Longsword Hotend

Release status: Obsolete

| Description | hot end with cooling fan

|

| License | unknown

|

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

The Longsword Hotend is replaced by its successor, the Organ Pipe Hotend.

This page describes the Longsword hotend.

Introduction:

Meanwhile there are a lot of hotends available. Most of them require a lathe to make them.

The Longsword differs from those hotends in 3 major aspects.

1.) The Longsword does not require a lathe. All you need is a drill press and some other ordinary tools.

2.) The Longsword does not consist of PEEK.

3.) The Longsword isn't just simply a hotend, but rather thought as a kind of hotend construction kit. That means you can make parts like the cooling bar and the lower barrel from other materials as steel or brass, just to try them out. You won't need to build a whole new hotend.

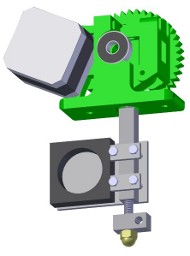

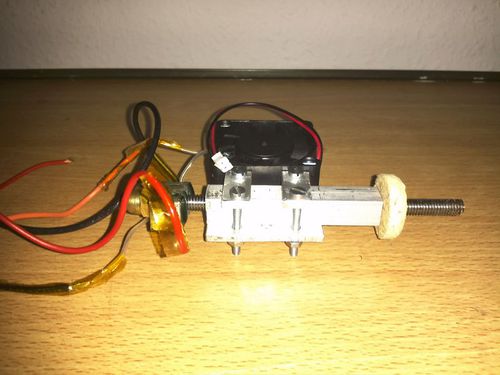

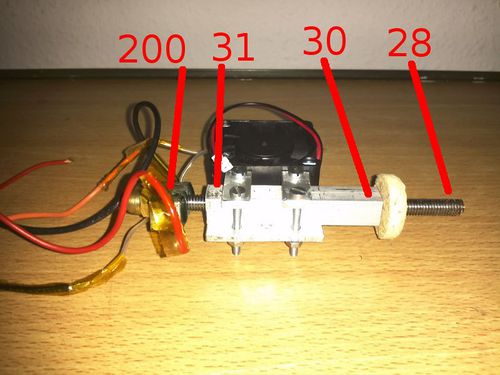

Overview:

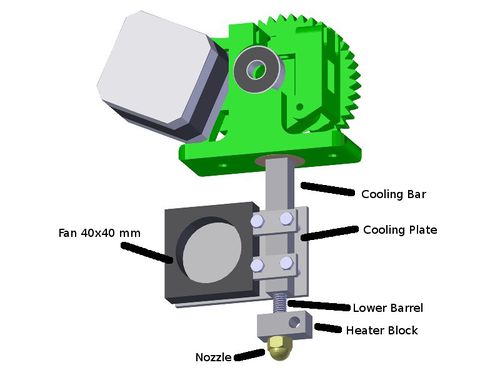

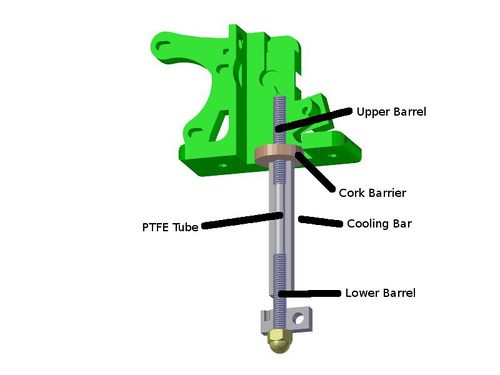

Parts:

Upper Barrel: Stainless Steel, M6 threaded rod, 3.3 mm bored through, 40 mm long

Cork Barrier: Cork, 22mm OD, 6 mm ID, 6 mm long

Cooling Bar: Aluminium, 10 x 10 mm, 60 mm long, 4.8 mm bored through, M6 threads at both ends

PTFE Tube: 4.7 mm OD, 3.2 mm ID, 33 mm long

Cooling Plate: Aluminium, 60 x 40 x 3 mm

Fan: 40 x 40 mm, 12V

Lower Barrel: Stainless Steel, M6 threaded rod, 3.3 mm bored through, 40 mm long

Heat Block: Aluminium, 10 x 10 x 20 mm

Nozzle: Brass, M6 Acorn Nut, 0.5 mm

Bar Clamps: Aluminium, 20 x 10 x 3 mm

All Screws M3. Use M3 nuts between fan and cooling plate to get distance for airflow.

The bigger holes in the cooling plate are irrelevant. Use a Tube Sharpener to chamfer the ends of the PTFE tube.

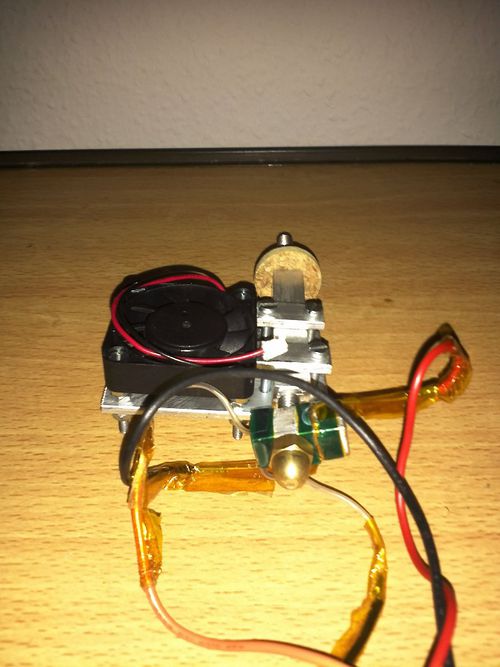

Assembly:

Temperature:

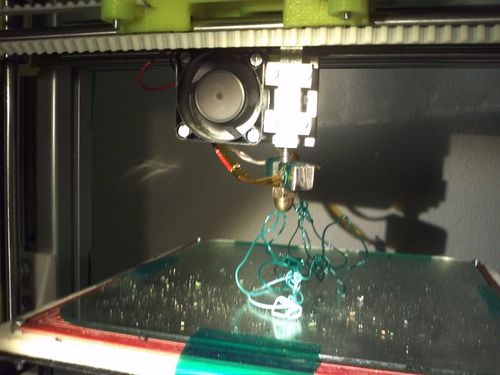

Extruding: