Gaseous pollutant filtration

Contents

Fumes and gases emissions

Printers emit pollutants

Printers emit toxic fumes,VOC and ultra-fine particles. [1] [2][3] [4] [5] [6] [7]

Also, if using cheap filament, they may emit heavy metals fumes.

Odors are mostly due to specific VOC components but it is important to note that many toxic components have absolutely no odor.

VOC and ultra-fine particles can be filtered.

If you want to build your own filter, filtering odors and VOC is easily done with activated carbon filters as found in kitchen filters. Filtering ultra-fine particles could be done with HEPA filters like those on vacuum cleaners, but pressure drop of HEPA filters is higher than Activated carbon filters.

There is no effective way to remove heavy metals. It is better to source filament from reputable suppliers in the US and European Union.

Filtering the VOC

The VOC are efficiently stopped by adsorption on activated carbon based filters. You found this kind of filters in Kitchen filters, vacuum cleaners and organic filters for respiratory masks.

Filtering the ultra fine particles

These particles (lower than 0.1 microns) are completely invisible, even in a laser beam and are undetectable without specialised equipment. They could be filtered with HEPA filters (they filter 99,7% of 0.3micron particles) or ULPA filters (they filter 99,999% of 0.1micron particles) [8]. Filtering these low size particles works by adsorption. You could find such filters in some specific vacuum cleaners or in respiratory masks cartridges. The efficiency of these filters improve with time, as the filtration 'clogging' improve the filtering media.[9]

Others non filtration techniques removal are based upon high voltage devices.

Activated carbon

Activated carbon is calcinated organic compound, and the activation [10] increases the holes quantity to have larger surface area. The surface is huge and could be from 1 to 500 m2 par gram. This is universally used to remove components in gases or liquids. Components are attracted on the carbon media by weak Van der Waals forces in a physical phenomenon called adsorption.

It is used as powder, granulates, beads or compounded on mattress for easier handling. It is often elaborated with charcoal but could be done with other organic matter (e.g. coal or oil).

How to get rid of toxic fumes

Exhaust fumes outdoor

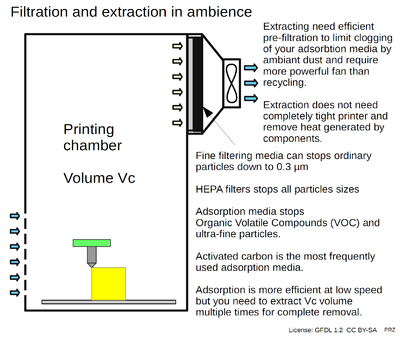

It is fairly simple to exhaust fumes from a printer with a computer fan. However, one of the interest of an enclosed printer is to maintain a warm temperature to improve printing and exhausting all fumes will cool the printer ambiance, and in such case you will need a recycling unit. The outlet of the duct could be sent to a filtration unit or outside the building. Another point is that in case of fire, the air inlet will supply oxygen to the fire.

Build your own filter/scrubber

Some have built filters while using commonly available components :

- Filter for respiratory mask [11]

- Filter for vacuum cleaner ('HEPA' filter)

- Bulk activated charcoal beads/granulates

- Activated carbon mattresses for kitchen air extractor

HEPA filters have high pressure drop and needs relatively high pressure fans. Systems using activated carbon media have a relatively low pressure drop.

Simple odor removal system have also been built with charcoal filters mattress for kitchen filters as they have a very low pressure drop. Charcoal is also adsorbing most materials and particles, so it may be the simplest overall solution.

A dust pre-filtration may limit the clogging of HEPA and activated carbon filters.

Even if not all toxics have an odor, smell removal may however indicate that a filter is efficient at VOC removal.

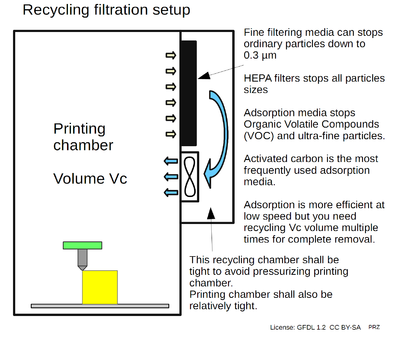

Without scientific details data, it is difficult to determine dimensions but from experimentations as described in forums and existing commercial filtration units (see links), a guess of what could be installed for a recycling unit of a printer is:

- Activated carbon filter of 250cm2 area, thickness 2cm (total volume 500 cm3 ~ 30.5 cubic inch). Same filtering volume with larger area may be more efficient, as lower speed improve efficiency. Media volume may not vary with printer dimensions, but area may be increased in order to maintain low speed with higher flowrate.

- The flowrate shall be minimized to have good overall removal efficiency (the principle is adsorption, not filtration), but you need sufficient volume renewal in your printer to open it. One volume renewed in 2~5 min may be a base. Printer doors may better stay closed during 5 recycling volumes.

Safety

Tight box

A recycling filtration system need to be tight. This means that in case of internal fire, there will be quick oxygen depletion and the fire will stop naturally. This is much safer than any other system and is recommended.

Non combustible walls.

You shall use fire-retardant panels, like melaminated chip panels. In case of fire, the burning of [|melamine] will produce nitrogen which will tend to stop the fire or prevent if to attain the wood part.

Using an ambient particle removal unit

It does exist filters to clean the ambient air, which may be installed aside the printer.

Already made printer enclosure or scrubber units

It does exist on the commercial market filtering enclosures or filtering block which could be adapted to your own enclosure.[12][13]

Filtering cartridges on commercial printers

An example of simple cartridge exchange on a commercial printer, which also gives idea about dimensions. Yet only a few commercial printers incorporate Filters: The Cubicon 'single', the Cubicon 'style', the Up!Box and all Cartesio machines (3 stages filter unit).

References

- ↑ http://www.sciencedirect.com/science/article/pii/S1352231013005086 Ultrafine particle emissions from desktop 3D printers

- ↑ http://pubs.acs.org/doi/pdf/10.1021/acs.est.5b04983 Emissions of Ultrafine Particles and Volatile Organic Compounds from commercially available desktop three-dimensional printers with multiple filaments

- ↑ http://www.3dsafety.org/3dsafety/download/mf2015_eng.pdf Gas evolution during FDM 3D printing and health impact

- ↑ http://built-envi.com/portfolio/ultrafine-particle-emissions-from-3d-printers/ Gas and particles emissions from 3D printers

- ↑ http://3dprintingindustry.com/2015/10/28/toxic-abs-pla-fumes-3dsafety-org-inquires-vocs/ How toxic are ABS and PLA fumes ?

- ↑ http://sentryair.com/blog/health/3d-printing-are-there-particles-how-about-fumes/ 3D printing are there particles how about fumes

- ↑ http://www.dezeen.com/2016/02/16/health-study-reveals-harmful-toxic-effects-hazards-3d-printing-illinois-institute-technology/ health study reveals harmful toxic effects hazards 3d printing illinois institute technology

- ↑ http://www.aafeurope.com/en/150/en1822

- ↑ http://www.berriman-usa.com/tutorial_2_air_purifiers.htm Filtration efficiency curve

- ↑ http://www.buyactivatedcharcoal.com/how_to_make_activated_charcoal How to activate Charcoal

- ↑ http://www.thingiverse.com/thing:125264 DIY Scrubber with mask filter

- ↑ http://3dprintclean.com Commercial external filtered enclosure

- ↑ http://buzzbox.apogeescience.com/ Commercial external filtered enclosure

See also

External links

In addition to site licence GFDL1.2, this page is also released under license CC BY-SA 4.0