VertX

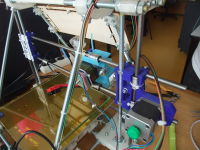

Release status: working

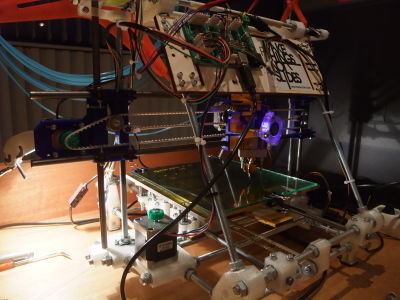

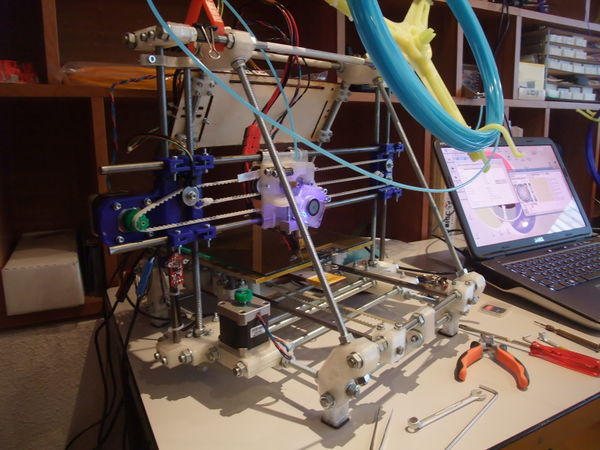

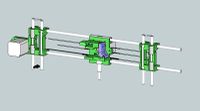

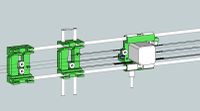

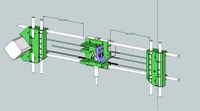

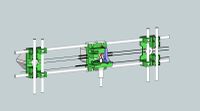

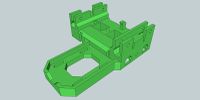

| Description | an integrated x-carriage/direct-drive-extruder, and a whole vertical x-axis mod for the Mendel

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | Development

|

| CAD Models | |

| External Link |

Contents

Benefits

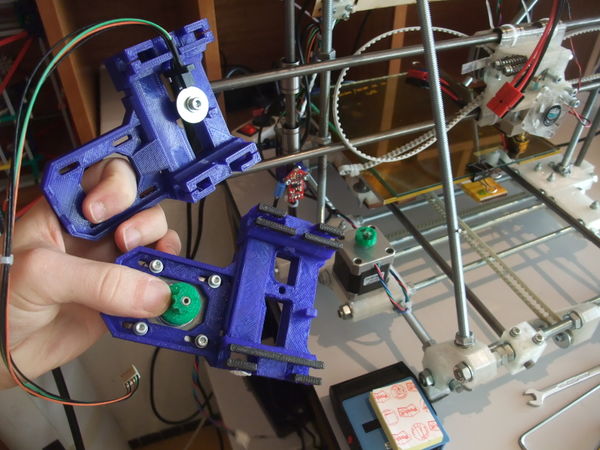

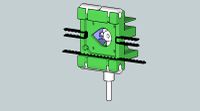

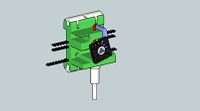

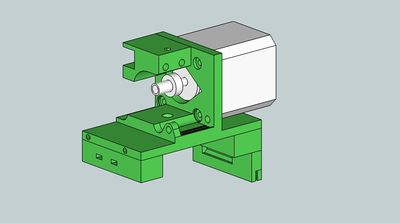

- a very compact (74mm wide x 42mm deep x 83mm tall) and accessible extruder, made of only 2 pieces.

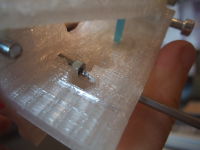

- with LM8UU, zip-tie locked, and which bearing holders tend less to snap, thanks to the printing orientation

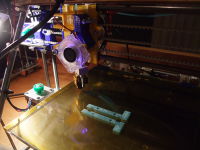

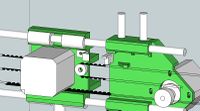

- active cooling with a little fan (or two), mounted on only one point : just rotate if you need to access behind

- integrated (but optional) Double pulley driven x-axis (inspired from the Madkit's double resolution mod), that don't bend the belt backward

- the whole x-axis may be assembled without removing any Z-rods (except to put linear-bearings or nuts on it)

- the x-carriage can move over a distance of 250mm (230mm with the belt loops)

Resulting print volume : 220 x 187 x 94mm

Weakness of the actual version

- By off-centering the hotend, the y-travel is a little reduced (-18mm).

- The top board (on which the electronic is) need to be mounted on the back, or the fan in front of the x-carriage will touch at maybe Z-60.

- Finally I wouldn't recommend the double pulley system, it's a trade-off between precision/speed, and we don't need that much precision, while the motor's speed will reach it's limit at 150mm/s travel (with a Gen6, at 40-step-per-mm base and 80 with the double pulley)

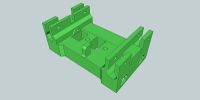

Sells/Prusa Mendel

If you upgrade from a classic Sells Mendel, you already have a long belt and most if any of the vitamins required.

| Item (and approximate weight/time | Vitamins | Item (and approximate weight/time | Vitamins |

