Prusa Mendel Assembly

|

English • العربية • български • català • čeština • Deutsch • Ελληνικά • español • فارسی • français • hrvatski • magyar • italiano • română • 日本語 • 한국어 • lietuvių • Nederlands • norsk • polski • português • русский • Türkçe • українська • 中文(中国大陆) • 中文(台灣) • עברית • azərbaycanca • |

Contents

- 1 Before You Begin

- 2 Assembly Instructions

- 2.1 Frame Triangles

- 2.2 Front Threaded Rods

- 2.3 Rear Threaded Rods

- 2.4 Top Threaded Rods

- 2.5 Tightening the Frame

- 2.6 Assembling the Y-axis

- 2.7 Assembling the X-axis

- 2.8 Assembling the Z-axis

- 2.9 Installing the X Carriage

- 2.10 Attaching the Print Bed

- 2.11 Wiring the electronics

- 2.12 Firmware Calibration

Before You Begin

Before assembling a Prusa Mendel, make sure you have all the parts necessary. For the bill of materials, see Prusa Mendel.

If you're building Iteration 2, take a look at Prusa_Mendel_Assembly_(iteration_2) as the parts and build is slightly simplified without the use of glue.

For the visually oriented, have a look at this photo gallery of an ongoing Prusa Mendel build.

You may also want to watch the complete video series for assembling a Prusa 2 How_to_build_Prusa_2.

Notes:

- Heating the flat side of a bushing with a hair dryer or heat gun before snapping onto the smooth bar can keep it from snapping.

- If you're using serrated washers these should only be used between nut and plastic - nut-to-fender and fender-to-bearing washers should be flat.

- You may also care to look at Adrian's Prusa Notes, which show how he puts a Prusa Mendel together.

- Although most steps are absolutely harmless when done right, you still might want to take precautions for your Health and Safety.

- Variations on the Prusa Mendel may require different instructions. Search for your variant in this wiki before attempting to modify existing instructions.

Assembly Instructions

Frame Triangles

This step takes about 15 minutes per triangle, for a total of 30 minutes.

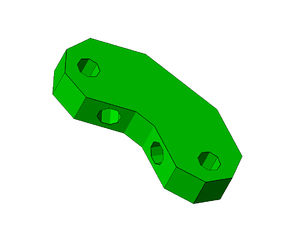

There is a triangle on each side of the Prusa RepRap. You will need to make two of these and then connect them together (in the next steps) to form the Prusa frame. Each side is an equilateral triangle with a frame vertex on each corner. You can use either footed or non-footed vertices to build this. (The footed ones look better, but are not critical.) The instructions assume you are using footed vertices.

Parts Required (per triangle)

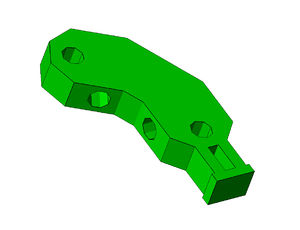

- 2 RP footed frame vertices

- 1 RP frame vertex (non-footed)

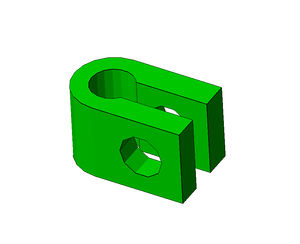

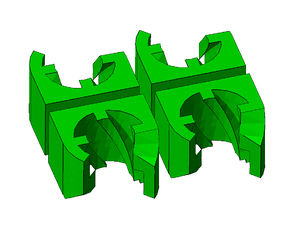

- 1 RP bar clamp

- 3 370mm M8 threaded rods

- 14 M8 nuts

- 14 M8 washers

- (Optional but recommended) A piece of threaded rod or wood or any other material with precisely 290mm length. This is your frame jig J1.

- Take one of the 370mm threaded rods, and slip an M8 washer onto the middle of it.

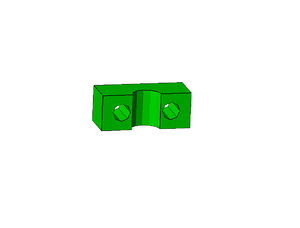

- Take the RP bar clamp (the U-shaped bit with the two holes) and slide the threaded rod through the two holes until the clamp sits next to the washer.

- Slide another washer onto the rod from the other side.

- Thread two M8 nuts onto either side of the clamp, until they are next to the washer, but do not tighten them yet.

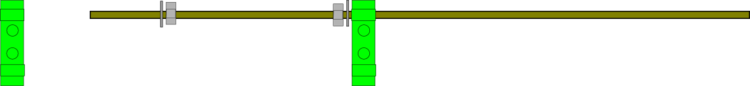

- Thread another two nuts on each side of the rod, followed by washers. See the picture for what it should look like. <flickr>5188262096|thumb|right|m|The bar clamp on the threaded rod.</flickr>

- Slide the rod through the wider bottom (footed) side of two vertices. Make sure the feet point in the same direction, and the bulge on the non-footed sides of the vertices point outwards.

- Measure the distance. The distance between the two vertices should be 290mm (along the rod, equivalent is 11-13/32"). Get it approximately right now, we will check this again later. If you have a frame jig, place it between the two vertices and adjust the nuts until you can just barely fit the jig J1 between them.

- Place another washer and nut on the other side of the vertex. Tighten, but not too much. We'll need a bit of flexibility here still.

- Take another 370mm M8 threaded rod and place a nut followed by a washer at each end.

- Place one end of the threaded rod into the one of the two footed frame vertices. It should be in the same plane as the first threaded rod. Fix it in place with a washer and nut. You should now have two sides of the equilateral triangle.

- Take the third piece of threaded rod and put a nut and washer on each end. Place it in the other footed vertex and fix it in place with a washer and nut. You should now have a triangle of threaded rods with two footed vertices on two of the corners, nothing in the third corner, and a bar clamp between the two vertices.

- Take the third vertex (non-footed) and slide it onto the threaded rods in the final corner of the triangle. Measure the lengths of the three sides to make sure they are all 290mm long (along the rod from plastic part to plastic part, equivalent is 11-13/32"). Adjust the nuts to make sure this is so. Use the frame jig J1 if you have one. Once done, place a washer and nut on each of the two rods at the top of the vertex. Tighten all the outer nuts. <flickr>5188259098|thumb|right|m|The finished frame triangle</flickr>

- You should now have a sturdy triangle with equal-length sides, two feet on the bottom, and a bar clamp between the feet. Adjust the nuts around the bar clamp (but do not crush the bar clamp together yet) until it's approximately in the middle of the rod. Leave the nuts there loose. See the photo for what you should have at this point.

