TitaniumAlloy

Proposed development

Printing with easy to mix Titanium alloys on Mendel printer

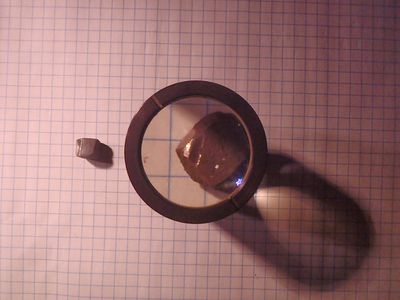

Samples alloy metal parts made from paste:

Extruder: can be the ParametricSyringeExtruder - but it will be beneficiary to design extruder printable from the same alloys.

Solidification: Air. Vacuum chamber: heat - from 100C - 820C step +5C/min, 25min under 820C, then holding vacuum, drop temperature to 350C, and release vacuum valve.

Paste mixed with metal powder in proportion usual for powder metallurgy (any mix suitable), then after mixing done, add PVA with the water. Viscosity is high for sure and require pressure to extrude, but after solidification (air/heating), model is solid to be placed into the vacuum oven. Metals like Aluminum will be require carbon powder to add. Starсh - working but solidification is not good. Mineral oil - not working. Best results are under PVA.

Project home page adobri web site