User:Atokarz

Contents

Introduction

Hello! My name is Austin Tokarz and I am a senior undergrad student at The Pennsylvania State University. I am majoring in Mechanical engineering. I am also in the Navy ROTC program at Penn State and will commission as an Officer when I graduate in May of 2014.

I'm currently working on the Gold printer with Ian and Patrick.

Blog Number One

Various Printable Objects

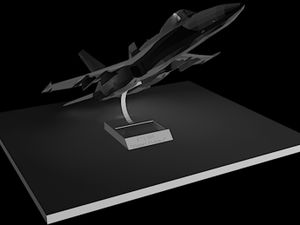

Something that is amazing/beautiful

I am very interested in the aerospace community, so this model caught my eye. It is a model of a F/A 18, but more than that, to me it shows that aerospace companies could easily print out scale models, such as this, to test in their wind tunnels, etc. So, that is amazing to me. The item can be downloaded here.

Something that is funny/strange

Something that is Useless

Something that is Useful

I frequently use a camelback hydration source when I hike and the hose of the water container is impossible to control. This item is amazing. It allows you to clip the hose to the strap and easily secure it. The item can be downloaded here.

The Best Raspberry Pi case

So whats better than a Raspberry Pi case that you can print yourself? How about a Raspberry Pi case that you can attach to a belt and take with you whereever you want. The item can be downloaded here.

Blog 2

Something class related that interests us

Now that we have two weeks of class and print training under our belts, we can start to look at possible projects and topics to cover. I am most interested in the construction aspects of 3d printing, because I think that keeping cost and ease of construction low will help bring 3d printing to the masses. Aside from that I also enjoy working with my hands and I feel like I have a better understanding of something if I build it myself. Some possible topics that I think would be interesting to discuss in class include: how to make 3d printing more accessible to more people, aerospace/military applications and manufacturing applications.

Blog 3

Discussing Other Students' Posts

This week I will be highlighting a couple of the blog posts that seem exceptional to me as well as one or two that could use a little constructive critisism.

Best Posts

The first reason that I chose Abbey's page as one of the best is because the layout of it is extremely clean and orginized. Overall the page is the best that I could find. I really like the three-page tabs on the top. That being said, I also really enjoyed reading her Blog #2. The internship in France must have been and amazing experience and I too am interested in the 3-D scanning technology. I think that if someone could bring in a XBOX Kinnect and we could somehow set that up that would be awesome.

I chose Ian's second blog post as one of the best posts in the class, because it was extremely well written and I could tell it's a topic that he is very passionate about. That sounds like a very interesting project and I would love to see it done. Not only could we save money by recycling everyday products, we would be helping out mother nature.

Posts that could use some help

I have to comment on Pat's blog for a few reasons. First: I think that it looks much better with the thumbnail images on the page. Second: you need to complete the week 2 blog.

Again, as I stated earlier, I just think that it looks much better with the thumbnail images, so get those in and the page would look great!

Blog 4

Comment on the video that can be found here

Most business models are based around the concept of selling goods. The makers of Arduino talked about how their business model is different. They first explained how money does not perfectly translate into wealth. They are separate. There was a farming analogy that basically claimed that a farmer and business man have equivalent wealth, but different cash flow, due to the farmers accumulation of crops. The Arduino business model is based on the premise of giving away "free" software and making money on the side. Similar companies include: google, linux and mozilla. The speakers then went on to proclaim that reprap's should have the same business model. Free software, but the companies can still make money on the side. This seems like a good idea to me. I think that it would take away from the 3-d printing industry if the open-source aspect was taken away.

Blog 5

Analyzing Copyrights and Trademarks within 3D Printing

A.

Analyze the selctions from Blog 1 and determine if any of them qualify as patentable or copyrightable.

F/A 18 Model: This print could be considered patented. Patents cover technical works and I would venture to guess that the engineers at Lockheed have patented the body design (along with pleanty of other things) for the aircraft.

Statue of Liberty:

I'm a little wishy-washy on this one. Obviosuly it is a landmark and a symbol of America, but that being said I have no idea whether or not it would be IP. Part of me says no, because I dont know who it would belong to. Possibly the original French designer. But part of me thinks that America has a grasp on it and makes it impossible to reproduce. If it would be anything, it would be trademark infringement.