- That's it, that's one of the triangles done. Repeat the entire procedure for the second triangle. It is identical to the first.

To make sure the holes line up, you can lay the triangles on top of each other and insert six M8 bolts through the each hole in the vertices. The bolts should go through holes in both vertices easily, adjust the frame a little if necessary.

Next we will connect the two frame triangles to form the Prusa RepRap frame. The easiest way to do this is to thread everything onto the front and rear threaded rods and attach those to the triangles first, and then thread the top rods through. That's the method the instructions below will follow.

Front Threaded Rods

This step takes about 30 minutes.

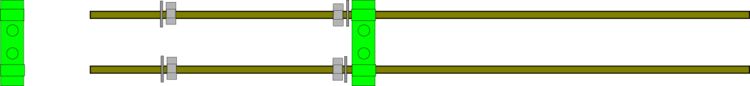

These two threaded rods are used to connect the front/bottom vertex of each triangle as well as to attach the y stage bars and y motor bracket to the frame.

Parts Required

- 2 assembled frame vertex triangles

- 2 RP bar clamps

- 1 RP y motor bracket

- 17 M8 nuts (or 16 under the described modification)

- 20 M8 washers (or 17 under the described modification)

- 2 M8x30 fender/mudguard washers

- 1 608 bearing

- 2 294mm threaded rods

Instructions

- Thread the bottom rod first. Thread an M8 nut onto the middle of the rod. Slide an M8 washer next to it.

- Thread the rod through the bottom hole of the RP y motor bracket. The bottom hole of the bracket is the larger one on the long, straight side.<flickr>5373622677|thumb|right|m|The long, straight side of the RP y motor bracket will be parallel to the ground when you are done.</flickr>

- Slide another washer onto the other side of the bracket and add another M8 nut to hold it in place.

- Add a nut and washer to each end of the rod.

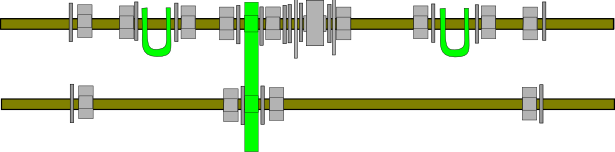

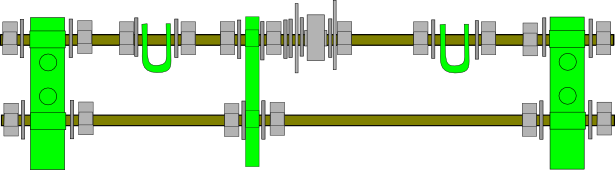

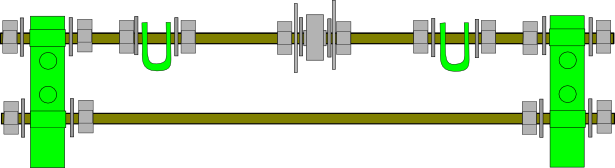

- Now thread the top rod. This is a complicated one, so make sure you get it all done in the right order. From left to right, the rod should have: 1 washer, 2 nuts, 1 washer, 1 bar clamp (threaded through the holes), 1 washer, 2 nuts, 1 washer, the y motor bracket (pointing out towards you), [1 washer, 1 nut, 2 washers,] 1 fender/mudguard washer, 1 washer, 1 608 bearing, 1 washer, 1 fender/mudguard washer, 2 nuts, 1 washer, 1 bar clamp (threaded through the holes), 1 washer, 2 nuts, 1 washer.

- When you hold it with the protruding part of the motor bracket pointing towards you, it should look like the picture below. Verify this now. NOTE: This diagram and the text above show a washer, a nut, and two more washers on the top rod immediately to the right of the motor bracket. This is inconsistent with the assembly pictured below in Assembling the Y axis, where they are missing and the fender/mudguard washer contacts the bracket directly. Photos have been found of completed printers featuring both assemblies. It appears that unless you have a motor with a rather long shaft, the current drive pulley requires assembly per the Y axis diagram below. The diagram shown here will not work as the pulley will not align with the bearing. You can verify this for yourself on your build by holding the motor in place on the y motor bracket and considering the position of the pulley when mounted on the motor shaft. In operation, the toothed part of the pulley needs to line up with the bearing. The extra washers and nut mentioned above are a spacer to achieve this, and should be included only if necessary.

- You can now attach this setup to the triangle sides. Make sure the protruding part of the motor bracket points OUT of the triangle. Thread the ends of the rods through two of the footed vertices. Put a washer and nut on the end of each threaded rod. It should now look like this:

If you are using a wide belt on your Y axis see Prusa Mendel Wide Belts.

Rear Threaded Rods

This step takes about 20 minutes.

These two threaded rods are used to connect the back/bottom vertex of each triangle as well as to attach the y-stage bars and belt pulley to the frame.

Parts Required

- 2 assembled frame vertex triangles

- 2 RP bar clamps

- 14 M8 nuts

- 14 M8 washers

- 2 M8x30 fender/mudguard washers

- 1 608 bearing

- 2 294mm threaded rods

Instructions

- Thread the bottom rod first. Simply add a nut and washer to each end of the rod.

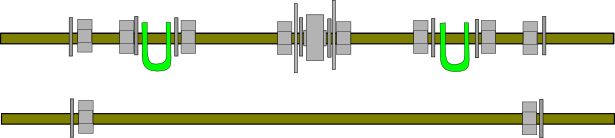

- Now thread the top rod. This is again a complicated one, so make sure you get it all done in the right order. From left to right, the rod should have: 1 washer, 2 nuts, 1 washer, 1 bar clamp (threaded through the holes), 1 washer, 2 nuts, 1 fender/mudguard washer, 1 washer, 1 608 bearing, 1 washer,1 fender/mudguard washer, 2 nuts, 1 washer, 1 bar clamp (threaded through the holes), 1 washer, 2 nuts, 1 washer.

- It should look like the picture below. Verify this now.

- Attach the two rods to the two remaining footed vertices. Thread each end of the rod through the vertex, and add a washer and nut. It should now look like this:

Your frame should now be standing on its own feet without support, but the top vertices of the triangles will still be wobbly. We'll fix that next.

