Genealogy / Archeology of the Greg's Wade's Geared Extruder

"As long as there is filament, there will be the need to push it - and that what Greg's Wade's Geared Extruder was designed to do."

That could be the motto for this extruder design. Why? Because it just works, and works, and works, and keeps on working!

In this page I will illustrate (to the best of my knowledge) how the original design for the Wade's geared extruder has evolved in the last few years. Nowadays (early 2015) this extruder design is probably the most popular single extruder design among reprappers worldwide, and it has spawned countless remixes. It would be impossible to account for all the variants of this design available on the web but I will try my best to show its main "evolutionary line".

- Trivia

- Greg = Greg Frost, engineer, Adelaide, Australia.

- Wade = Wade Bortz, engineer, Vancouver, Canada.

Contents

- 1 1st Gen: Wade's original design

- 2 2nd Gen: (Greg's) Accessible Wade's Extruder

- 3 3rd Gen: Greg's Hinged Accessible Extruder

- 4 4th Gen: Greg's Guidler

- 5 5th Gen: Greg's Wade reloaded

- 6 Concurrent 6th Gen popular designs

- 7 7th Gen design trends: Bowden, fans, newer hotends

- 8 The convoluted history of the gears in Greg's Wade's Geared Extruder

1st Gen: Wade's original design

This is actually documented right here in the wiki: Wade's_Geared_Extruder and you can find all the files for it on that same page.

Now, I understand that the original Wade's geared extruder from February 2010 is itself an evolution of an earlier extruder design by Adrian Bowyer and also includes many ideas from Nophead's early research on extruders. Wade apparently used Alibre, a proprietary CAD program for Windows, to design his geared extruder.

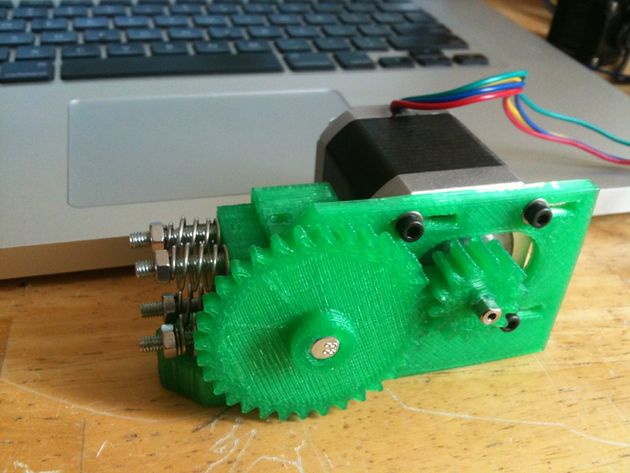

All the files for this early extruder design are still available both here on RepRap.org and also on Thingiverse. One should note that as much as it has been improved upon by later derivative designs (see below), the basic features of this extruder remain exactly the same, five years later: a NEMA 17 stepper motor driving a small gear that drives a big gear whose axle is a hobbed bolt that pushes our filament, with compression provided by a spring-loaded bearing.