Shoe Bow Ties:

I'm pretty darn sure that anyone can produce a bowtie design, so long as it isn't a part of someone's logo/company design.

Camelback clip:

This one is trademark infringement. The reason is that it claims to be a "camelback" piece. Without their permission, they can't make that claim.

B.

Analyze your classmates items.

Scott has two items of interest. First is the Eiffel Tower, which falls under the same principles as the Statue of Liberty, which could mean it has a trademark violation. The second, similar to the Camelback system is the K-Cup holder. In order to call it a "K-Cup" Holder it has to be registered with the company so that is a copy right infringement.

C.

Legally, Licensing Non-Copyrightable objects has an interest to me, because it sets the boundary of giving a person a undeniable conditions on the object. What I mean by that is that the object's license is on paper. It's registered and in the system, so there's less grey area so there will be less debates and law suits over IP. Culturally, it is very good, because it retains some of the open-source aspects by attaching a creative commons license. This allows for the publisher to continue allowing other people to creativly expand upon his or her work.

Blog 6

One thing that I didn't comment on last blog was how the author came off as naive because what he put in his article. Dimitar does a really good job of pointing out two major aspects of the article that contradict the content of the article itself. Two points that I didn't pick up that Dimitar did are first that the photo used for the article is a copyrighted photo and second that the author never mentioned that the copyright triangle actually is copyrighted and belongs to Ulrich Schwanitz.

Blog 7

After reading the article titled: "how to build a for using 3d printing" I will explain a few hopefull things about the article and a few things about the article that's just hype. The first thing that made me hopefull about this article is the fact that this could interest children to become familiar with 3d printing and educate them on how it works by relating it to something that they enjoy doing. I think if the younger generation become familiar with 3d printing at a young age, then it could do big things for 3d printing. That being said, there are a few things about this article that remains hype. For instance, this all falls back to the copy right, trademark issues. All it will take is for one company to try to copyright a design for the open source nature of this project to be ruined. That being said, I think that this is a great project that will get the younger generation involved in 3d printing.

Blog 8

3d printing, unbeknownst to many, can help facilitate, cheap, reliable and flexible research. Virginia Tech has a laboratory named the DREAM lab that is used for that purpose. Their website can be found here. Such labs are crucial to maintaining the forefront of applied research.

A. 'Do any of the projects from ARMI stand out to you?' The article that interested me the most was the "maker juice" project. Initially I thought this project was really cool because the products printed were really intrinsic and beautiful. I then realized that there is a much, much larger application for the technology, which is printing organs. Also, the layer height was only 100 micron. That's crazy. I think similarly here, since we are a large agriculture school, we could use similar methods to look at printing food.

B 'Adjectives to describe what we do in class' -Team working -Hands-on learning -abstract thinking -creating

C 'Word that can describe what we do here' OSCAR: Open Source Creation And Research

Blog 9

Link One: The OS Water Boiler. Essentially in the end of the page, which describes an OS water boiler, there are photos of the difference between making 1, 10, 100 and 1000. The difference being that generally the material costs will decrese after a certain point and that the labor intensiveness will also decrease. From an manufacturing point of view, the more units produced, the less the labor intensive each unit is and the lower the material costs. Essentially, the more units outputted, means that the units can also be produced quicker.

Link 2: the OS kitchen. Link two is about a design for a coffee ginder that can be made and repaired by the user. In theory this is a really good idea because it means that you should never have to buy another grinder because you built it so you can repair it. It also seems fairly simple to create. In my opinion I don't see this catching on. Don't get me wrong, I would buy this product, but as a whole, I think people would rather just buy a grinder from the store, because the money spent on a new one is less valuble then the time to build one. I think thinks like lamps could also be produced in this fashion.

Blog 10

Discuss Jeff Immelt and Terry Guo's thoughts on 3d printing

Jeff Immelt

Mr. Immelt is currently an American business man and has held positions such as the CEO of General Electric and is currently the chairperson of the President's Council on Jobs and Competitiveness. Immelt is also a supporter of additive manufacturing. He is on record saying: “We make a turbine blade that is made of some of the most expensive high-heat material in the world,”...“We put that blade through the fabrication process and the excess material is essentially waste" according to wallstcheatsheet.com. Since he is the CEO of GE, he has said that such a big company should strive to own all of their manufacturing and he achnowleges that 3-d printing would cut down on costs.