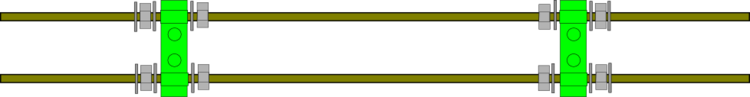

Top Threaded Rods

This step takes about 10 minutes.

These two threaded rods are used to connect the top vertex of each triangle as well as providing mounts for the z-axis motors.

Parts Required

- 2 assembled and connected frame vertex triangles

- 2 RP z motor mounts

- 12 M8 nuts

- 16 M8 washers

- 2 440mm threaded rods

Instructions

- Slide one of the threaded rods through one side of one of the top vertices. Put a washer, two nuts, and another washer on the part of the rod between the top vertices. This is what it should look like when seen from above:

- Repeat for the other rod. It should now look like this:

- Slide the rods through the opposite side vertices. Thread the nuts up to the vertices on each side.

- To each of the four ends of the threaded rod, add a washer, a nut and another washer. Your setup should now look like this:

- Take one of the RP z motor mounts and attach it to the ends of the threaded rods. The side with the two holes should face outwards and the square indentation should face upwards. Add a washer and a nut to the end of each rod.

- Repeat this on the other side. The top of the machine should now look like this:

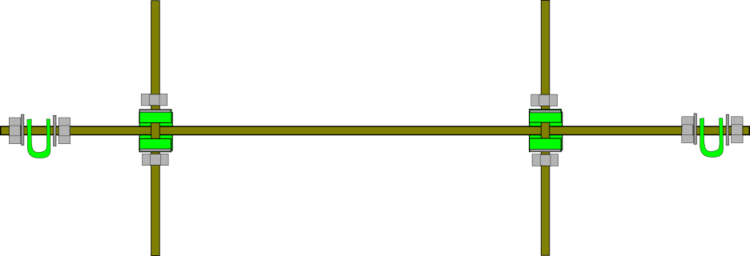

Tightening the Frame

This step takes about 10 minutes.

Now that the frame is fully assembled we can adjust and tighten the nuts on each of its threaded rods. You will need your frame jigs if you have them, or a reasonably precise length measurement tool.

Parts Required

- 2 RP bar clamps

- 4 M8 nuts

- 4 M8 washers

- 1 440mm threaded rod

- (Optional but recommended) A piece of threaded rod or wood or any other material with precisely 290mm length. This is your frame jig J1.

- (Optional but recommended) A piece of threaded rod or wood or any other material with precisely 234mm length. This is your frame jig J2.

Note: If you can't find anything to use as a jig, you could just cut up the cardboard shipping box that you probably just received with all of these parts you are trying to assemble!

Instructions

- Verify that the triangle vertices have distance J1 (290mm, equivalent is 11-13/32") from plastic to plastic along each of the three sides. Once you are sure of this, tighten the outer vertex nuts until they are firm, but do not crush the plastic.

- Adjust each of the bottom rods so that the distance between the inner sides of the vertices is precisely J2 (234mm, equivalent is 9-7/32"). Once you are sure of this, tighten the outer vertex nuts until they are firm, but do not crush the plastic.

- Adjust each of the top rods so that the distance between the inner sides of the vertices is precisely J2 (234mm, equivalent is 9-7/32") and the length of rod extending beyond the vertex on each side is equal. Once you are sure of this, tighten the outer vertex nuts until they are firm, but do not crush the plastic.

- The frame should now be fairly stable. Position the bar clamps on the bottom side of each triangle about 1cm offset from the center of the frame. Do not tighten the nuts either side of the bar clamps yet. These will be adjusted in a later step, assembling the z axis.

- Insert the 440mm threaded rod through the two bar clamps on the bottom of the frame, making sure it is positioned above the bottom rods of the triangles. Note that contrary to these instructions, current recommendation (per Kliment on IRC) is to position the threaded rod below the bottom rods. Otherwise the Y belt can rub against it during operation. Adjust the rod so that the same length sticks out on each side.

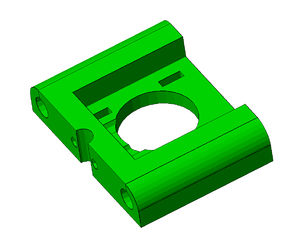

- On each end of the threaded rod, place a nut, washer, bar clamp (threaded through the holes), washer, and another nut. The hole in the bar clamp into which should fit the z-axis smooth rod should be close to the center of the bottom triangle rods. Tip: If you've already installed the 440mm threaded rod on top of the triangle bottom rods and have the clamps in place on it, the easiest way to get the new rod on the bottom is to slide the "Y" axis rods out of the frame and flip the whole thing so that the new rod is on the bottom and the Z rod clamps are pointing toward the front, then reassemble and readjust.

The setup should look like this when seen from above (was below, but now see the end of Instruction 5.):

Assembling the Y-axis

Parts Required

- 4 PLA bushings

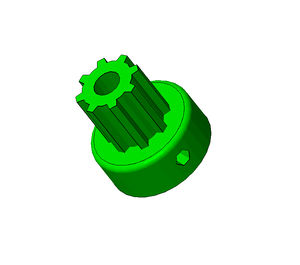

- 1 RP pulley

- 2 RP belt clamps

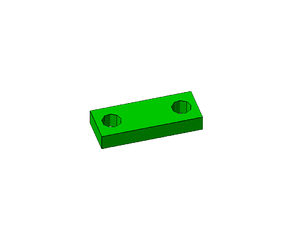

- 1 225×140mm print bottom plate

- 1 225×225mm print top plate

- 2 406mm smooth rods

- 1 840mm×5mm T5 pitch timing belt

- 1 NEMA 17 stepper motor

- 3 M3×10 bolts

- 4 M3×25 bolts

- 8 M3 washers

- 4 M3 nuts

- 1 M3 grub screw

Instructions

- Mark each of the four corners of the print bottom plate 8mm (equivalent is ~5/16") in from each side.

- Carefully drill a 3mm hole in each of these positions.

- Clamp the print bottom plate and the print top plate together, so that the bottom plate is equally far from each edge of the top plate. Drill 3mm holes into the top plate through the corner holes in the bottom plate so that they match on both plates.

