Multicolor-extruder

Release status: Experimental

| Description | Multicolour extruder

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Multicolor Extruder is developed by Rong Guo from Mixshop 3D Printer base on Mix Extruder G1. This project is still under development, the hardware parts are mostly done, waiting for the software development to make it completely working. All its mechanical design are open source, you can find it at: onbook.com

Contents

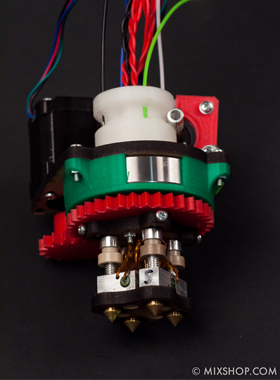

Overview

This extruder is designed to print up to four colours or materials with only two driving motor.

It consists of 4 hot-ends, one of the stepper motors used to switch between hot-ends while printing. Each hot-end may have a specified task assigned, one for infill (larger nozzle size), one for support (PVA), and two smaller sized nozzles for two colour printing of outer layers. Later testing also can be done for electric conductive materials and materials with elasticity. The possibility of 3D printing can be limitless with all those different materials and an extruder that is able to use and cooperate them in a single print.

Design Goals

- ONE complete set of Extruder can print 4 different colours/materials

- Compatible to RepRap 3D Printers including Prusa i3 and Mendel

- Nozzle diameter 0.34mm

- Minimize the size of Multicolour Extruder

- Simplicity: fewer than 15 parts.

- Hardware cost: less than $150 USD.

- Layer resolution: 0.13 - 0.2mm height

Design Description

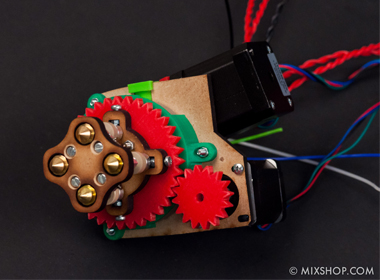

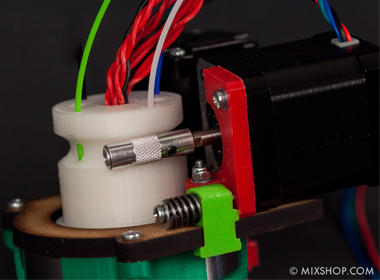

Each hot-end has individual thermistor and resistor, which allows different temperatures for different materials.The gears are driven by an additional stepper motor to rotate and switch between hot-ends. The wood pieces that locks below the heat blocks were there to make sure each hot-ends are straight and equally spaced, so the position will still remain the same after rotation. Each hot-end was lock by a screw right below the big gear, so the height of each hot-end can be easily adjusted. A 6008z ball bearing (68x40x15) was used inside the extruder to provide smooth rotation when changing hot-ends. A spring by the edge of the device pulls the side of filament driving motor forward, with a screw and nylock nut that locks the motor in place but still allow it to rotate, they generate a rotational momentum for the motor, and pushes the aluminum hobbed tube against the filament.

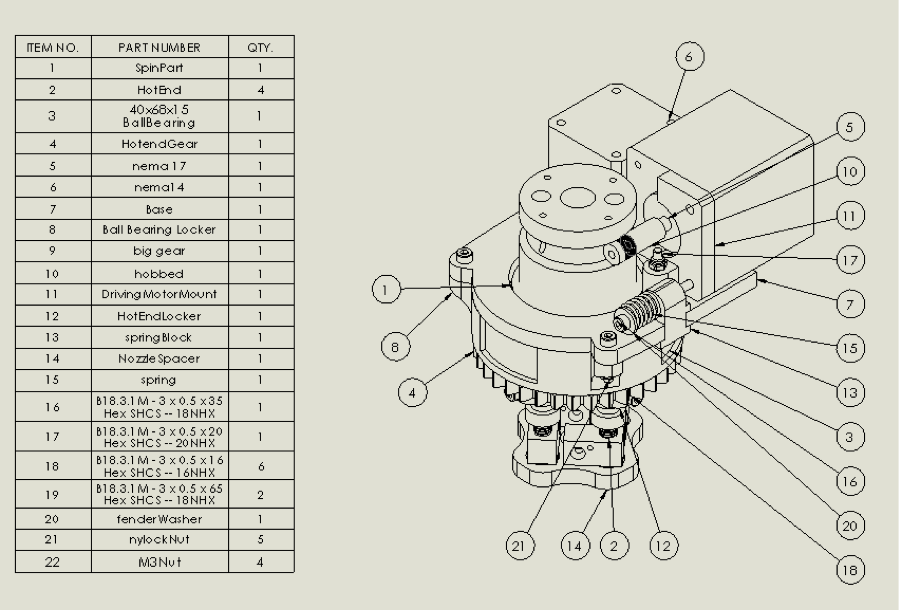

Bill of Material

Following table is a part list of the extruder: RAMPS 1.4 has only two sets of thermistor pins and terminals for the hot-end thermistors and resistors. Therefore only two different temperature are allowed currently or you can use the heat bed terminal and thermistor pins for an additional temperature control.

Download STL files

You can download the STL files at: ONBOOK

Where to Get it

You can buy the complete developer kit at Mixshop

Video

Video: https://www.youtube.com/watch?v=om5Rz4aBA4A&feature=youtu.be

Remaining Issue

The primary testing stage for mechanical parts have been done, the thing that is left to do is to develop a firmware that fully supports this multi-material extruder.

Current slicers use T0, T1… commands to change between extruder. What we need is that once the printer sees the switch extruder command (T0, T1), the stepper motor that switches the hot-end turns 45 degree.

Or we can do this in another way, keep the firmware the way it is, and modify the slicer. For example if we want to change from hot-end 1 to hot-end 2, slicer provide G-code like this:

...

T1 (switch to the motor that turns the hot-end)

E 45 (turn 45 degrees)

T0 (switch back to the driving motor)

… Both ways will work. The slicer that’s best to begin with might be slic3r (www.slic3r.org), since it already supports more than 3 extruders for 3 different tasks (perimeter, infill, support).

We are here to share this design and provide development kit for anyone who are interest and might be able to modify the program. The development kit can be purchased from there: www.mixshop.com.

The first person who is able make this multi-colour extruder to work and share the results will win a 3D printer of any model that’s provided in our website.