2nd Gen: (Greg's) Accessible Wade's Extruder

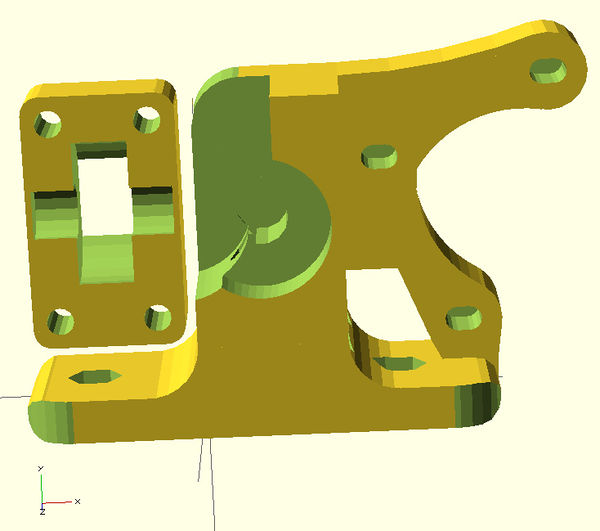

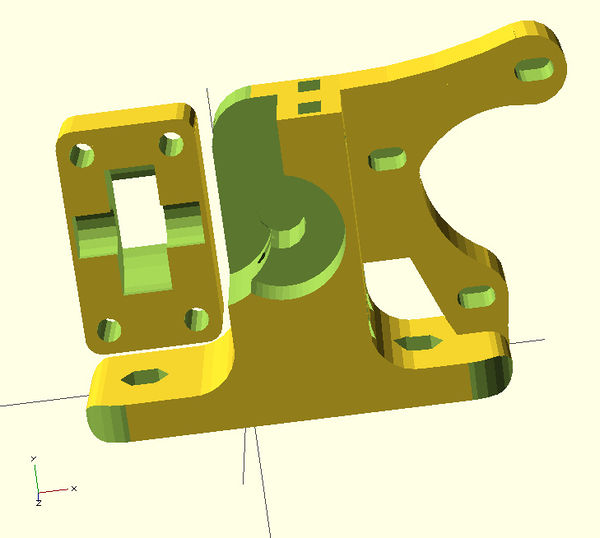

This was published on Thingiverse in February 2011 i.e. about a year after the publication of the original Wade's extruder. Greg redesigned Wade's extruder from scratch using OpenSCAD, a move that imo allowed the design's evolution to really take off.

The OpenSCAD source includes references to Josef Prusa's GitHub repository so I imagine the extruder was designed to be used with the Prusa Mendel, at the time the "current" Prusa design.

File header:

- // Greg's Wade Extruder.

- // It is licensed under the Creative Commons - GNU GPL license.

- // © 2010 by GregFrost

- // Extruder based on prusa git repo.

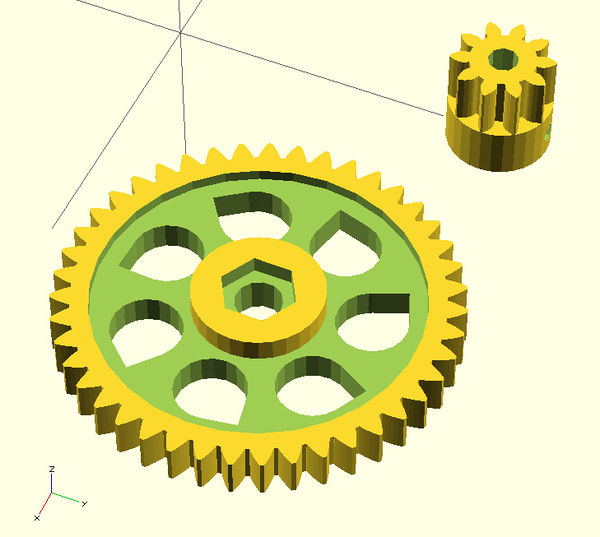

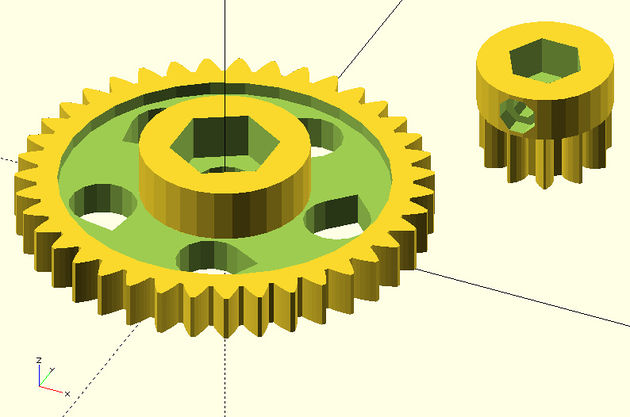

Together with his extruder body design, Greg also published a nice set of gears (gear ratio 10:43), using his own OpenSCAD gear library:

File header:

- // Greg's Wade Gears.

- // It is licensed under the Creative Commons - GNU GPL license.

- // © 2010 by GregFrost

- // Parametric extruder gears based on prusa git repo.

