North90's hot-end V2

Release status: Working

| Description | Easy to build Hot End V2 by North90ty

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

This is an upgrade of: North90's hot-end This Hot End is designed to be build with simple tools and without the need for great engineering skills.

Main differences with hot-end v1:

- no thread tapping needed

- nozzle is hold in place by crimping with a tube-cutter

- nozzle to insulator attachment is more leak proof

Thermal design

see: http://www.reprap.org/wiki/North90%27s_hot-end#Thermal_design

Tools and supplies

- Drill + drill bits

- Vice

- Tube-cutter (see notes below)

- File(s)

- Cutting oil (olive oil works great)

- Metal hack saw (fine saw for metal)

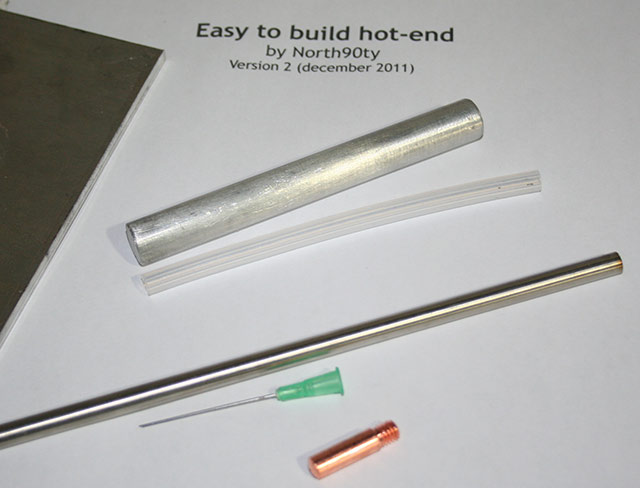

- Stainless steel tube with an outside diameter of 1/4" (6.35mm), thin wall diameter (6mm od will work as well, description is for 1/4")

- PTFE tube 1/8"(3.18mm)(3.5mm is fine too) inner diameter and 5.5-6.5mm (~1/4") outer diameter

- welding nozzle 0.6mm (0.023")

- injection needle 21-22GA (to make the nozzle smaller than 0.6mm) try to find a needle with a 0.6-0.7mm od.

- Piece of aluminium sheet 5-6mm thick as a mount and heatsink

Most supplies can be bought on ebay

Stainless steel tube

You need a piece of stainless steel tube with a small wall thickness. Here i used tube that is 6.35mm(1/4")od and 5.84mm(0.23")id. Basically any tube can be used, but the thicker the wall, the longer you need to make the insulator. Minimum recommended inner diameter is 5mm. If you have to reduce the wall thickness, use the procedure shown here: http://www.reprap.org/wiki/North90%27s_hot-end#How_to_build_the_stainless_steel_insulator drill tube tube out to 5.5-5.7mm

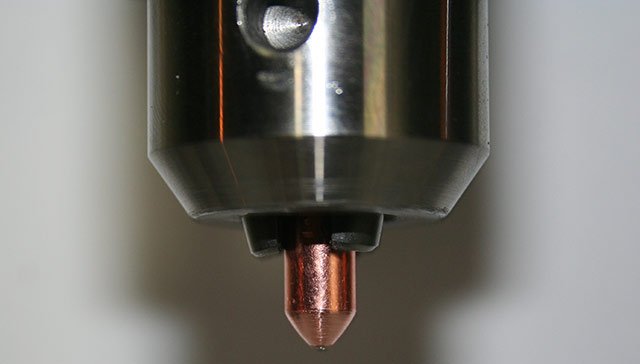

Nozzle out of welding tip and injection needle

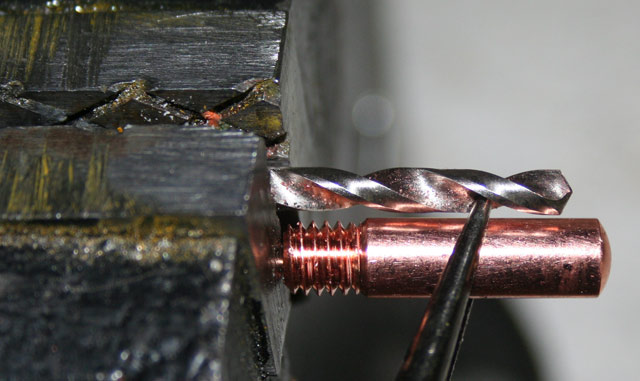

Drill the tip out to 3.5mm, up to 2-3mm from the end.

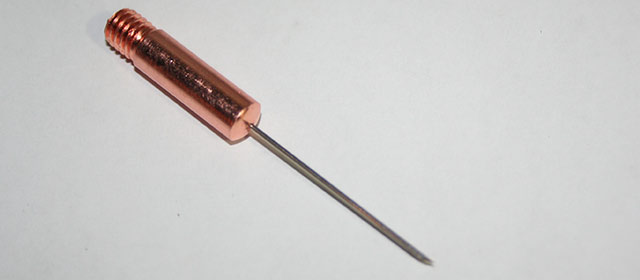

Manually drill a injection needle through the tip (21.5GA or 22GA works). If the needle slides through the hole (small needle): cut the base of the needle and slide it through the welding tip form the top.

