Pinch wheel variations

Please do not add to this page. (It is slightly overcrowded as it is.)

This Page Contains multiple RepRap development projects and should be split up. Each individual project/design/improvement should have its own development page within an encompassing category.

Release status: Obsolete

This is the place to post variations on the pinch mechanism used by the Thermoplast Extruder Version 2.

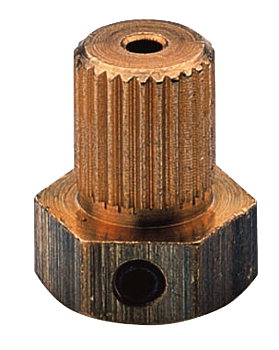

Adding commercial splined drives

A good way to make a drive is to use these splined model-car inserts:

From [Conrad Electronics]. There is a large selection of different sizes available. Search for "insert brass" on the site.

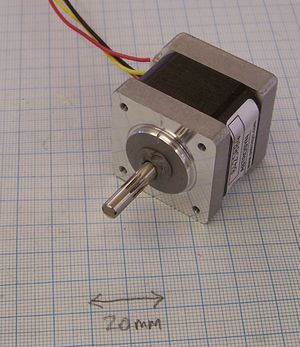

Get your stepper to put splines on its own shaft

- Main article: Splines on motor shaft

Knurling the motor's shaft

Stepper motors should NEVER be disassembled ! The rotor will be demagnetized by a great deal and the motor loses most of its torque. DO NOT do that !

You´ve been warned ...

This is only difficult because it needs special equipment - a lathe and a knurling tool. Given those two, the task becomes quite easy.

NOTE: simply taking apart and reassembling some modern stepper motors can cause the magnets inside to become demagnetized, permanently reducing the motor's torque. This procedure may damage your motors!

NOTE: some stepper motors have hardened shafts and cannot be knurled. You can check by scratching the shaft first with a file; if it cuts easily you're good to go. If not, you might damage your knurling tool.

Start by using a felt-tipped pen to mark 6 mm along the shaft from the face of the motor; that is 6 mm from the flat plane where the screw holes are, not from the raised boss in the center. This will be where the polymer filament will run.

Take the motor apart and removing the rotor. The rotor is intensely magnetic and will pick up any small pieces of steel from the vicinity, especially swarf in the lathe and elsewhere. So do this in clean conditions, or - when you reassemble the motor - some particles may get included and cause it to jam.

Leave the stepper motor's ball race on the end of the shaft that you are going to knurl - you won't be able to get it back on afterwards if you take it off. (I discovered this at the cost of one motor...)

Put the motor's long shaft in the lathe chuck by a few millimeters and tighten the chuck gently. Put a centre in the tailstock and use that to locate the other end of the shaft. Tighten the chuck firmly.

Set the lathe to its lowest speed.

With the lathe still stationary, put the knurling tool in the tool post and line it up with the shaft. Make sure your pen mark is within the section that will be knurled, though it doesn't have to be dead centre.

Open the gap in the knurling tool wider than the shaft.

Use the cross slide to move the tool so that it pincers the shaft. Try to get it as central as possible - that is, get it so that each knuring wheel is pinching across a diameter of the shaft and is not offset. Tighten the knurling tool finger tight.

Check that nothing will foul as the lathe rotates by turning the chuck by hand.

Turn the lathe on. Gradually tighten the knurling tool (this will probably need a spanner).

You can stop the lathe in mid-knurl to see how things are going. When you do this, leave the knurling tool in place.

You want to end up with a knurl that is even and about 0.5 mm deep.

When you have finished take the rotor out of the lathe and inspect it carefully for small magnetic particles attached to it. Remove any you find.

Put the stepper back together.

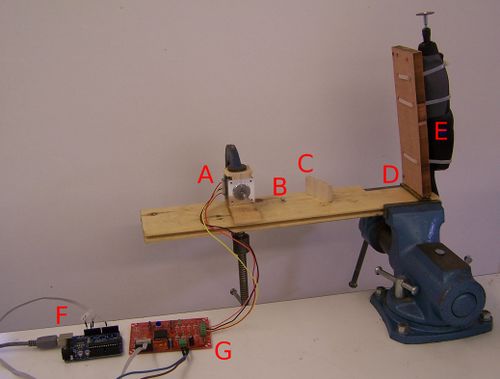

It is sometimes also possible to knurl the shaft with the entire motor intact. This shows that being done. Put the knurled end of the shaft nearest the chuck, and the motor and any extended opposite shaft at the tailstock end.

Putting a knurled sleeve on the shaft

If you go all weak at the knees at the thought of taking your expensive, precision stepper motor apart, but you want a knurled drive, then turn down a 20 mm length of 8 mm diameter brass bar to 7 mm (or start with 7 mm diameter if you can get it; 8 mm is a much more common size, though).

Then touch a centre on one end, and use that dent to support the free end with a centre in the tailstock, as above.

Then knurl that end, again as above, taking care thet the knurling tool doesn't collide with anything.

Then drill a 5 mm hole down the middle of the bar.

Drill and tap M3 a cross-hole at the non-knurled end, file a flat on the end of motor's shaft at the free end, and put a set-screw in your M3 hole to hold the sleeve you've made on the shaft. Note that the set screw grips the shaft beyond the point of contact with the filament. That is to allow that point to be as close as possible to the motor's body, and hence to the bearing in the motor that takes the sideways pinch force.

Knurling without a knurling tool

On Andy Hall's blog he describes how he's made a knurled sleeve for a pinch extruder using a technique known as "hobbing" shown on Andy Kirby's blog for making worm gears. See those two links for details.

Nophead posted the results of some fairly extensive testing. Short version is that the M3 worm pulley gives the best traction so far. It is also possible to cut the worm gear with nothing more that some nuts, bearings, a table vise, and a hand drill.