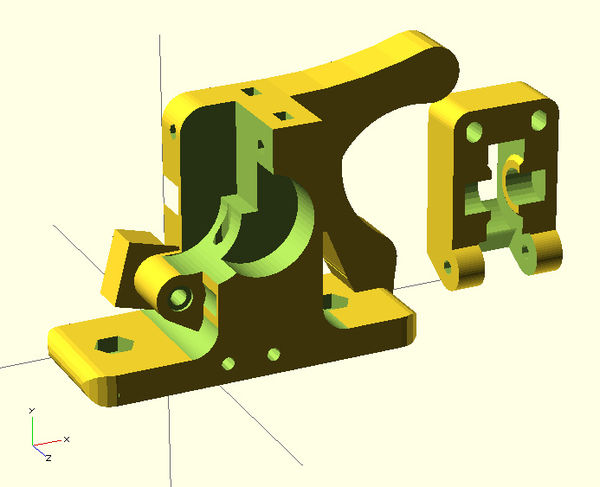

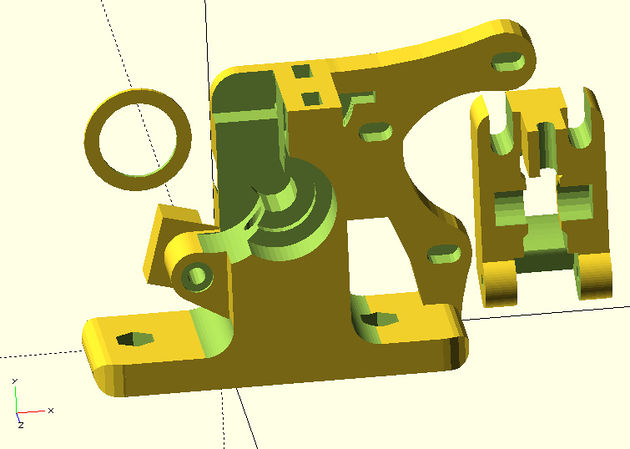

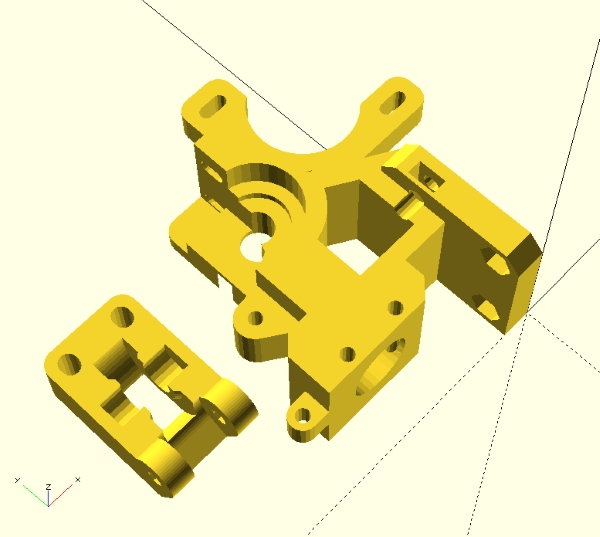

About a month later Greg published version 2 of his extruder, which is pictured below:

3rd Gen: Greg's Hinged Accessible Extruder

Greg published the third version of his extruder on Thingiverse in May 2011, about two months after the publication of version 2. The main improvement is of course the addition of a hinged idler, as the name of the thing indicates. This is how Greg describes his improvements:

- This is an update to my Accessible Wade's Extruder.

- The idler is now hinged using an M3 screw. I have also added support for the central part of the 608 idler so that there is no need to use washers to space the bearing away from the plastic.

- I have been using this design for a while now and love it.

- Changing filament is a simple as compressing the spring then whipping out the old filament and poking the new one in.

The Thingiverse page shows this design was remixed 29 times!