Cut the base of the needle with a dremel with cut-off disk, pull the needle all the way down. (check if you made a clean cut and the needle is still hollow)

Cut the sharp end of the needle (dremel cut-off disk), and put the welding tip in the drill. Use a file to sharpen the welding tip. If your needle is small and loose in the welding tip: hammer all around on the tip of the welding tip, it might take a while but you'll tighten the hole and seal the needle in. Alternatively you can clamp the tip of the welding tip in a vice, turn it around a few times and make sure the needle is fixed. If you work carefully, you'll only damage the part of the tip that is sharpened with a file anyhow.

Put the welding tip up side down in the drill and reduce the diameter until it fits snug into your stainless steel insulator. To reduce the diameter: turn the drill on and hold the file against the welding tip. File small bits off at a time! It doesn't matter if it is a little loose.

Cut the threaded piece of the welding tip off, you only need about 5mm of the welding tip in the insulator.

Insulator

Put an about 7 to 15 cm long piece stainless steel tube in the drill. First reduce the diameter of the PTFE (teflon) liner to fit in the stainless steel tube:

- sharpen one end of the PTFE tube (pencil sharpener)

- put a piece of rod in the tube to make it stiff (a 1/8 drill will work)

- slightly sharpen the end of the stainless steel tube

- hold the PTFE tube with pliers and slowly drill the stainless steel tube over/in it

- REMEMBER THAT PTFE FUMES ARE BAD! so don't go fast and overheat it!

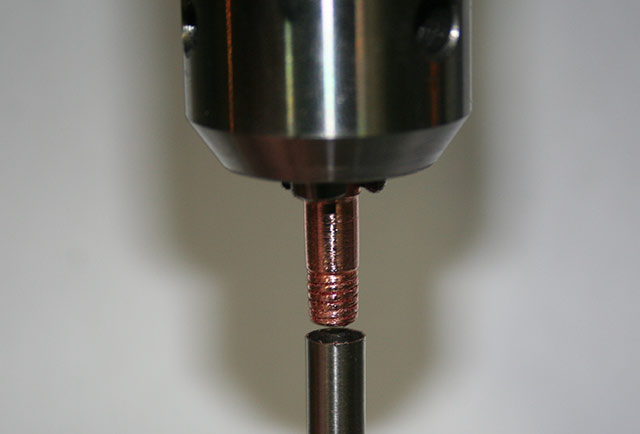

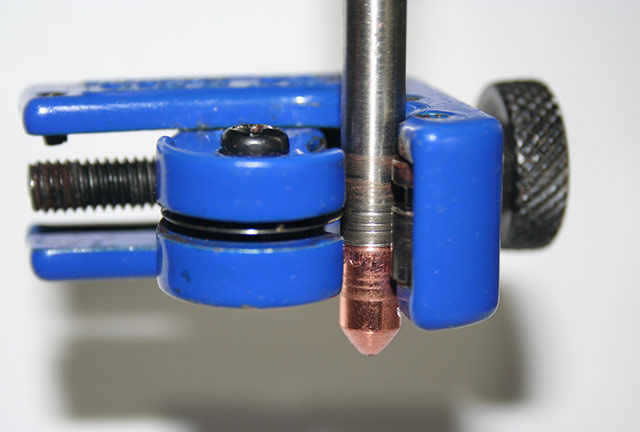

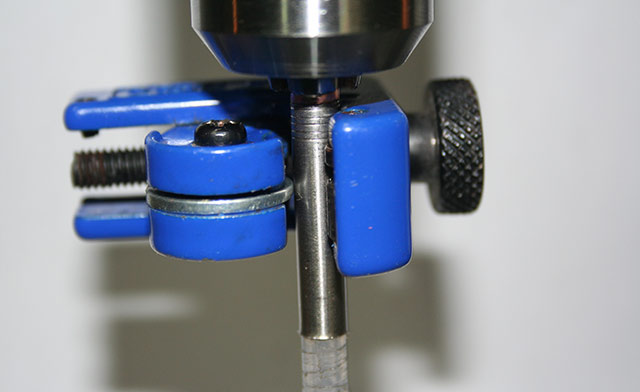

Put the nozzle in the tube. ONLY TURN THE DRILL BY HAND! Use a tube cutter to "crimp" the insulator to the tube (only light pressure is needed, more turns at a light pressure is best). If you tighten the cutter too much you will cut the tube in half!

I dulled an old tube-cutter, but i tested a brand new sharp one and it works as well.

