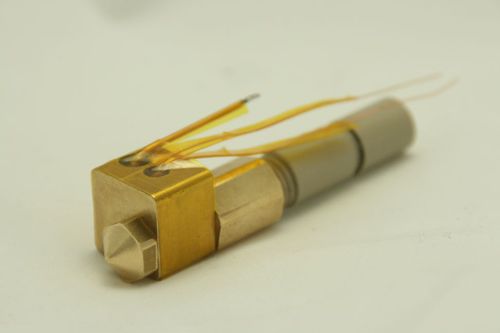

Geeksbase hotend V1

Release status: working

| Description | A new hot-end for the most DIY 3D printers

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | []

[] [] |

| External Link | []

|

Contents

Introduction

This hot-end is made for the most 3D DIY-Printers. If the adapter doesnt fit. Its possible to add an holder.

- It is electrically and mechanically near to the mendel-parts-hotend or stoffels single-hotend. We designed it new to have the possibility to change the nozzle without loosing the good heat performance.

- You could use the hotend direct with a prusa and all prusa-variations. For mendels its good to make the isolator longer, otherwise the hotend is not long enough to look throw the carriage.

Files

Main features

- possible materials to print: ABS,PLA,HDPE

- changeable nozzle (change the printnozzle in about 60 to 120sec.)

- easy to mount, fits in the most extruders with adapter 10mm

- seperated Heat and Cold-zones

- Isolator made of Peek natur GC30 (tempstable up to 300°c)

- all parts made of high quality brass (MS58)

- different nozzle sizes (0.7-0.5-0.35-0.25mm)

- NEW HOTZONE - printspeeds with ABS up to 200 , with PLA up to 300 , HDPE (in development)

Orginal information (links)

Hole story of development of the geeksbase Hotend V1.0

Design information

We want to build a hotend which works with PLA and ABS. It must be possible to change the nozzle in a few minutes. heatthermistor and heatsensor must be replaceable too. Replacing and dismounting should be easy.

The isolation should be so good, that the filament only melds in the area where the nozzle is. (avoid ouze) The hotend will be designed for a max. working temperature of 260-280°c, to have some air to the top. To use the new hotend on all of our extruders, we decide to make the isolation with a out-diameter of 10mm. So it should fit on the most extruders.

The different to the most new hotends, we dont! try to make the heatzone as short as possible. In our opinion the hotend need a calculated lenght hotzone to heat up the filament fast enough to reach high speeds!

Hotend construction

The geeksbase hotend V1.0 is made of 4 parts.

- Peek Isolator (polyetheretherketon) with PTFE sliding tube inside

- Adapter (brass MS58)

- Heatblock (brass MS58)

- nozzle (brass MS58)

Peek Isolator

The Peek part is the Isolator. Peek has a temperature stabilty up to 300°C. For a plastic material its really strong. The Peek Isolator as a M10 thread on one side, to screw it in the adapter. A 6mm boring for the PTFE tube is in the same side. On the other side a 3,5mm boring with a big bevel to let the filament slide in easy.

Adapter

The Adapter is made of Brass. Inside a M10-thread on the outside hexagon for a wrench. So it should be easy to screw them together. The M8-Outside-Thread is for screwing the isolator+adapter into the heatblog. Threads demonstrat no really fullcontact between the parts. So the temperature wont spread so much.

Heatblock

The Heatblock is made of Brass. Inside M8-thread to screw in nozzle + adapter. On the side we drill two holes for thermistor and the heat-resistor. So you have access to them the hole time, if anything needs to be replaced. The Heatblock is a bit bigger. So it could buffer and compensate some temperature

Nozzle

The nozzle is made of brass. One side have got the M8-outside-thread and on the other side its turned to a pointed surface. Inside is a 3mm bore wich is so deep, that only a few mm left to the nozzle diameter (example 0.35mm)

Assembly information

Video previews

nozzle change in under 2 minutes (ABS) <videoflash>E2MqfjIHNpA</videoflash>