4th Gen: Greg's Guidler

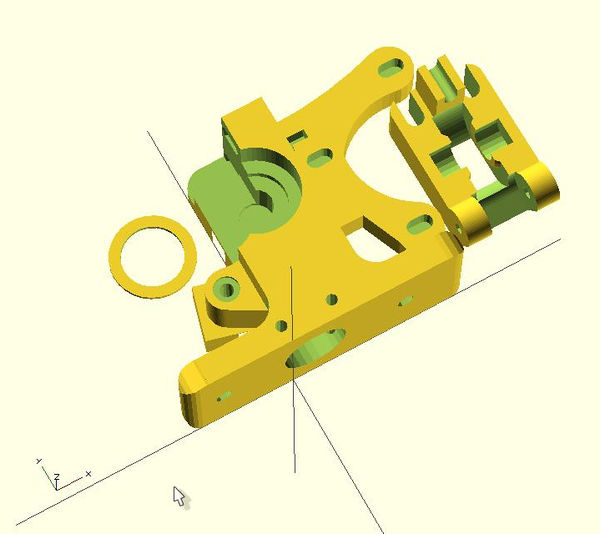

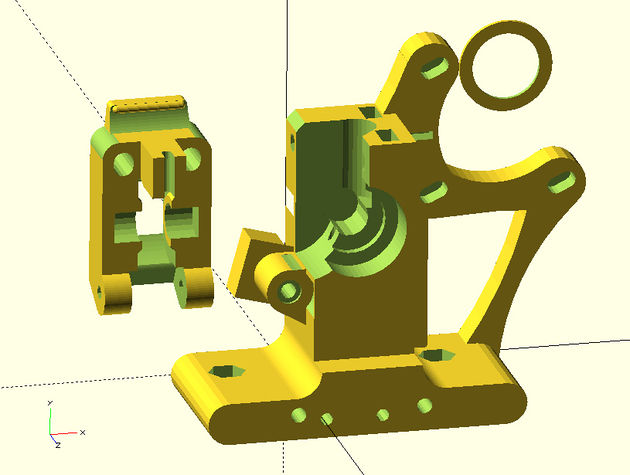

In February 2012 Greg came up with a 4th version of his extruder design, published on Thingiverse as "Guidler for a Gregs Wade", although the newly published thing was really a complete extruder.

Now, why did Greg use the previously unheard of word "guidler"? In Greg's own words:

- Some minor changes to my filament pusher inspired by Tom's update (http://www.thingiverse.com/thing:16928). I have incorporated a filament guide on the idler (and coined the term guidler). I also took his modification so the front bearing doesnt rub and I have included a printed spacer so the bottom bearing doesnt rub either (just insert it before the bearing). I also widened the opening a bit for better access to the hobbing (another of Tom's ideas). I also included one of Triffid Hunter's suggestions to modify the hinge support piece slightly to make it easier to remove.

- Thanks Tom and Triffid for the ideas.

And btw, this happens to be Greg's favorite version of his extruder: http://forums.reprap.org/read.php?1,478177,478330#msg-478330

This thing was remixed 15 times on Thingiverse and among the remixes we'll find what I consider to be the following "evolutionary step" for this extruder design: Greg's Wade reloaded.