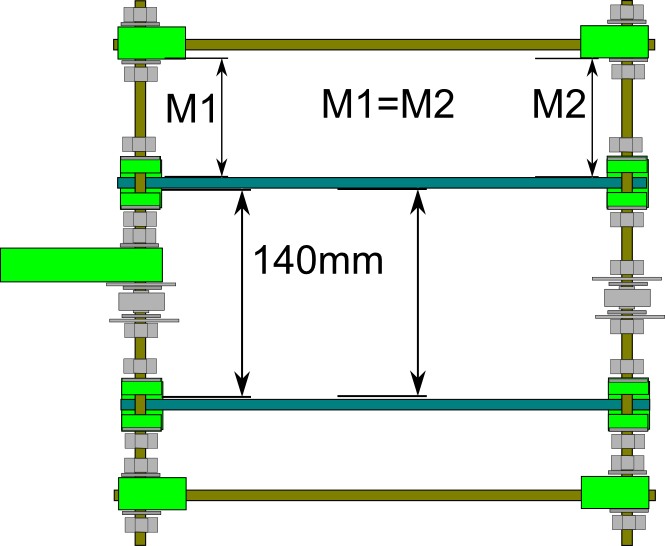

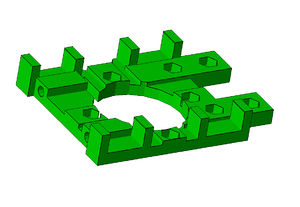

- Slide the two 406mm smooth rods through the bar clamps on the front and rear threaded rods, so that they lie below the threaded rods. They should fit snugly and be approximately parallel.

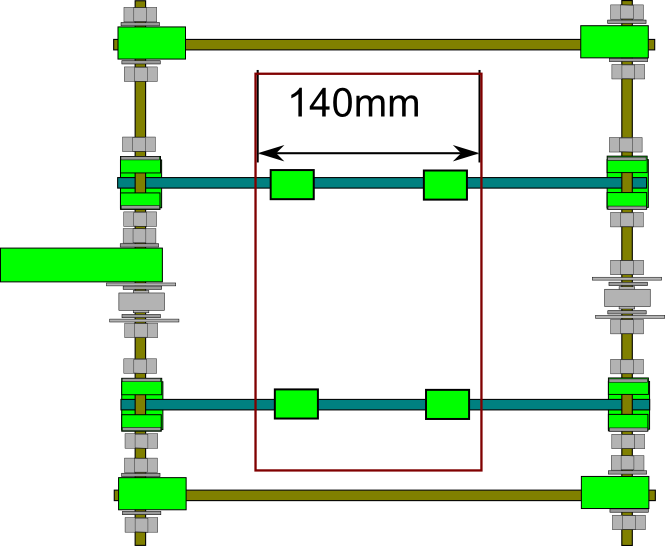

- Place the narrow side of the print bottom plate between the rods. This ensures they are exactly 140mm (equivalent is 5-33/64") apart from each other. Adjust the nuts on the front side bar clamps until the print bottom plate just barely fits between the rods. Try to get them at an approximately equal distance from the middle of the rod.

- Tighten the front nuts just enough that they do not move on their own, but no further.

- Measure the distance from the left front vertex to the left smooth rod. Adjust the distance from the left rear vertex to the left smooth rod to match it. This ensures the left rod is parallel to the frame. Tighten the nuts on the left rear bar clamp just enough that they do not move around.

- Place the print bottom plate next to the left smooth rod on the rear side. Adjust the right rear bar clamp's nuts until the narrow side of the bottom plate barely fits between the rods.

- Recheck the distances from the left vertex to the left rod are the same at the front and rear and that the short side of the print bottom plate fits snugly between the smooth rods both at the front and at the rear. This should ensure that the rods are parallel to each other and to the frame. Use the diagram below to see what it should look like from above.

- Tighten the nuts on all four of the bar clamps now.

- Snap two PLA bushings onto each of the two smooth rods. Make sure they slide freely on the rods, then position them about 120mm apart on each rod, with their top (flat) side facing up. If your bushings are rather stiff, snap them on to one end of a spare length of smooth rod, boil up a fresh mug of water and stand the other end of the rod in the mug until hot. Remove from the mug and slide the bushings down to the hot end. Leave for several minutes and then slide back to the cold end and allow to cool. The bushings should then run more smoothly. (If the bearing are still difficult to move after this technique, it may be necessary to run them up and down along a threaded rod.) Put a dab of glue (Araldite Rapid works well; superglue also works, but doesn't allow for much fine adjustment) on the top side of the bushings. Carefully place the print bottom plate on top of the bushings, so that it's equally far from each of the triangles (see diagram below). Allow the glue to dry.

- While the glue is drying, adjust the position of the bearing on the rear threaded rod until it is exactly aligned with the one on the front threaded rod. Tighten the nuts on the y motor bracket and both bearings at this point. All nuts on the front and rear rods should now be tight.

- Also while the glue is drying, ensure that the hole in the center of the pulley matches the diameter of your motor shaft (it should slide on and fit very snugly). If it is too tight to fit, drill it out. If you find that drilling to 5mm is insufficient to make it fit, and 5.5mm makes it too loose (which it generally will for motors with a 5mm shaft), and a 5.2mm drill bit is too hard to come by, you may find that reaming it with a 5mm allen key will work well, if requiring a bit of manual effort. Alternatively, a needle file can be used to slightly enlarge the hole.

- Insert an M3 nut into the rectangular slot on the base of the pulley. You may need to widen the slot slightly to do this. Make sure that the center of the nut is aligned with the side hole in the pulley that goes to the center hole. Once you are satisfied with the position of the nut, insert an M3 grub screw into the side hole in the pulley. Tighten it until you see the end of the screw inside the center hole, then unscrew it enough to slide the pulley onto the motor shaft. If you find this too difficult, depending on your pulley you may find that the grub screw is able to self tap a sufficiently strong thread into the side hole simply by screwing it in.

- Place the motor with the pulley on it next to the mounting holes in the y motor bracket. Position the motor to the left with the y motor bracket towards you, so that the pulley ends up on the side of the bearing.

- Adjust the pulley position on the shaft so that when the motor is flush with the bracket, the teeth on the pulley are approximately at the position of the bearing.

- Fasten the motor with 3 M3x10 bolts. Put a washer between each bolt and the y motor bracket.

- Recommended: attach the back/bottom of the motor to the bars using zip-ties, kapton tape, picture wire, or any inelastic wrapping. This prevents the Y bracket from flexing with belt tension.

- Tighten the grub screw so that the pulley cannot move along the shaft.

- Position the y belt on top of the print bottom plate and through both of the bearings. Pull lightly on both ends so that it is straight. If the belt is not straight, adjust the position of the rear bearing until it is. Use a marker to mark out the position of the belt on the print bottom plate. Also mark which side of the plate is on the left.

