Kettle Hat Hot End

Release status: Experimental

| Description | Acorn type hot end

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

The kettle hat hot end is a DIY hotend intended for those who don't have a lathe.

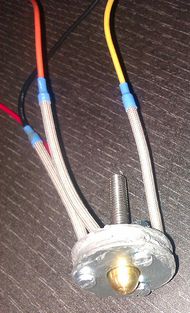

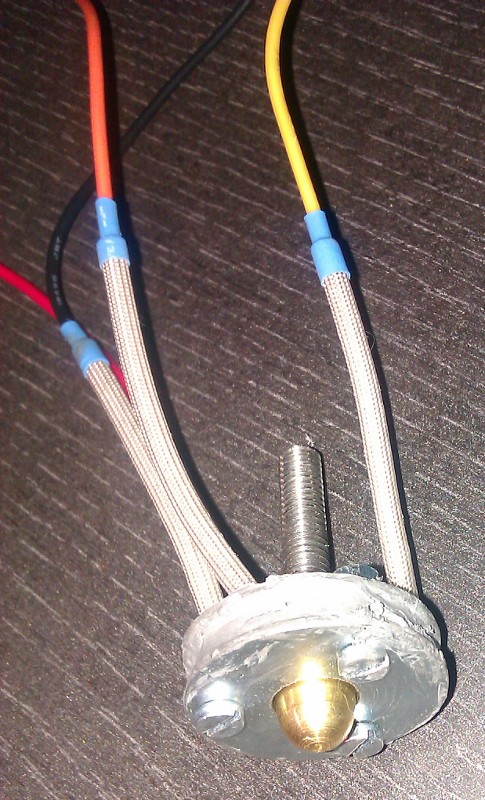

At first you need a M6 acorn nut made of brass (DIN 1587) with a 0.5mm hole at the top, a 40 mm long M6 threaded rod made of stainless steel with a drilled trough hole of 3.2 mm, a washer with 30 mm diameter, and an M6 nut.

There are 3 types of holes in the washer: 8 mm, 3 mm and 2mm.

Now assemble the parts:

Wind insulated nichrome wire around the base of the acorn nut and fixate a termistor to the nut. Insulate the wire with silicone tube.

Now take a second washer and omit the 2 mm holes. Instead of 8mm the big hole has a diameter of 9.5 mm this time.

Assemble it in front of the first washer.

Now, put some fire cement between the washers and carefully heat it up in order to dry the cement.

Use core end sleeves to attach the wires and insulate properly.

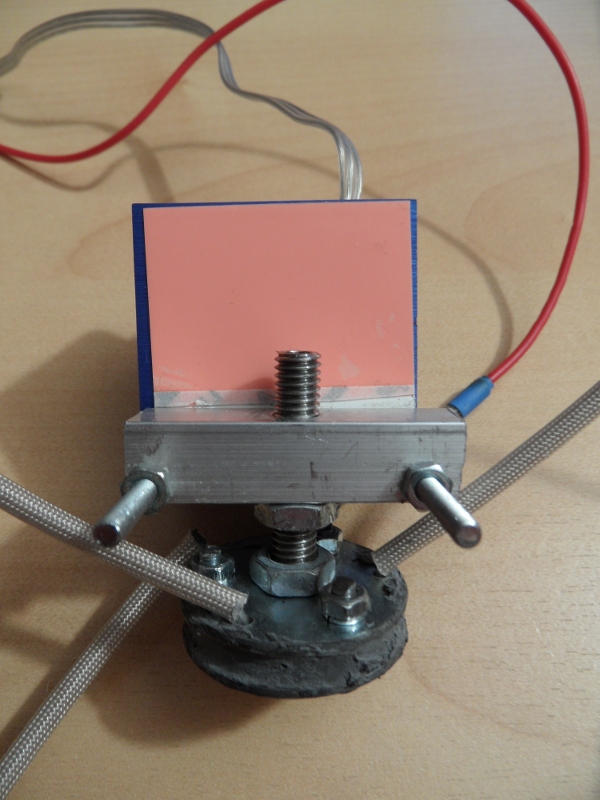

Hotend together with a cooling fan (Northbridge).