesting.

Although all of the blogs were good, I think that Chris Marcocci would get the extra XP for Blog Number 4. His open-source vs. close source analysis was good and I thought that his idea for involvement in the robo hand project was unique and out of the box. For Blog Number 6 I would give Michael Bilyk the extra XP. He makes great points regarding the State of the Union address and does an excellent job of comparing our program with that of UVA. His thoughts of how our printers might hold up if put in the same application that UVA is using commercial 3D printers is pretty spot on, I feel.

Blog Number Nine

This article, Autodesk announces ReCap: Creating 3D data from photos and scans, is really cool! Being able to input a scanned image into an Autodesk program and have it build a 3D model will be incredibly helpful. Because it is my field, I found the application to civil engineering especially interesting. Using this application to test feasibility of new roads, bridges as well as determine interference with the current location of underground utilities is ground breaking. This has the potential to do a lot of good, especially from an engineering standpoint.

The photo based models are done a little differently. Depending on the software, as little as two photos can be taken for some of the less precise versions, up to a number of photos from every angle. The more photos used allows for more accuracy in the model, but this depends on the software being used. Using pictures from multiple angles is done so that all sides of the object are covered. The photos are loaded into a photo based software and the computer interprets the photos and builds a 3D model based off of the information gathered from the pictures.

Here is a link to insight3d, an open source image based 3d modeling software. This one seems to be the best that I could find, it showed up on a lot of chats and seems to have a lot of options. Additionally, here is a forum called Superuser that gives links to a number of different sites that have photo based 3D modeling software.

Blog Number Ten

The Prompt:

Read everyone's Blog #8, these can be found Scrugmembers. If you were selected in others blogs as having a good one, note this. If no one wrote about your blogs, what might you do to make them more accessible? If your blog was 'highly rated', do your best to give guidance in how others might emulate you. Consider how you might organize your responses for maximum XP for the rest of the course.

My blogs were selected by more than half of the class as being one of the best or the best blogs. The biggest thing that I saw wrong with the blogs that others wrote was their lack of content. There were a lot of people who didn’t take the time to write a complete blog. They wrote four or five sentences just to get the assignment done, but didn’t do any of the research, some didn’t completely answer the prompts, while others were did answer the questions but were very brief. The best advice that I can give is to just put some time into writing the blog. They are very easy assignments that occasionally require a little bit of time commitment. Take the time to fully summarize the important points in the article and then give your personal opinion on the topics. Take a second to do a quick Google search on similar topics. Include some of the information to help make the blog more interesting and enjoyable for the reader. Add links to other similar topics or things related to the article. If people aren’t sure what you are referencing, a link is a great way to help expand their horizons. Another great way to spice up your blog is to add pictures. Pictures enhance your writing and make it more enjoyable for the reader. Depending on your choice of picture, it can clear ambiguity on topics that you are discussing.

To maximize the XP gained for my blog responses I will continue to use links and pictures within my blogs. These are great for helping the reader to understand the content. Additionally I will continue to take the time to research and compare similar topics and expand upon my answers. Being brief is good in some circumstances, but writing more and having the quality responses is better when responding to these blogs. Also including my personal opinion and personal knowledge within my blogs is a great way to maximize my XP potential.

Blog Number Eleven

Prompt: Given your experience with our OHM RepRap design, are there any parts in particular that you would redesign? How might we improve on what we have?

I think that one part that I would redesign is the Gregs_accessible_wades_v6 aka “extruder body.” Overall, the part works well except for the connection to the steel plate. On the front end, it is connected to the plate by only one bolt. The motor and the gears often torque this piece and with only one bolt, the printed layers tend to split from the rocking motion. Most of the printers us small pieces of wood to keep the plastic part from resting on the metal plate, often heated up by the extruder tip. The placement of this wood aids in the torqueing of the part. I think that the best way to improve this design is to simply add a second bolt through the end. The second bolt and washer will spread the stress from torqueing over two areas rather than one, thus decreasing the concentration. This will lead to a prolonged life as well as help to stabilize the entire extruder during the printing process.

Blog Number Twelve

The Prompt: "Our next big projects on the horizon are the dual extruder and the filament recycler. If you had to focus on one of those two projects, which one would you push and why? What are the relative merits and motivations behind choosing each? How does each advance the RepRap project more generally?"