- After the glue has dried, carefully pop the print bottom plate (with the PLA bushings attached) off the rails. Place the two belt clamps perpendicular to the marked position of the belt, several centimeters apart. Make sure the belt position is between the two holes on each clamp. Use a marker to mark where the holes of the belt clamps would be on the plate.

- Carefully drill a 3mm hole through each of the four marked belt clamp holes.

- Place the print bottom plate back on the smooth rods, paying attention to the marking to make sure the correct side is on the left.

- Place one end of the belt, toothed side down, where the holes for the front belt clamp are. Put a washer onto each of two M3x25 bolts, and thread them through the holes in one of the belt clamps. Then attach the clamp to the top of the plate, clamping down the belt. Leave several centimeters of the belt behind the clamp.

- (A 10mm thick print bottom plate is spot on, but if your print bottom plate is 6mm thick, the belt runs about 4mm clear of its top. To get completely parallel running, print two extra belt clamps and position them both under and over the belt. The underneath ones act as spacers.)

- Put two M3 nuts underneath the plate and thread them onto the bolts. Tighten both nuts so that the end of the belt is firmly attached to the plate, toothed side down.

- Pass the belt over the front bearing, around the motor pulley, and then up underneath the plate to the other bearing. Pull it tight, then lay it on top of the plate, toothed side down.

- Put a washer onto each of two M3x25 bolts, and thread them through the holes in the second belt clamp. Then attach the clamp to the top of the plate, clamping down the belt. You can always tighten the belt later with 3 zip-ties: see Tips.

- Attach an M3 nut to each of the two bolts, and pull the belt tight before tightening the two nuts.

- Turn the motor by hand. It should turn with little effort, and each slight rotation should be matched by a slight movement of the plate. You can feel the stepper motor's steps; a single click one way and then a click back again should produce two corresponding movements of the plate. Make sure the plate slides smoothly along the entire length of the rods. Pushing the plate should immediately make the motor turn. Make sure the belt is not too loose (plate and motor should not be able to move independently) or too tight (taking a lot of effort to move the plate). Once you are confident your belt tension is correct, tighten the clamps very firmly. You may now trim the belt, but leave several centimeters behind each clamp for future adjustment.

Assembling the X-axis

BIG NOTE: I have no idea what j prusa was smoking when he designed the v2 parts but your belts for the x axis will NOT be parallel to the smooth rod when viewed from above. Do not worry! This is by design for some reason.

Parts Required

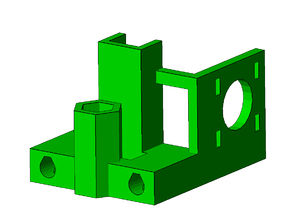

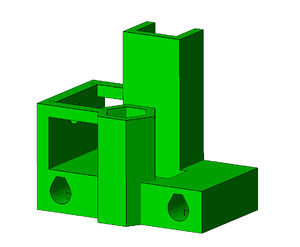

- 1 RP x-end-motor

- 1 RP x-end-idler

- 2 495mm smooth rods (420mm in recent instructions)

- 8 M3 nuts

- 8 M3x10 bolts

- 1 608 bearing

- 2 M8x30 fender/mudguard washers

- 1 50mm M8 threaded rod and 1 M8 nut or 1 M8x30 or longer bolt

- 3 M8 washers

- 1 M8 nut

Instructions

- Drill out the center hole in the hexagonal section of the x-end-idler and x-end-motor parts to 8mm, if it is not already this size.

- Take the x-end-idler part. Check the size of the hole on the flat, thin side surface. If it is 4mm in diameter, enlarge it using a file until it's 8mm in diameter.

- Place 4 M3 nuts in the nut traps in the long channels on the bottom of the x-end-idler part. You may find pulling them into the nut trap using an M3 bolt makes it easier. Thread M3x10 bolts through them, but just far enough that they do not fall out.

- Place 4 M3 nuts in the nut traps of the x-end-motor part as well. Thread M3x10 bolts through those as above.

- Place the x-end-motor and x-end-idler parts 50cm apart, so that the hexagonal sections are facing each other.

- Slide the two 495mm (420mm) smooth rods into the x-end-idler part. Make sure they go past the nut traps.

- Slide the other ends of the rods into x-end-motor part. Make sure they go past the nut traps. The hexagonal sections of the motor and idler parts should still be facing each other.

- Tighten the M3 bolts on the rods passing through the x-end-motor part, so that the part is fixed in place close to the ends of the rods. The motor is usually mounted so that the rods cannot move past the end of the printed part. The x-end-idler part should be able to move along the rods with minor effort. Do not tighten the x-end-motor part bolts yet. Note: on my build, there does not seem to be a large amount of material above these trapped nuts, so you probably do not want to tighten the bolts too much - just enough to hold the rod and no more. If you tighten too much it may cause the part to bulge or even split.

- Thread an M8 nut onto one end of the 50mm threaded rod, if not using a bolt.

- Put the following parts in this order onto the free end of the threaded rod (behind the nut) or M8 bolt: 1 fender washer, 1 M8 washer, 1 608 bearing, 1 M8 washer, 1 fender washer.

- Thread the free end of the threaded rod into the side of the x-end-idler part. The bearing should be on the outside. Put an M8 washer and an M8 nut on the inside and tighten.

Assembling the Z-axis

An alternative, more durable design for the z-axis motor couplings can be found here Mendel: Prusa durable z-axis motor coupling

Parts Required

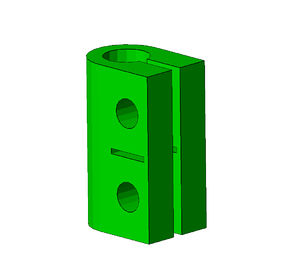

- 2 RP shaft couplers

- 2 RP rod-clamp

- 4 PLA bushings

- 1 x axis assembly (from the previous step)

- 8 M3 nuts

- 20 M3 washers

- 8 M3x10 bolts

- 8 M3x25 bolts (or 8 M3x20 bolts in recent builds)

- 2 NEMA 17 stepper motors

- 2 210mm threaded rods

- 2 350mm smooth rods

- 4 M8 nuts (2 optional)

- 2 8.5mm ID springs (optional)

Instructions

- Use a spirit level to make sure the two rods at the top of the frame are horizontal. If they are not, stack bits of paper under the vertices at the bottom until they are.