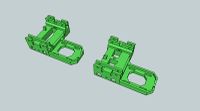

x-carriage  ~30gr/80min |

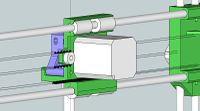

4 LM8UU 4 M3x8 (motor) (1 M3x10 for the optoflag) 1 M4x20 (fan) 2 M4x55 (+ 2springs) 2 624bearing (and 2 M4x16-20 + 2-4 M4 mudgard washer) |

x-end-motor ~40gr/90min |

2 M8 nuts and 2 LM8UU 4 M3x10 (motor) 2-4 M3x15 (clamping the smooth rods) 1 624bearing + 1 M4x30 + 2 M4 mudgard washer 1 M3x8 (opto-endstop) |

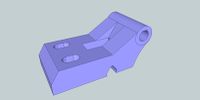

x-carriage-idler  ~4gr/10min |

1 624bearing + 1 M4x20 (to hold the bearing in the idler) 1 M4x40 (axis) |

x-end-idler ~30gr/60min |

2 M8 nuts and 2 LM8UU 2-4 M3x15 (clamping the smooth rods) 2 624bearing + 2 M4x30 + 2 M4 mudgard washer 1 M3x8 (opto-flag) |

z-rod-stabilizer  or thing:9864 ~xgr/xxmin |

2 608 bearing + 2 M4x20 | printed opto-flags 200px ~xgr/xmin |

(seems to work when printed in black) M3 nuts |

| Total : ~100gr. and ~4h | Add some zip-tie and as many washers/nuts as needed |

Don't forget to change your firmware :

- calibration for the direct drive (e.g: 325.57 -> 77)

- invert the extruder direction (e.g: in Marlin #define invert e-dir false -> true)

- and double the X-Step_mm (e.g: 40 -> 80)

How to assemble it ?

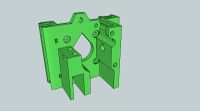

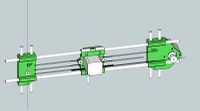

X-end-motor

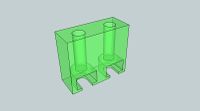

X-end-idler

Same as precedent but simpler (without motor/endstop, but with an additional bearing)

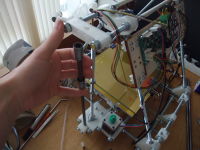

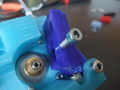

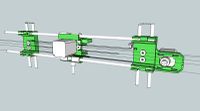

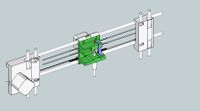

X-carriage

picture of a nice exploded view ala Ikea

Idler:

X-Carriage-Extruder:

Note : the "double resolution mod" is optional, you can also use a shorter belt with the same parts just by removing a bearing on the x-ends and hooking the belt loops at the x-carriage instead of the x-ends.

R&D

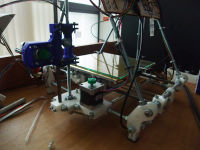

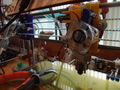

VertX 0.8.1

<videoflash>H24Jyxte9Ak</videoflash>

(I'm not using any more the double pulley trick)

- x-end-motor v10

- stiffer

- little hole added to hold the magnet for a Z Hall-O endstop using that holder : http://www.thingiverse.com/thing:15769

- enlarged clamp to prevent breaking

- x-end-idler v11

- enlarged clamp to prevent breaking

- V0.8.1

- V0.8.0 : x-carriage v12 , x-end-idler v9 , x-end-motor v8

First print !! --Emmanuel 17:04, 10 November 2011 (UTC)

- Adjustable-z-opto-mount

- VertX 0.7.3

<videoflash>6sF87FcMKyI</videoflash> <videoflash>A2Ip-SDKsBQ</videoflash> <videoflash>6Hr-rmyoSp0</videoflash> <videoflash>PtAVdr6idRY</videoflash> <videoflash>zQ1FfjxCEE0</videoflash>

- Extruding/filament swapping

- Motor move, front and rear

- Manual move : smooth ! : http://www.youtube.com/watch?v=gwKG6C917AE

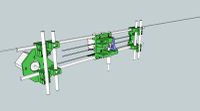

- VertX for hotends with mounting points (for the v6 in my case)

- X-carriage and idler

- X-end-motor

- X-end-idler

- 70mm between x-rods and minors improvements

- In order to center the motor instead of the hotend I had to invert the x-end-motor orientation and thus we are back to the two motor on the same side, but maybe the mass will not be such a problem (or compensated by the centered extruder)

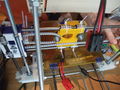

- VertX 0.7

- As expected in a "double-resolution" configuration it only make half of the distance with the old E Step MM and we must double it in the firmware.

- It move ! more pictures/videos on flickr : http://www.flickr.com/photos/watsdesign/6093138294/in/photostream

- Vertical Axis V0.6

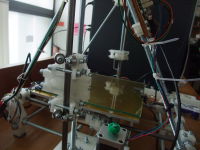

- First assembly

manu_x-carriage_pushspring optional, for comfort to push on the two springs (hmm finally it feel better without))

- X-ends v6

- X-end-idler v5 : Only ~30gr (15gr saved from the v2) and ~45min to print (at 40-120mm/s with Marlin)

- Axis v0.5 : A LOT of modification were made (quite time consuming)... but it's on its way ! (some more pics on flickr)

- X-end-idler v2 : 33mm between the rods was finally too much, it seems to be ~28mm

- X-carriage v2

Inspiration

- EMAKER_Huxley

- Huxley-eg

- The Gen X Skb-Kiparis remix I discovered on this thread : http://forums.reprap.org/read.php?94,84403,93044#msg-93044

- Orca and the v9

- And all the existing reprap stuff that certainly influenced me

I wanted to design a vertical carriage with linear bearings, but mixed with the ideas behind the V9 (direct drive, no damn PTFE, no mouting block) to make it even simpler. And thus came this "carriage-struder".

Orca (70mm between x-rods)

There is better on thingiverse now :)