When making any decision, it is best to look at what each option brings to the table. The dual extruder provides a few advantages over the typical single extruder. A single carriage now has the ability to print more than one color filament. It allows for more creativity from the user giving the ability to make more intricate parts. Another option for a dual extruder is to have different size tips on each extruder. We recently finished making .35 mm extrusion tips which are .15 mm smaller than the .5 mm tips that are currently on most of the extruders. .35 mm tips give more precision, accuracy and resolution, but it takes twice as long to print a part with the smaller as it does with the larger nozzle. By having a .35 mm tip and a .5 mm tip on one printer could allow for great resolution on perimeters while utilizing the bigger flow rate of plastic out larger nozzle for fill. The filament recycler really only has one purpose and that is to reuse filament that has been wasted. Every print that we perform has a perimeter around the bottom few layers of desired part. After the print is finished, the perimeter is simply thrown away. The filament recycler will allow for the perimeter, as well as any botched prints to be reformed into usable filament. Although both projects can have a significant impact on the future of the RepRap course, I feel that the filament recycler will provide the most benefit to the class. There is currently a large box of filament from prints that have been botched and small pieces of filament that are too short to print anything with. Filament is expensive so any wasted is money lost. The filament recycler will allow us to reuse all of the waste and help to decrease the running cost of this class.

Blog Number Thirteen

The Prompt: "Name one or more topics related to 3D printing which you wish we discussed in greater detail during the course. How might we evolve the course in the future?"

I am a Civil Engineer so I think that design and construction is important. In Blog Number Three, we watched a TEDx Talk by Behrokh Khoshnevis discussing the application of 3D printing in the Civil Engineering world. Through our blogs we did a great job touching on multiple fields where 3D printing is beginning to, or has already had an impact on society. I would have like to dive deeper into some of the issues, especially the 3D printing within Civil Engineering, and talked about them and how they are progressing. I like the fact that we covered a lot of topics, but I would have like to go in depth on at least one of the topics. I thought that the 3D printing of buildings was really creative and intuitive. If the whole process gets off the ground it has the ability to revolutionize the way that future construction is done.

The way that this class is run is unlike any other class here at Penn State. It is unique in that it is all pretty much hands on and allows for a lot of problem solving, trouble shooting and using an engineering thought process. One of the best ways that I can think to help evolve this class deals with the printers. Our group in particular had a lot of issues with our printers. We never had a week that we were able to just come in, start printing, and print through the entire class. We encountered problems every single class period. Rather than printing most days, we would spend the entire class period trying to fix the problems with our printers. Some of these issues were problems that everybody encountered on a semi normal basis. But there were a lot of issues that came because other people would use our printers. We would spend hours working out problems and tuning our printer to where it was finally able to print quality parts. Others in the class would hear that it printed well and would use it during non-class hours to complete prints. But somehow, it seemed that when we came back to class, the printer would never be printing with the same quality that we left it the class period before, or even capable of printing at all sometimes. It is incredibly frustrating to have to continually fix our printers class after class. I think that setting limits on using other printers is necessary. I feel that had we had a not had to spend countless classes always fixing our printer, we would have better been able to evolve aspects of the class. I know that every group had issues with their printers, but I feel that anytime we got close to having a printer that worked well, we would get set back due to it being used by others. By limiting who can use each printer, we can learn the quarks of the printer and understand how it runs, as opposed to letting those who have never printed with it before fire it up and potentially mess up the configuration. Eliminating as much frustration as possible will help evolve the class.

Projects

Open Hybrid Mendel Construction

Dual Extruder Construction

Bonus Blogs: 3D Printing In Society

War Against Magazine Capacity

There has always been an issue with gun control in America. The issue, in the more recent past, has been a huge topic from a political standpoint. The Republicans and Democrats have very different views on the Second Amendment. Gun control was a big issue, for Americans, in the presidential race between John McCain and Barack Obama. The uproar on the issue died down some number of months later, but was brought to light again after the Sandy Hook Elementary shooting on December 14, 2012. The major issue now is magazine capacity of all weapons, with the primary focus on assault weapons. It is the feel of most Democrats that the number of rounds a magazine can hold should be limited. Currently, the typical magazine capacity for an "assault style" weapon such as the AR-15 is 30 rounds, but can vary state to state. Politicians are not trying decrease the capacity to a possible maximum of 10 rounds. This is a very touchy topic for some people, and there are those who don't understand why one might want a magazine to hold that many rounds. I'm not here to make a case or give my opinion (although it may not be hard to figure out), but to share the way that one group of people is looking at this issue. The issue is that the government is looking at banning the sale of magazines with a capacity over a certain amount. One group is looking to 3D printers to "solve" the issue of government intervention. In the article, Print and fire: 3D printing could muzzle new gun laws, a group has open-sourced a file that allows those with a 3D printer to be able to print 30 round magazines. I am not sure where the legality of this will fall when all is said and done, but they are not being sold but rather created. No matter what your stance on the issue, I think that this is cool and innovative. It is really neat to see the expansions of fields that now able to incorporate 3D printing into a "manufacturing process" that allows those with 3D printers to build their own products rather than buy them.

Promotion By The President

Coming at a later date...... Obama's speech highlights rise of 3-D printing