Gas nozzle hot end

Release status: working

| Description | Tutorial to prepare an hot end using some commercial gas nozzles

|

| License | GPL

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

NB: The following tutorial need the use of power tools (drill press) in some non-standard way. There will also be dangerous metallic dust filling the room. Also the tools and parts you are machining can easily break, projecting pieces of all dimensions and at high speed. Please wear heavy gloves, anti-dust mask and goggles at all time when using the tools. Some noise protection will be good too. I know it's not comfortable working in that way, but you really don't want to loose a finger or an eye, or breathing some aluminium and brass, just to make an hot end.

Gas nozzles come in many different shapes but they all have 1 thing in common: they are really cheap. I paid 6€ for a set of 5. After looking to various models I found the better suited are the "gpl nozzles", with 8mm screw and round body. The inside diameter is 5mm. Don't take the methane nozzles because they have bigger holes. With the smallest gpl nozzle the PLA filament I get is something between 0.45 and 0.5 mm which for me is more than satisfying.

My suggestion is to test all the machining first with the biggest hole nozzle, so any error in the process won't damage the little hole one, which is the most useful.

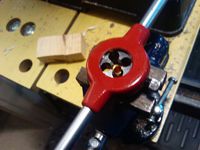

To be able to connect the nozzle to the other parts of our hot end we must use the die tool. The screw thread already present on the nozzle is not compatible with usual m8 bolts and nuts, so all become easier if we remake the thread. I used a die of size 8mm x 1.25.

Now we want to make the thread on the long side of the nozzle, to be able to mount the heater on it. We start by reducing the external diameter from 10mm to little more than 8mm.

I didn't want to damage the thread mounting the nozzle directly on the drill press, so I used an m8 bolt with cut head and a long nut. Use a cheap metal file (I bought a set of 6 for less than 5€). Be careful not to damage the hexagonal part of the nozzle, it is very useful!

NB:I made the photo with the drill press turned off. Remember: Never wear gloves while operating spinning machinery, wrapping a glove into the chuck of a drill press is a surefire way to break fingers!

Now using the same die tool used before we make a thread on the other part of the nozzle. Use a bit of oil so you don't damage the tool and go slowly.

This is the threaded nozzle:

The internal diameter of the nozzle is 5 mm, which is a bit too much for our needs. From my tests the nozzle would contain too much melted PLA and would be nearly impossible to stop the extrusion.. It works, but not very well. So I decided to reduce the diameter. I cut a 15x15mm piece of a sheet of 0.5mm aluminium, rolled it around a 4mm drill bit, inserted it in the nozzle and cut the exceeding part, leaving just a bit as you can see in the photo.

Probably a little tube of PTFE would be even better, maybe put your experience in this page if you want to try it.

The remaining parts are mostly like the standard nozzles. I drilled a cylinder of PTFE with a 3.5mm drill bit, and the last 5 mm drilled with a 6.5 mm drill bit.

Then I made an 8mm thread with an 8mm tap in the bigger hole.

This is quite cosmetic because the PTFE is too soft when heated and it will leak. My solution was to make a little aluminium collar, height 5mm, to place around the PTFE in the point where the nozzle screw is.. uhm.. screwed. Don't make it too big because the aluminium will accumulate heat and we don't want to propagate additional heat over the PTFE channel.

(..to be continued, just guess for now)