- Drop a plumb line (or a nut hanging from a length of yarn) directly down from the indentation on the side of the left z-motor-holder. Adjust the two bar clamps at the bottom of the frame on the left side until the nut falls into the U of the outer clamp. This needs to be positioned so that the polished z-rod is exactly centered and runs perfectly vertical. Repeat on the other side.

- Put M3 nuts into the nut traps on both z-motor-holder ends.

- Put an M3 washer on two M3x25 bolts and thread them into the flat (non-indented) end of a rod-clamp. Attach the rod-clamp to one of the z-motor-holders. Do not tighten. (On some builds, these parts and the shaft couplers seem to be sized for M4 fasteners. Can anyone confirm?)

- Note: The M3x25 bolts are too long for the recent Prusa z-motor-holder and rod-clamp, and the shaft of the bolt interferes with the seating of the z-motor. One can either use shorter bolts (M3x20) or cut the M3x25's to size. An alternative is to use hexagonal bolts, and insert them in reverse with the shaft pointing outwards, using a nut and washer to fix them. But the simplest solution is to turn the bolts round - put the heads in the cavities of the Z motor mounts, have the shafts sticking out, and put washers and nuts on to secure the rod clamps.

- Repeat for the other z-motor-holder and rod-clamp.

- Insert a 350mm smooth rod into the space between each z-motor-holder and rod-clamp. Slide it in from the top. On the bottom, insert it into the U of the bottom bar clamp.

- Using the plumb line, check that the smooth rods are vertical. If they are not, adjust the bottom bar clamp positions until they are. This is critical, so take as much time as you need.

- Tighten the nuts on the bar clamps and the bolts on the rod clamps. Check again with the plumb line, and adjust if necessary.

- Place two PLA bushings on each of the smooth rods. Make sure they slide freely.

- Position the x-axis assembly inside the frame so that the bushing channels on the x-axis-motor and x-axis-idler parts align with the bushings. The x-end-idler part should be on the right, with the bearing on the rear side of the machine.

- Put a blob of glue on the flat side of each bushing.

- Push the rectangular channels of x-end-motor and x-end-idler parts against the flats of the bushings. Position the x-end-motor part against the bushings on the left side of the machine and then slide the x-end-idler part along the x-axis smooth rods until it makes contact with the bushings on the right side of the machine. Let the glue dry.

- While the glue is drying, assemble the couplings. Insert an M3x25 bolt, with an M3 washer, through each of the two side holes on each coupling. Put an M3 washer and M3 nut on the other end. Do not tighten yet.

- Note: The M3x25 bolts are a little too long for the couplings, and restrict the vertical movement of the x-chassis, or interfere with the z-axis smooth bars. Either use smaller bolts (M3x20), or cut the M3x25's to size. (Doesn't seem to be an issue on my build, but smaller bolts are better.)

- Once the glue has dried, slide the X axis assembly to the top of the Z axis smooth rod, supporting it from underneath somewhere near the middle of the x-axis smooth rods to hold it up. This is important because only the bottom ends of the Z axis smooth rods are adjustable (in the next step). Tighten the M3x10 screws on the bottom of the x-end-motor part.

- Slide the X axis assembly to the bottom of the Z axis smooth rod. If you feel the bushings binding, jog the bar clamps on both sides of the Z axis until the X axis assembly can travel the full length of the Z axis with little resistance.

- Insert an M8 nut from below into the bottom of the hexagonal channels on the x-end-motor and x-end-idler parts.

- (optional) Insert a spring into the top of the hexagonal channels of each x-end part. Insert an M8 nut on top of each spring.

- Thread one end of the 210mm threaded rods into each hexagonal channel from above, compressing the top nut and spring if you have them. The threaded rod should turn freely in each channel, and the nuts should stay snugly in place. Turn the rods until about half their length sticks out from the bottom of the parts.

- Place a NEMA 17 motor into each of the two z-motor-holders, shaft down. You may optionally fasten them from underneath with M3x10 bolts and M3 washers.

- Note: You might not want to secure the z-motors if you have wobbling issues with your x-axis. This is especially true if your threaded rods are not straight or your couplings are not aligned. A good trick is to secure the motors with M3x15mm cap screws with 7mm lengths of soft silicone tube between the motor and its holder. This gives a firm but flexible mount.

- Attach the narrower end of a coupling to each of the motor shafts. Do not tighten the nuts on the coupling yet.

- Turn the 210mm threaded rods so that they go upwards and enter the coupling. Screw them as far into the coupling as they will go, but do not use excessive force.

- Carefully tighten the M3 nuts on both couplings.

- Turn both threaded rods so that the x axis moves up. Make sure the couplings are supporting the weight. If the Z axis rods are hard to turn, or one is a lot harder to turn than the other, you will need to clean the inside of the spring track. The best way I have found to do this is put a nut on the end of a long scrap piece of threaded rod. Heat the nut up on your stove on high, then take the nut and run it up and down the inside of the hexagonal channel until the walls are smooth, and the channel is a little bigger than the nut that goes in it. This should loosen up the hole enough that once reassembled the trouble side travels smoothly.

- Place a spirit level on the x-axis smooth rods. Turn the threaded rod on one side only until the x axis is level. Your Z axis is complete.

Installing the X Carriage

Parts Required

- 1 RP x-carriage

- 1 RP pulley

- 2 RP belt clamps

- 4 PLA bushings

- 1 900mm×5mm T5 pitch timing belt

- 2 M4 nuts

- 2 M4×20 bolts

- 2 M4 washers

- 5 M3 nuts

- 1 M3 grub screw

- 4 M3×10 bolts

- 4 M3×25 bolts

- 8 M3 washers

- 1 Extruder

- 1 NEMA17 stepper motor

Instructions

- Ensure that the hole in the center of the pulley matches your motor shaft (it should slide on and fit very snugly). If it is too tight to fit, drill it out.

- Insert an M3 nut into the rectangular slot on the pulley bottom. You may need to widen the slot slightly to do this. Make sure that the center of the nut is aligned with the channel on the side of the pulley rim.

- Once you are satisfied with the position of the nut, insert an M3 grub screw into the channel on the rim of the hub. Tighten it until you see the end of the screw inside the center hole. Then unscrew it enough to slide the pulley onto the motor shaft.

- Slide the pulley onto the motor shaft so that the rim comes onto the shaft last. Leave 1mm or so of shaft between the pulley and the motor body. Tighten the grub screw.