Terry Guo

Mr. Guo is the founder and chairman of Foxconn; a company that makes electronics for large companies, such as Apple. Quite contrary to Mr. Immelt, Guo said that 3-d printing is just a gimmick rather than a game-changer. He said that he would be surprised if additive manufacturing lead to a third industrial revolution.

I think that the reason that Terry Guo has a negetive view on 3d printing is because he makes specialized parts. If you're making computer chips, there are pleanty of different materials in a part and its on a small scale. There are also likely humans who assemble them. So, he likely doubts that a printer could make such an intricite part. Jeff Immelt on the other hand, is talking about making a, one material, gas turbine blade. I think that he is more optomistic that it is possible.

Blog 11

Discuss aspects of printers that make printing difficult

Now that I have some printing experience, I can talk about aspects of printing that are frustrating. In order to do so I will recall two different instances that I encountered while printing. The first was with Beta. I was about to print and I got a cold extrude prevention warning. It turned out that one of the wires to the hot tip came undone, so I had to take it out and reattach it. The second instance was with the purple printer. I sat down and the monitor was blank. I unplugged the pi and reset it and it worked. Then I tried to edit the gcode and the keyboard didnt work. After recruiting some help, we ended up swapping out monitors and got it to print. So, the things that have frustrated me have been involved with wiring and the equipment (monitor). Also, I have had to swap out a gear on beta and fiddle with the belts, so mechanically little things have been frustrating. I think regular maintenance could combat that.

Extra Blog 1

Manufacturing with 3d printing

One of the aspects of 3d printing that interest me most is manufacturing. After reading the article that was about Terry Guo's thoughts on 3d printing, I basically concluded that I dissagree with everything he has to say. I do think that 3d printing will cause an industrial revolution. Maybe not in our lifetime, but eventually it will. I think that he said the things he did because he works with specialized parts that must be handmade, but that is not even a conventional manufacturing way. I think that 3d printing will replace the conventional assembly line and subtractive manufacturing. I took a class on manufacturing processes and so much material goes to waste. 3d printing can use less material and save companies money. I can't speak much on the time it takes to traditionally make a part vs 3d print, but I would imagine that 3d printing could evolve to take less time. Also, there would be less need for labor, so companies wouldnt have to pay workers and that means that more companies could set up plants in America instead of paying Malaysian kids pennies for labor. That would also cut down shipping costs. Overall, I do think that 3d printing will revolutionize the manufacturing process and should be looked into by more companies.

Blog 12

What are the strengths of a platform like OpenScad? What are the weaknesses and limitations? Would you ever be tempted to use it, or the process of turning images into models shown above? If so, for what?

After reading the following links on OpenSCAD: [1] and [2], I have gained a better understanding of what the program can do and how it works. There are many strengths with a program like OpenSCAD, such as: it's great for coders. People who know a language, but never used SolidWorks would find the transition very smooth. Also, with the program, there are no limits to what can be made. If the user is skilled he can make anything. There are also many drawbacks. For example, if the user wants to change one thing, they need to change multiple parts of the code. That could get annoying over time. That being said, I think that I have enough experience with solid works and enough head aches with MATLAB to turn me off to a similar program. I think that the image to model aspect is useful though and I would be interested in using that.

Blog 13

Why would we want to incorporate this into our printing? What capabilities would this give us. If we could print conductive pathways into objects, what would you try to make with it? How might we try to make it work with the printers we use?

This week's blog was to watch a video that essentially showcased a new conductive ink. We could incorporate that technology into our inks, so that we could print a conductive object. This could give us the opportunity to make some really cool looking objects. By that I mean, we could incorporate LED's and lights into designs. That would look bitchin'. Also, we would have the capability to make electronic components. For aesthetic purposes, I would make a little model car with LED head lights. For a more serious note, I would try to make some sort of rudimentary circuit board. I think that the dual extruder printer would benefit most from this technology. A full object made out of the conductive material would be redundant, but if you could make a part of the object conductive it could be extremely useful. So, we could make it work with the duel extruder printer.