Crimp the insulator at 3 or 4 spots to securely fasten it to the nozzle.

(this procedure might seem difficult, give it a try and you'll be an expert in no time!)

Now cut off the stainless steel tube at the length you want it (guideline: choose >40mm for 5mm inside diameter, and >20mm for 5.84 inside diameter). Flare the end of the tube with a large drill-bit. (flaring makes the insulator easier to mount to the heatsink/baseplate, because it can't fall through).

Now take the cutting wheel out of the tube-cutter, replace it with a normal steel washer. Insert the PTFE tube. Make certain the the end of the ptfe tube that is touching the nozzle is cut of straight. If it isn't straight, plastic will flow in between making switching colors of filament take longer. When the PTFE is in place, crimp the tube at 1-3 spots with the modified washer-tube-cutter.

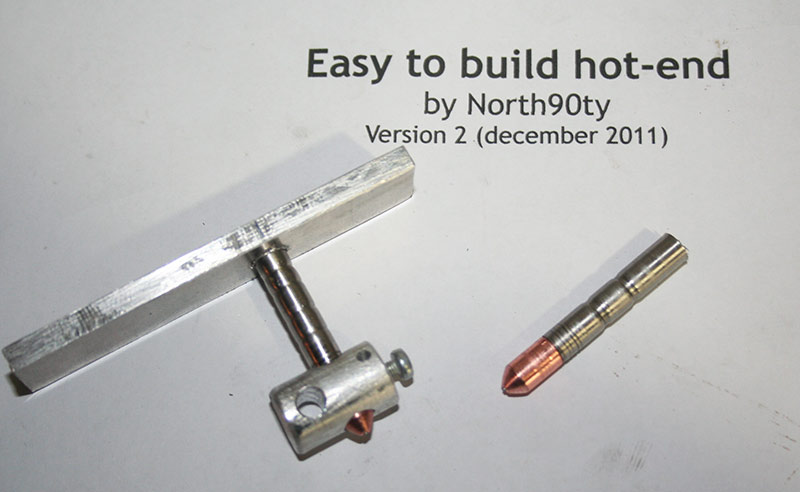

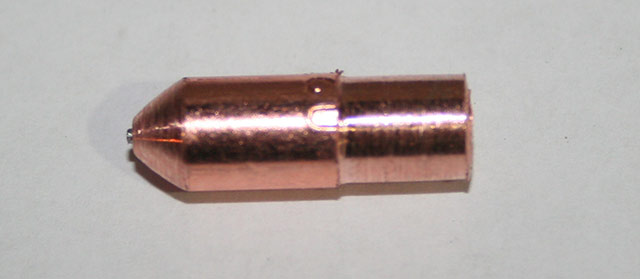

The finished insulator+nozzle. The crimps in the insulator keep the PTFE liner firmly in place. Drill the insulator out to 3.5mm (it has to be larger than the filament because the filament swells when it heats up).

Mounting the insulator to the heatsink/baseplate

See http://www.reprap.org/wiki/North90%27s_hot-end for a heatsink and mounting design.

When you flared the insulator tube, you can simply drill a 6.35mm(1/4") hole and glue the insulator in with heat resistant glue.

Heater block

This heater block can be made out of aluminum or brass, rod or square stock. Any diameter between 10 and 15mm should work.

- drill a hole for the resistor (often 5-5.5mm) as close as possible to one end

- drill at a right angle from the previous hole a hole for the insulator 6.35mm (1/4")

- drill at a 45degree angle a hole for the thermistor (2.5-3mm)

- cut off the rod about 4mm from the insulator hole

- drill a 2.3-2.5mm hole in the center of the rod, into the insulator hole

- tap M3 thread in this hole for a retainer screw. If you don't have a m3 tap: just use a m3 bolt, a self-tapper or even a woodscrew. Aluminium and brass are soft enough!

How to get the Hot End to print

- Clean out all parts. You do not want pieces of metal to jam in the nozzle.

- Add the heater and temperature sensor of your liking. Place the heater as close as possible to the nozzle (NOT like in the picture above)

- Mount to your extruder.

- Print.

Upgrades and improvements

- [NOT TESTED] If you flared the insulator tube, you can make the heatsink/baseplate by using two aluminium sheets -- e.g, 2mm and 4mm -- and make the hole for the insulator in the 2mm sheet with the same diameter as the inner diameter of PTFE, in this case, 3.5mm. Put this sheet above the 4mm sheet, and screw into the extruder. Don't need to crimp the PTFE nor to glue anything at all. -- Xoan Sampaiño

- Instead of a resistor, you can use a 4 to 6 Ohm length of fine nichrome wire. Carve your heater block into a bobbin shape instead of drilling a hole for the resistor. Use Fire Cement or Fire Rope Adhesive to insulate the block from the wire, then add another layer on top of the wire to seal it in. Retrofit with nichrome wire if you keep blowing your resistors up.