- Insert the motor into the x-end-motor part so that the motor body is on the front of the machine and the pulley points towards the rear. The pulley teeth and the idler on the opposite side of the X axis should be aligned.

- Fasten the motor using 4 M3×10 bolts and 4 M3 washers. The motor body should now be on top of the x-axis smooth rods. (On my build, the rods do not physically fit between the motor and the base of the x-end-motor part, and 420mm rods are anyway too short to extend the full length of the motor. Instead, I have them stopping beside the motor. I guess this gives less support to the motor, but is the only option using 420mm rods and the reprapped parts I have.)

- Place 4 PLA bushings on the x-axis smooth rods. Make sure they slide freely.

- Put a blob of glue on the flat side of each bushing.

- Place the x-carriage on top of the bushings, making sure they fit into the channels. The protruding part of the x-carriage with the four nut traps should be on the side of the pulley and idler, pointing towards the rear of the machine.

- Wait for the glue to dry.

- Once the glue has dried, make sure the carriage can slide along the rods freely from end to end. Turn the entire frame around so that the rear of the machine faces towards you.

- Put an M3 washer on each of two M3×25 bolts. Thread them through the holes of one belt-clamp. Repeat for the second belt-clamp. (note - we had trouble with the M3x25 bolts hitting the smooth rods, so we used one M3x10 and one M3x25 bolt on each belt clamp)

- Loosely attach one of the belt clamps to the carriage. Thread the two bolts through the holes in the carriage and attach nuts to them. Make sure there is enough space for the belt to slide between the clamp and the carriage. Repeat for the other clamp.

- Slide one end of the belt through the left clamp, toothed side up. Pull several centimeters through, then tighten the clamp.

- Run the belt over the 608 bearing and the motor pulley, then thread it through the other clamp, toothed side up. The belt should now form an elongated loop with the teeth on the inside of the loop. Pull the belt tight and tighten the second clamp.

- Verify that the belt tension is right. Turning the motor pulley by hand should make the carriage move. The carriage should move freely along the entire length of the axis.

- Use two M4×20 bolts with two M4 washers and two M4 nuts to mount the extruder on the x-carriage.

Tips for assembling Wade's extruder and Arcol's hot end

- DON'T MOUNT THE MOTOR AND THE BIG GEAR. Wait till its written here in tips.

- Look at Wade assembly manual Wade's Geared Extruder

- Prepare big wheel with hobbed bolt. Test with filament in fillament path if it matches the hobbed part of wade bolt. Prepare pulley on motor.

- Assemble the long bolts for idler and the bearings. Check how bolts is lining the filament path and other stuff.

- Mount the hotend to the Wade.

- Mount the Wade to the x-carriage.

- Mount the belt on the side where the motor will be.

- Assemble the motor to Wade. Dont use washer on two bolts nearest the big gear. Preferably use low profile screws. Also dont tighten these two screw too much, you can later slide the motor without taking out the big gear.

- Add the hobbed bolt with gear.

- Add the idler.

Attaching the Print Bed

Parts Required

- 1 225x225mm print top plate

- 4 M3x40 bolts

- 4 ballpoint pen springs

- 8 M3 nuts (optionally nyloc)

- 16 M3 washers

Instructions

- If you have a heated build platform, install it on the print top plate at this point. Cover your top plate or build platform with whatever your build surface material will be (Kapton, blue tape, etc.)

- Put a washer on each of the four M3x40 bolts.

- Thread a bolt into the 4 holes closest to the middle of the print top plate.

- Put an M3 washer ,a ballpoint pen spring, then tread a nut just 1mm onto the bolt. (Do not tighten. This nut is only there to hold the springs in place.)

- Carefully place the print top plate on top of the print bottom plate. Make sure each bolt goes through one of the holes in the print bottom plate.

- Put an M3 washer and nut on the end of each of the bolts. (under the print bottom plate)

- Level the bed. To do this, put a spirit level (bullseye surface levels also work well) on top of the bed and adjust the nuts of each of the M3 bolts until the spirit level shows the bed is level. Use the top nut to adjust the height and the bottom nut to fix it. If you have a heated build platform, put the spirit level on the platform. Once done, tighten all nuts.

Wiring the electronics

Parts Required

- 1 Electronics setup RepRap Interface Standard #RIS 1 compatible or anything else compatible)

- 3 endstops

- 3 RP endstop holders

- 3 M3x25 bolts

- 6 M3 washers

- 3 M3 nuts

- A lot of cable ties

Instructions

If you are new to electronics, you may find the Arduino Tutorials on Adafruit quite useful.

- There are various electronics configurations out there (see Alternative Electronics). Regardless of what electronics you have, you should have at least three stepper drivers, ideally four. Those are either integrated on the board or separate modules. Identify the motor connections for X, Y, Z and the extruder stepper (E on some setups). Also identify the connections for the heated bed (if you have one), the extruder heater connection, the extruder and heated bed thermistors, and the X, Y and Z MIN endstop connections.

- Screw or glue your endstops (opto or microswitch) to the long side of the three endstop holders.

- If you are using opto endstops, you will need to make three opto flags. These are long, thin strips of some easily formable, opaque material, for example metal sheet from drink cans. If you are using microswitch endstops, you can skip this step. Take an empty drink can and cut three 10mmx30mm pieces from from it. These will be your optoflags.

- The goal will be to place the endstops at the 0 coordinate for each axis. (x - furthest left, y - closest to the front, z - placed to ensure the printhead can get very close but not touch the printbed). Facing the front of the machine, place one on the left z smooth rod below the x axis. Place one on the far left of the rear x axis smooth rod. Place the third one on the right y axis smooth rod behind the print bottom plate.

- Put an M3 washer on an M3x25 bolt and thread it through each endstop holder, and put a washer and M3 nut on the other side. Do not tighten these nuts yet.

- If you are using opto endstops, glue an optoflag onto the left side of the x-carriage, the bottom of the x-motor-bracket (pointing down) and the print bottom plate, so that they go through the gap in the optoswitch as the axis slides.

- You now need to determine the limits of each axis. With the extruder/hotend installed, slide the X carriage left until the nozzle is 10mm in from the left edge of the print bottom plate. Reposition the endstop so that the opto/switch is engaged in this position. If your optoflag is too long, trim it until it just barely triggers the endstop when the nozzle is in this position. Tighten the nut on the X endstop holder, being careful not to move it.

