StevesExtruder

Release status: working

| Description | 3D Printer Drive Unit with Hot End

|

| License | |

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | |

| External Link |

Steve's Extruder and Hot End

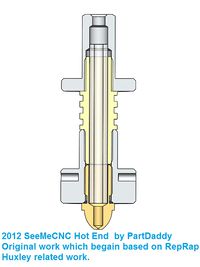

Current Hot End Photos

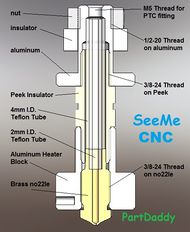

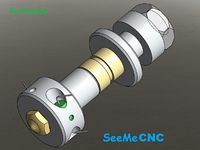

This hot end design is used on the Rostock MAX by SeeMeCNC and the Seemecnc h1 by SeeMeCNC. It is useful for adapting to many other printers as well. It can be configured for direct drive or bowden, with adapters for the PTC fittings for use with bowden drives

Source files for this current version

File:RostockMAX HOTEND OF JAN 15 2013.zip

History

Development began October, 2011. The Steves Extruder was created to be tough, versatile, and provide consistent extrusion rates. Plastic injection molded parts were initially ABS, then changed to Nylon for more durability. During SeeMeCNC's first H-1 3D printer indiegogo campaign in 2011, contributors gave live feedback as PartDaddy designed live on ustream. Many contributors gave input, like Dave S of WA state, regarding o-ring springs, and another contributor asked if it could do both 1.75mm and 3mm filaments. So the drive rollers are turned with both size grooves.

PartDaddy preferred both drive rollers be driven. The gear train was designed so it would be possible for someone to print. A NEMA 11 through NEMA 17 stepper will work with this design. Four 3mm x 10mmL pan head machine screws are recommended.

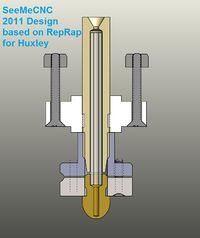

Legacy (Older Versions) Designs

Our First hotend, sold with our H1 kits, had a 2 piece lower section, with a steel plate that the nozzle threaded into. Alu. proved to be more reactive to temps, so we went with the one piece designs now used

Our second hotend, which we still use some parts today on. Features a one pc aluminum lower, and an updated nozzle design