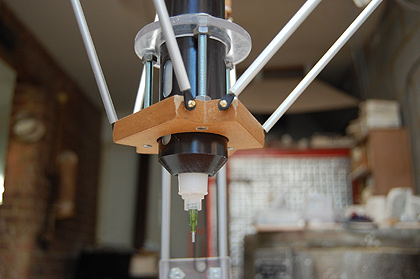

Ceramic delta

Ceramic delta

Release status: working

| Description | This is a delta 3D printer designed specifically for printing in clay and to be built with basic DIY skills.

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Ceramic delta is a 3D printer built in 2013 by JKeep in Suffolk, UK.

Contents

Design Goals

- To build a printer specifically for printing with clay.

- To keep it simple so other artists, designers and potters could build it.

- That all parts could be made with basic DIY skills or ordered of the internet.

- That it was made of easily accessible materials and you would not need printed plastic part.

- A print area of 20x20x25 cm.

Parts

The full BOM is in my Studio Journal on my website.

Build

The build documentation is also in my Studio Journal. Note: The accompanying PDF parts templates where sketched out in Microsoft Word so are not very accurate but are printable on a standard A4 printer and gives a basic cutting pattern that I have altered as I have gone along.