5th Gen: Greg's Wade reloaded

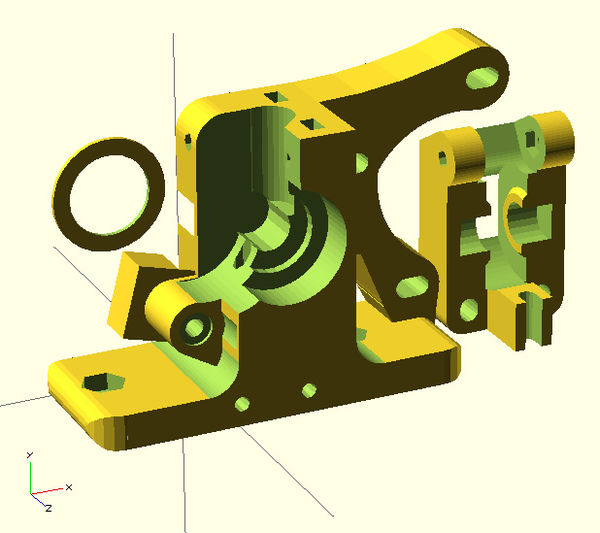

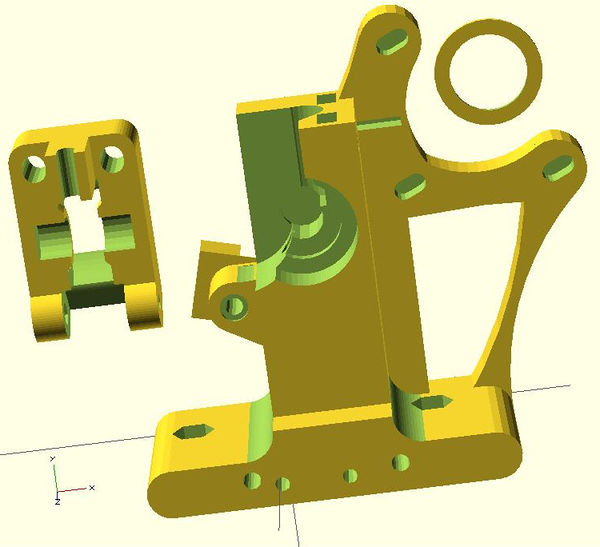

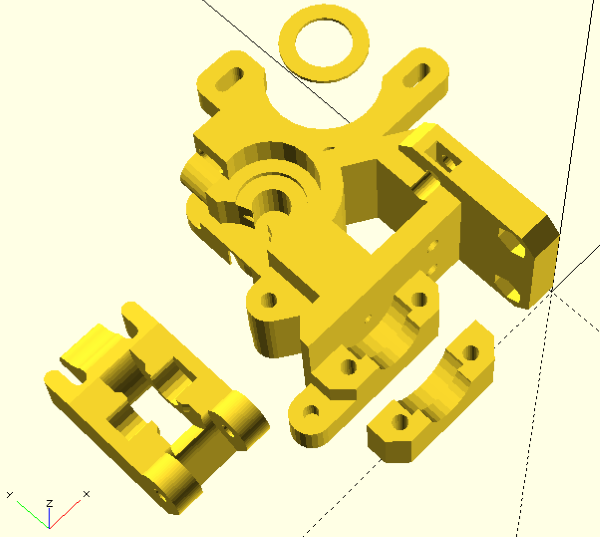

In March 2012, just one month after Greg had published version 4 of his extruder, Jonas Kuehling published his "reloaded" version of Greg's Wade's Geared Extruder on Thingiverse. The list of improvements/modifications is quite extensive:

- This derivative of Greg's Wade Extruder collects all the best ideas and latest features and improvements:

- * Greg's excellent "Guidler" for perfectly lined up filament feed AND easy access of the hobbed bolt

- * Tiltable idler-screws for opening the idler without removing the screws entirely

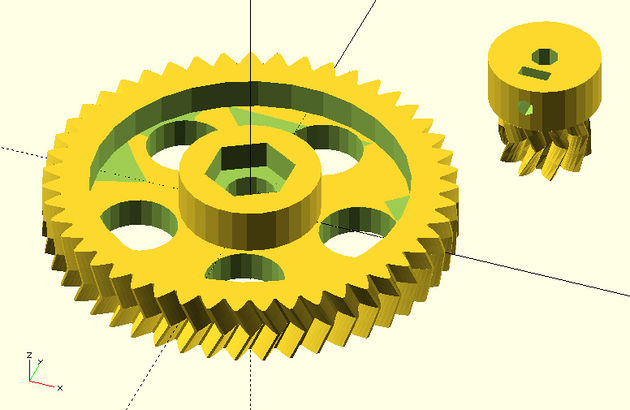

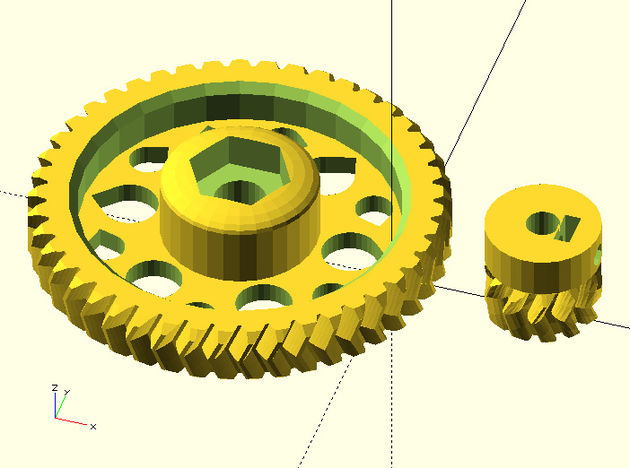

- * 4mm elevation of whole extruder body/bolt/motor mount to allow slightly bigger 9/47 herringbone gears

- * 2mm extra bolt-motor-distance for the same reason

- * M4 nuts and screws for idler, since M3 screws in more than 60mm length are sometimes hard to source (at least in the common hardware stores of northern germany..)

- * Well, 9/47 herringbone gears!

- * All nut-traps have been corrected for correct fit (all prusa parts seem to use slightly wrong sizes.. should be 5.5mm wrench size for M3 nuts, I changed all of them to the right ISO values with additional 0.2mm clearance. Fits great for a precisely calibrated prusa)

- * Additional hotend-mount option "reprapfaborg" for Stoffel15's great hotends that use 10mm shaft diameter of 20mm length (shown on one of the pictures as a cut-view); you can get one via http://reprap-fab.org

- * 8mm thickness of motor mount (instead of 10mm) in reference to wider herringbone gear

Now for the fishbone gears, there is an important detail that is not very clear: Jonas did not provide the source code for them, he actually edited the STLs from this thing: Thingiverse. I went looking for the OpenSCAD source code for the fishbone gears and eventually I stumbled upon a file with the following header:

File header:

- // Wade's Extruder Gears using Parametric Involute Bevel and Spur Gears by GregFrost

- // by Nicholas C. Lewis (A RepRap Breeding Program)

- // It is licensed under the Creative Commons - GNU GPL license.

