TitaniumAlloy

Proposed development

Printing with easy to mix titanium alloys on Mendel printer

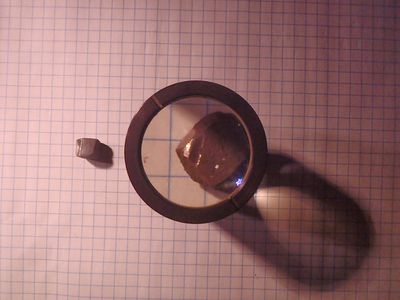

Samples of parts, made from the paste:

Extruder: can be the ParametricSyringeExtruder - but it will be beneficiary to design extruder printable from the same alloys.

Solidification: Air. Vacuum chamber: heat - from 100C - 820C step +5C/min, 25min under 820C, then holding vacuum, drop temperature to 350C, and release vacuum valve.

Paste mixed with metal powder in proportion usual for powder metallurgy (any mix suitable), then after mixing done, add PVA with the water. Viscosity is high for sure and require pressure to extrude, but after solidification (air/heating), model is solid to be placed into the vacuum oven. Metals like Aluminum will be require carbon powder to add. Starсh - working but solidification is not good. Mineral oil - not working. Best results are under PVA.

Project home page adobri web site

Proposed extruder

Existing paste extruders has that limitations:

- Material for printing limited by a syringe size (10-20 -200 cm^3)

- It is hard to make the small diameter extrusion - viscosity is high.

Probably needs to make the screw extruder. Dry powder is delivered by vibration via the plastic tube (thus less inertia parts for positioning mechanism). Once debugged using dry powder, so through the central part (with ball valve) delivers pressurized water with PVA - water. Ratio liquid / powder adjusted by (a) turning speed of the screw, and (b)the water's pressure. Small 100$ desktop compressor with an automatic pressure control will be preferable.

For the beginning the mold 3D printed from the plastic (for extruder) can be made. Then next step will be to 3D print the extruder itself.

Design with two extruders can allow combining two metals with different heat conductivity and strength.

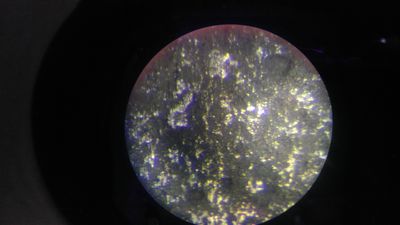

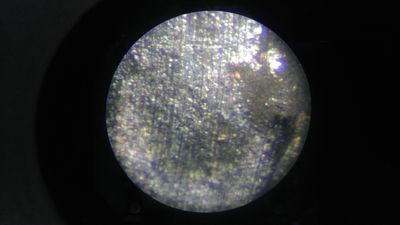

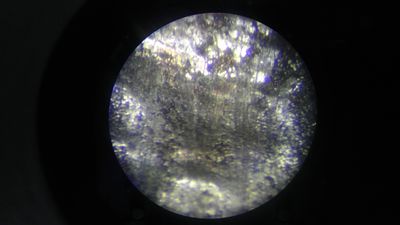

With the composition of PVA and water the attempt was just lucky - 1 part of PVA to 4 parts of the water is the best mixture. In experiments with different proportions got outcome with more cavities. Pictures from microscope of the alloys-

That has cavities - mostly because of low silver. Probably with 20-25% it could be solid, more heavy and strong. Longer time in oven (around 820C) can help to reduce patches of not solidified grains.

That is perfect sample - strongest and solid practically without cavities.

That is 2000 years old technology - solid, strong, and non expensive (0.5-0.8 cents per cm^3). Probably that can bring bronze age back to houses.

And needs to find the (easy) way to measure all mechanical parameters of alloys.