Strong Nozzle

Release status: working

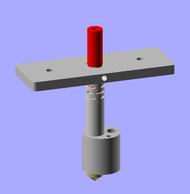

| Description | Strong Nozzle based on stainless steel cool end. Main goals - robust, passively cooled, easy to build hotend.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

Contents

Introduction

Advantages

In comparison with existing solution:

- Nearly unbreakable design

- No leakeages

- No active cooling needed

- Low thermal conductivity towards extruder

- Flexibility because of "spring like" stainless steel cool end

- Easy in maintenance, quick attach/detach from extruder

- Easy positioning, perpendicular by design

Disadvantages

BOM

Version 1

| Quantity | Part Number | Part Name | Details |

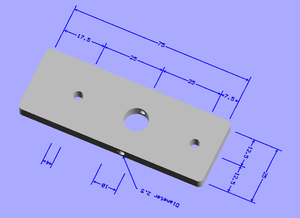

| 1 | 1 | Holder | Alloy plate 75mmx25mmx5mm |

| 1 | 2 | PTFE rod | 50mm long PTFE rod, diameter 8mm |

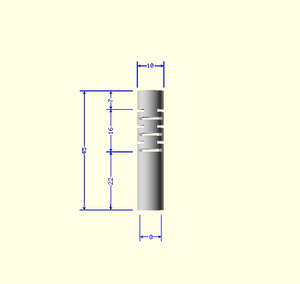

| 1 | 3 | Stainles steel pipe | 45mm long stainles steel pipe, outer diameter 10mm, inner diameter 8mm |

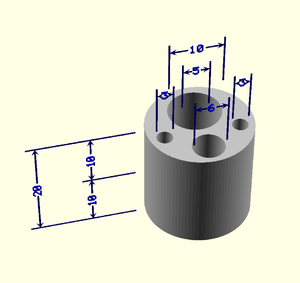

| 1 | 4 | Alloy rod | 20mm long alloy rod, diameter 20mm |

| 1 | 5 | Termistor | 100KOhm, diameted 2mm |

| 1 | 6 | Resistor | 3.3-5.6Ohm wire reistor, length 17mm, diameter 5.5mm, max temperature 360c |

| 1 | 7 | Allo threaded rod | Length 15mm, thread m6 |

| 1 | 8 | Cap nut | Brass M6 Cap nut |

| 2 | 9 | M3 screw | Length 5mm, thread M3 |

| 2 | 10 | Silicone cable 20AWG | Length 200mm, 20AWG |

| 2 | 11 | Silicone cable 25AWG | Length 200mm, 25AWG |

| 1 | 12 | Loctite 620 Retainer | Temperature range: -55°C to +230°C, 4 drops, media:Loctite_620.pdf |

| 1 | 13 | M3 grub screw | Length 3mm |

Manual

Version 1

Tools

| Tool Number | Tool Name |

| 1 | 2.5mm HSS drill bit |

| 2 | 10mm HSS drill bit |

| 3 | 4mm HSS drill bit |

| 4 | M3 hand thread cutting tool |

| 5 | Hand Saw For Metal Cutting |

| 6 | Flat file |

| 7 | 3.2mm HSS drill bit |

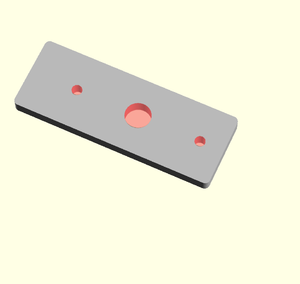

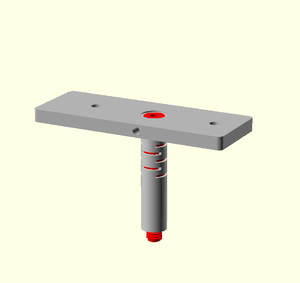

Holder

- Prepare pice of alloy plate [Part 1], by cutting it [Tool 5].

- Drill two 4mm holes [Tool 3] - see red marked holed below

- Drill 10mm [Tool 2] hole in the center - see red marked holed below

- Polish surface with flat file [Tool 6]

Drill points

Dimentions

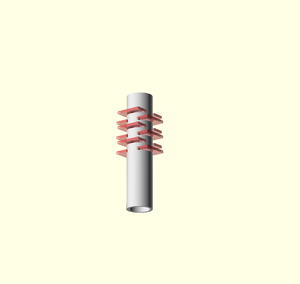

Cold end

- Cut Stainles steel pipe to required length [ Part 3] by tool [Tool 5]

- Make low temperature transition zone by crosswise cutting of pipe

- Glue colend and holder by temperature resistant, adhesive glue [Part 12]

- Drill 2.5mm [Tool 1] hole and make a M3 thread using hand thread cutting tool [Tool 4]

- Take two M3 screws [Part 9] and check if they suits properly

Dimentions

How to cut pipe

How to glue colend and holder

How to drill holder

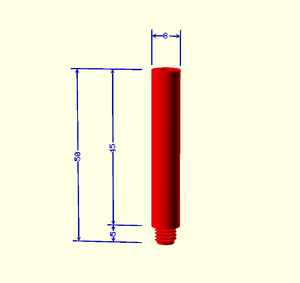

PTFE insert

- Cut PTFE rod [Part 2] to required length by tool [Tool 5]

- Make 5mm long M6 outer thread at the end of PTFE pipe

- Drill hole 3.2mm [ Tool 7] in PTFE rod

Dimentions

How to mount PTFE insert

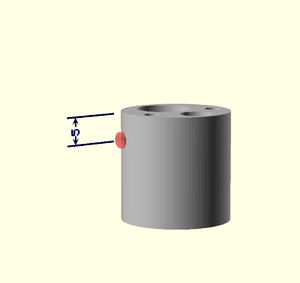

Heater block

Dimentions

How to drill mount hole

Nozzle

DYI Brass M6 Cap nut nozzle

Commercial nozzle from ebay

Temperature sensor

Most of hi temperature NTC termistors are like this below:

Heater

Insert 3.3-5.6Ohm wire reistor [Part 6] in to 6mm hole, connect silicone wires to each end of cable [Part 6]. The simplest way is just to stuff silicon cable on resistor wire. One cable you have on the top, to have second one, bend and put it in to 3mm hole.

Optionally yo can just buy off the helf heater 16 or 20mm long, 6mm diameter, like this:

Off the shelf heater.

Testing

Examples

Photos

Hotend holder

Heater block

Cold end with holder and ptfe insert

Holder, cool end and heater block

Assembled hotend, silicon coating

Assembled hotend in version 1.0, cables, heater and termistor in place

Extruder gears printed during tests

Video

FAQ

Authors

- 3DMakers.pl

- Pawel Ratanczuk,

- Grzegorz Pietrusiak