- // © 2010 by Nicholas C. Lewis

It is quite interesting that Jonas adopted the word "guidler" just one month after Greg had coined it; my guess is the idea was so good that it needed the catchy name that Greg had given it. Another interesting fact is that Jonas' work had so many derivatives (Jonas' thing was remixed a grand total of 67 times!) that 3 years later it has become difficult to distinguish a single evolutionary path from that point on, as there are so many derived extruder designs that are available on the web. Another issue that clouded the evolutionary path here is that Jonas did not add his copyright to the source code, and the only way to distinguish his changes to the source code is using a diff-style program (an automated program that lists the differences between two text files).

Concurrent 6th Gen popular designs

I have chosen only three among the dozens of derivatives of Greg's Wade's Geared Extruder available nowadays (early 2015) to show how the design evolved (and is still evolving!) in the last three years.

Alberto Valero's Bowden remix

The idea of using a Greg's Wade's Geared Extruder with a Bowden filament system dates back to November 2012, when Alberto Valero published on Thingiverse his remix of Jonas Kuehling's Greg's Wade's "Reloaded" (with OpenSCAD sources, based on Jonas Kuehling's sources):

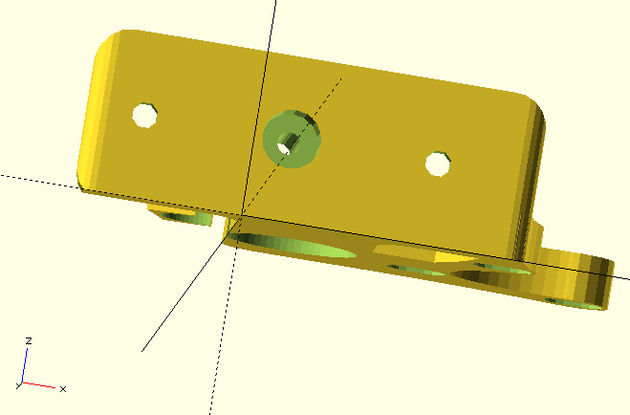

It is of course very similar to Jonas Kuehling's version. The difference lies in the underside of the extruder, where one can force-thread a push fit connector:

Misan's "Bob's your uncle" remix

Misan's "Bob's your uncle" version of Greg's Wade's Geared Extruder was published in March 2013 on Thingiverse and designed for the Prusa i3, the design of which had just been published by Josef Prusa. The Prusa i3 was the "hot new kid on the block" among 3D printer designs at the time and Misan's "Bob's your uncle" version of Greg's Wade's Geared Extruder almost immediately became extremely popular among reprappers building an i3 or even considering a build.

Misan's version is based on Greg's code but incorporates some of the improvements/modifications in Jonas' "reloaded" version. Also he is using the exact same fishbone gears as those in Jonas' "reloaded". There is the same issue with Misan's published version as with Jonas' version: he too, forgot to add his copyright or any clear indication of his changes of the source code.

Ch1t0 rotated versions of Greg's Wade's Geared Extruder

Published by ch1t0 (Ramon Garcia) in April 2013 on Thingiverse.

By reading the comments I have determined that ch1t0 took Greg's design and imported it in SolidWorks (a proprietary CAD program), then made all his changes and added his own original (or not? hard to tell at this point, see the Discussion tab for details) ideas. However, ch1to never published (as far as I can tell) his SolidWorks files (but in comments he said it can send the sources by email), thus hampering further remixes of his design. In fact, by breaking the OpenSCAD design chain, ch1t0 effectively signed the death sentence for this particular "evolutionary line" of the Greg's Wade's Geared Extruder, as far as I am concerned. And that's a pity, because his version is really very interesting.

The i3 Rework problematic rotated versions of Greg's Wade's Geared Extruder

In July 2013 eMotion-Tech, a French company based in Toulouse, published on Thingiverse the complete set of STL files for their i3 Rework version of the Prusa i3, based on earlier work on the Prusa i3 EiNSTeiN variant. Among these STL files was their derivative of Greg's Wade's Geared Extruder.

Whereas Misan's version of Greg's Wade's Geared Extruder strives for simplicity, the i3 Rework version of Greg's Wade's Geared Extruder is more original in the sense that it rotates the whole body of the extruder in relation to the X-axis: the gears are now perpendicular to the X-axis. This in fact leads to a rearrangement of the various elements of the extruder but still, it retains all the features that the Greg's Wade's Geared Extruder is known for. Another very important innovation in the i3 Rework extruder is that the layer fan is integrated in the design, it is not an afterthought.