- Slide the print bottom plate backwards until the nozzle is about 42mm (equivalent is 1-21/32") in from the front edge of the print bottom plate. Reposition the endstop so that it engages when the print bottom plate is in this position. Tighten the nut on the Y endstop holder, being careful not to move it.

- Adjust the Z endstop so that it is triggered when the Z axis moves downwards until the extruder nozzle is just barely above the bed. Tighten the nut on the Z endstop holder, being careful not to move it.

- Decide where your electronics will live. Mount these in place first; this will allow you to route the cables more easily.

- Slide the X carriage as far away from the electronics as possible.

- Route the cables from each of the endstops along the frame to the electronics board. Plug each one into the appropriate connector. For the X endstop, leave enough slack in the cable to allow the X axis to move along the Z all the way up and down the frame. Make sure none of the wires interfere with the movement of the axes. Use cable ties to secure the wires to the frame.

- Splice the Z motor wires together in parallel. If the motors are identical, join each wire with the wire of the same color, and then attach them to the connector that matches your electronics. Route the wires along the frame to your electronics board, and attach them to the Z-driver connector. Use cable ties to secure the wires to the frame.

Note: in some configurations (example: 12V Power supply, RAMPS and SY42STH47-1684B stepper motors), connecting the motors in series has been verified to provide significantly improved performance in comparison to parallel wiring. That is (for that particular motor and using Pololu/StepStick phase designations):

1B -- black -- motor1 --green -- black -- motor2 -- green -- 1A 2A -- red -- motor 1 -- blue -- red -- motor2 -- blue -- 2B

The general point is: coil 1 in motor 1 is wired in series with coil 1 in motor 2, etc. Check your particular motor spec sheets for wire colors, or in default of it, identify the phases with a multimeter. We need more information about the performance obtained with other stepper motors and drivers, please report your findings in this forum thread

- Attach the Y motor wires to the connector that matches the electronics, route them along the frame (making sure they don't interfere with the Y-axis movement) and attach them to your electronics at the Y-driver connector. Use cable ties to secure the wires to the frame.

- Attach the X motor wires to the connector that matches the electronics, route them along the frame and attach them to your electronics at the X-driver connector. Leave enough slack for the X-axis to move all the way up and down the Z axis without getting caught on the wires. Use cable ties to secure the wires to the frame.

- Leaving enough slack so that the wires don't get stretched even when the X carriage is furthest away from the electronics, route the extruder motor, heater, and thermistor wires along the frame, to the electronics. Keep careful track of which wire is which. Color-coding is recommended. If your wires are not different colors, attach labels to the ends. Attach connectors to the wires to match your electronics and plug them into your electronics board. The stepper connection goes into the EXTRUDER/E connector. Use cable ties to secure the wires to the frame.

- Move the X and Y axes all the way in each direction, and check that no wires interfere with movement. Once done, slide each axis to approximately the middle of its range.

- Get a piece of paper, and write "X, Y, Z, E" on it.

- Plug in the power and USB connections to the electronics. From this point on, if ANYTHING acts strange, switch off power first, and figure it out later. This is extremely important!

- Connect to the electronics from a computer using repsnapper, reprap host, or replicatorg.

- Stand in front of the machine. In the software, tell the X axis to move forward (positive) by 10mm. If it moves to the RIGHT, write "OK" under X on your paper. If it moves to the LEFT, write "REV" under X. If it does not move write "NO" under it.

- Tell the Y axis to move forward (positive) by 10mm. If it moves FORWARD (towards you), write "OK" under Y. If it moves BACKWARD (away from you), write "REV" under Y. If the axis does not move, write "NO" under Y on your paper.

- Tell the Z axis to move forward (positive) by 10mm. If it moves UP, write "OK" under Z. If it moves DOWN, write "REV" under Z. If the axis does not move, write "NO" under Z on your paper.

- Tell the extruder to move forward (positive). If it moves in the direction that would push filament into , the nozzle, write "OK" under E. If it moves in the opposite direction, write "REV" under E. If the axis does not move, write "NO" under E on your paper.

- Close the software and switch off the power to the machine!

- For each axis that is labeled "REV", unplug its connector from the electronics, turn it by 180 degrees, and plug it in again. If the connector is polarized (can only be plugged in one way), you might need to reconnect the wires to the connector.

- For each axis that is labeled "NO", make sure its connector is wired to the motor, and the connector is seated properly.

- Repeat the test until all axes are labeled "OK". Now tell the X and Y axes to home. They should move until they reach their endstops, then stop.

Firmware Calibration

Calibration will ensure your motors are moving the correct distance each time they are told to move. An uncalibrated print can print stretched objects or a messy pile of plastic. It's best to calculate the exact X, Y, Z, and extruder values for your printer based on known parameters. Avoid measurements, as these are prone to error.

- Formula for #define x_steps_per_mm = y_steps_per_mm = <math>Steps \cdot Microstepping^{-1} \over BeltPitch \cdot PulleyTeeth</math>

- Formula for #define z_steps_per_mm = <math>Steps \cdot Microstepping^{-1} \over Z_d</math>

- Formula for #define e_steps_per_mm = <math>Steps \cdot Microstepping^{-1} \cdot ERatio \over \pi \cdot BoltDiameter</math>

where:

- Steps = Number of motor steps per one revolution (200 for 1.8 degree, 400 for 0.9 degree motor, etc.)

- Microstepping = Microstepping ratio of controller (1/8 for Gen6, 1/16 for Pololu, etc.)

- BeltPitch = Distance in millimeters between teeth of belt (5.00mm for T5, 5.08mm for XL, etc.)

- PulleyTeeth = Number of teeth on the motor pulley gear (default is 8 teeth for T5 gears; XL gears may use 10)

- <math>Z_d</math> = Distance in millimeters between threads of Z rods (1.25mm for M8)

- ERatio = Gear ratio for extruder gears (Wade's Extruder: 39/11, Accessible Wade's by Greg Frost: 43/10, Adrian's Extruder: 59/11, etc.)

- BoltDiameter = Diameter of hobbed bolt in millimeters, measured at hobbed section

Note: Formula for extruder steps assumes use of Skeinforge 40+

- Pre-calculated #define z_steps_per_mm:

- For 5/16-18 rod lead screws set it to 1133.858 for 1/8 and 2267.716 for 1/16 stepping.

- For 5/16-24 rod lead screws set it to 1512.287 for 1/8 and 3024.575 for 1/16 stepping.

- For M8 rod lead screws set it to 1280 for 1/8 and 2560 for 1/16 stepping.