Now, the big problem here is that, contrarily to Misan's work, the i3 Rework extruder design has some serious issues with its copyrights and is not compliant with the GPL:

- Source code or CAD files are missing.

- Incorrect attribution.

In fact the i3 Rework extruder is a trivial remix of the extruder published by ch1t0.

Wade L3K

Published by skarab (Sébastien Mischler) in October 2014 on GitHub.

This is a remix version of ch1t0's STL files (with the rear base of the rework version) designed from scratch on Sketchup. The first goal for this remix is to improve the guidance of flexible filament by integrating the filament guide in the body closer to the hobbed bolt. Unlike these direct fathers it is open source but also break the OpenSCAD chain.

7th Gen design trends: Bowden, fans, newer hotends

In late 2014 / early 2015, we are seeing some trends in the continued development of Greg's Wade's Geared Extruder.

- Use of Bowden-type filament feeding systems with Greg's Wade's Geared Extruder. There are three reasons for this. First, linear delta printers have been developed and to keep the mass of the effector as low as possible, the extruder is attached to the frame and feeds filament to the hotend on the effector through a Bowden system. Second, the desire to lower the mass of the X-carriage in Cartesian-type printers such as the Prusa i3, which leads to less vibration and more accurate prints. And third, the use of multiple hotends, which necessitates the use of Bowden systems because of the lack of space to hold multiple extruders on a moving part. Unfortunately not a single developer of these Bowden remixes seems to have picked up the early work of Alberto Valero.

- Integrated fan systems.

- Newer hotends. Hexagon, E3D.

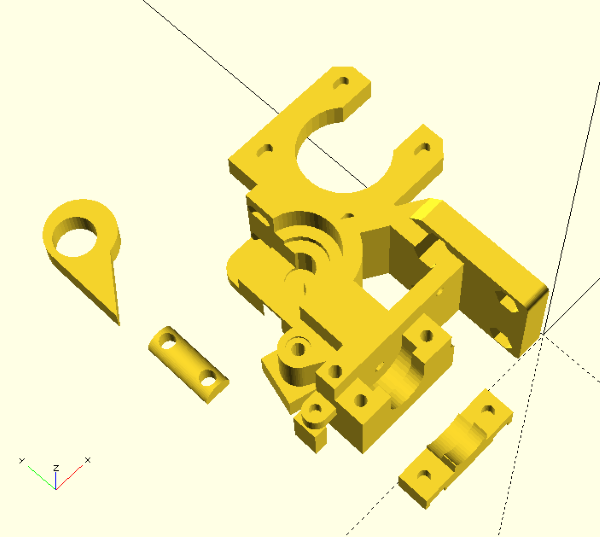

In August 2015, I (AndrewBCN) published on Thingiverse the Ultimate Greg's Wade's Geared Extruder, which is actually a small evolution of Misan's "Bob's your uncle" version. I have also included the OpenSCAD source code for the fishbone gears (see next section below). The idea here is to have a complete, maintained set of OpenSCAD source code files for various versions of Greg's Wade's Geared Extruder. In other words, a common source code base and not the dozens of separate versions that are rather impossible to maintain.

Right now the Ultimate Greg's Wade's Geared Extruder covers the following configurations:

- A large variety of possible hotend mounts.

- Both 24mm and 30mm spaced X-carriages are supported.

- Both 1.75mm and 3.00mm filament diameter versions are supported.

- Gear ratio is configurable.

- Various tolerances and dimensions can be configured.

- A Bowden version is available with the option of a mounting bracket or just the normal base. See Ultimate Greg's Wade's Geared Extruder - Bowden version

The planned evolution of this design includes adding a version with Prusa i3 Rework mounting (hence fixing the basic issue of lack of source code and proper licensing examined above).

Additionally, a complete, integrated layer fan system is available as an add-on for the Ultimate Greg's Wade's Geared Extruder, see Configurable 40mm fan duct / mount for Wade's extruder for details.

The convoluted history of the gears in Greg's Wade's Geared Extruder

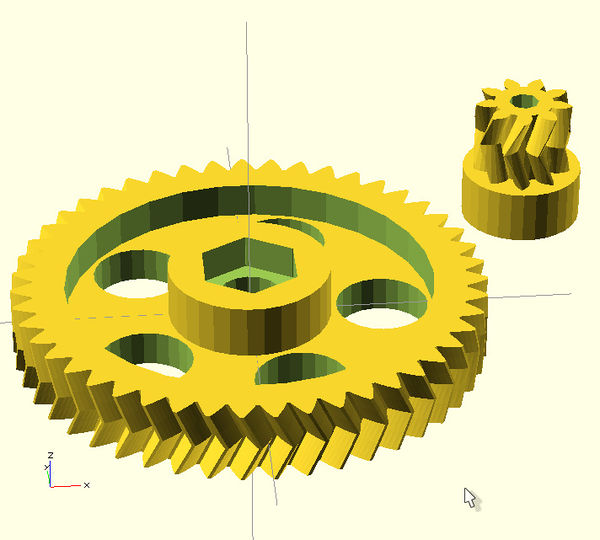

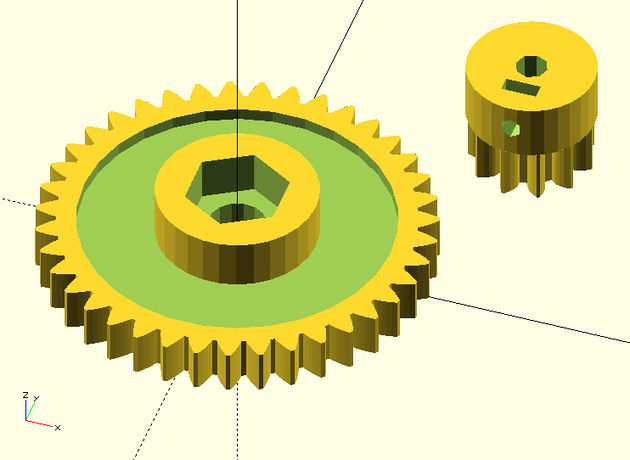

The modern "fishbone" or "herringbone" gears used with most recent versions of Greg's Wade's Geared Extruder did not appear out of a vacuum, they also have their own history, which is also derived from the original Wade's extruder gears pictured above.

But first things first: why does the small gear in Greg's Wade's Geared Extruder use an M3 grub screw and nut? Well, probably because nophead published a version of this gear for Wade's extruder in April 2010 on Thingiverse http://www.thingiverse.com/thing:2521 with this feature. Also note that nophead added a small base to fit the grub screw and nut.

Six months later, in October 2010, Nicholas C. Lewis published on Thingiverse the OpenSCAD sources for a complete set of gears for Wade's Extruder (using Greg Frost's involute gear library), with nopheads additional M3 grub screw and nut. http://www.thingiverse.com/thing:4305

In a separate development, on December 11 2010, Rhys Jones published an improved version of Wade's extruder with herringbone gears, however he did not use Greg Frost's library or OpenSCAD. Nonetheless it is the earliest occurrence of the use of herringbone gears for Wade's extruder that I could find. http://www.thingiverse.com/thing:5111

Quoting Rhys Jones:

- "As the name suggests, the design uses Herringbone gears. This ensures that backlash is substantially reduced, which should result in the extruder requiring slightly less reverse, but more importantly run quieter."

Also on December 19 2010 Greg Frost published the OpenSCAD source for a set of (straight) gears for Wade's extruder, which was based on Nicholas C. Lewis's earlier design and code. http://www.thingiverse.com/thing:5213 Note how similar this set of gears is to the one he would publish only two months later with his first version of Greg's Wade's Geared Extruder. As we can see, there is an added nut trap (M5 I assume) to reinforce the base of the small gear, but Greg himself seems to have done away with this feature in his later work. Also note the teardrop shaped holes in the large gear; these holes are not just for decoration, they are also used to access the innermost screw for the stepper.

Finally, just a few days later on December 23 2010, Stoffel15 published his version of Wade's extruder with herringbone gears "Wade goes fishing", improving upon the OpenSCAD code from Nicholas C. Lewis's earlier design. http://www.thingiverse.com/thing:5268

It is clear now that Stoffel15 was the first one to offer herringbone (fishbone) gears with their OpenSCAD source for Wade's geared extruder, and that later versions of Greg's Wade's Geared Extruder which offered fishbone gears were based on his early work.

Fast-forward to May 2015, Frans-Willem Hardijzer published on Thingiverse a new code base (still using Greg's involute gears library) for the fishbone gears for Greg's Wade's Geared Extruder. In August 2015, I (AndrewBCN) slightly remixed Frans-Willem's excellent OpenSCAD source code and published a set of fishbone gears matching the Ultimate Greg's Wade's Geared Extruder.