TRap

Release status: experimental

| Description | Documentation of TRap development

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | |

| External Link |

The TRap will be an alternate mechanical structure for the reprap project. Team TRap intends to make it an entry in the Kartik M. Gada Personal Manufacturing Prize. Before I go any further, I want to thank Team Columbus: I have used Isaac's basic layout for this page.

Contents

Overview

The Gada Prize

- Main article: Gada Prize

The main requirements of the Gada Prize are:

- Print at least three different materials, including one that is usefully electrically conductive.

- Demonstrate the ability to print electronic circuit boards.

- Any print beds must be of a material which may be reused with minimal refurbishment for at least 20 print cycles.

- Maintain a total materials and parts cost under $200.

- 90% of the volume of the device's components shall be printed.

- Demonstrate a build volume greater than 300mm[11.81in] x 300mm[11.81in] x 100mm[3.94in].

- The capacity to print a full set of components for a complete replica of itself within 10 days unattended save for clearing no more than one printer head jam.

- The ability to print autonomously without a PC attached.

- Uses no more than 60 watts of electrical power.

Current Status

I am currently brainstorming various ideas and configurations for use in the TRap.

Current Challenges

- I need a couple of team members. I could use a builder and a control person/programmer, but I don't think I'd turn down help from any interested party.

TRap Specifications

The table below outlines the specifications of the machine.

| Metric[Imperial] | |

|---|---|

| Manufacturer | Anyone |

| Model | TRap |

| Technology | FFF (Fused Filament Fabrication)/Thermoplastic extrusion |

| Price of all materials | TBD |

| Annual Service Cost | TBD |

| Size | 400mm[15.75in] x 400mm[15.75in] x TBDmm[TBDin] |

| Weight | TBDkg[TBDlbs] |

| Build Envelope | 300mm[11.81in] x 300mm[11.81in] x TBDmm[TBDin] |

| Materials | TBD |

| Material Cost | TBD |

| Speed | TBD |

| Accuracy | TBD |

| Finish | TBD |

| Volume of printed parts to replicate | TBD |

Concepts

Concept 1: Modified Delta Style Manipulator

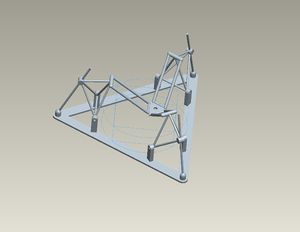

See Workbook entry for September 03. This system is based on "Delta" pick and place robots, but some modifications have been made: the servos are used in prismatic joints, rather than revolute ones. This allows for much more precision (perhaps too much) at the cost of speed. The exact trade-off can be adjusted by altering the tetrahedron design, the axis design, and several other variables. A second variation from "traditional designs" is the use of the tetrahedra to move the servos as low as possible in the design. This eliminates the need for extensive superstructure.

A point of note: I am not the first person to try to design a delta style reprap. I spent some time poking around on the internet to find any prior art, and it looks like Helium Frog (Helium Frog Delta Robot) and Viktor, and reinoud70 (Delta) have built WORKING versions before I even started to imagine the possibilities. A few thoughts: All of these models use extensive support structures that enclose the build envelope, and use some parts of which are much larger than the available build envelope. I hope to avoid this with my design. (While the base plate is large, it will be able to be assembled in pieces, and needs only a flat surface to rest on.) What they have all done, that I am really worried about needing to do myself, is figure out control schemes! Good work! I hope I can do as well.

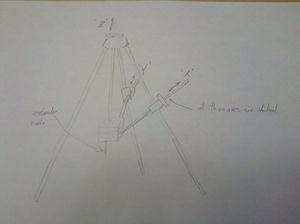

Concept 2: Pyramidal Pendulum Manipulator

This was loaded into the workbook on September 04. At this point, I do not have a good structural sketch, just a poor pencil drawing. (Sorry!) This concept has two major issues: First the extruder platform tilts during use. While this can probably be corrected with clever use of extra arms and universal joints (something like a parallelogram 4-bar linkage), I still need to work out the details. The second problem is that this design requires more extensive structure, including parts that are longer than the build envelope. This means purchased parts, which cut into both my budget and percentage of printed parts. Currently I think that Concept 1 addresses both these issues adequately. All that said, this design has an advantage in that it requires a relatively small volume of printed parts, and is scalable simply by lengthening the axes and legs!

Provenance: I have not done any research yet to see if others have already pursued this idea. If you (the reader) knows of something, please let me know!

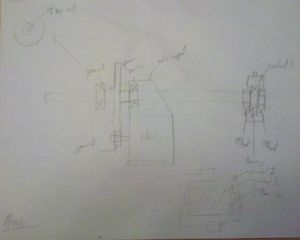

Concept 3: Prismatic Axis

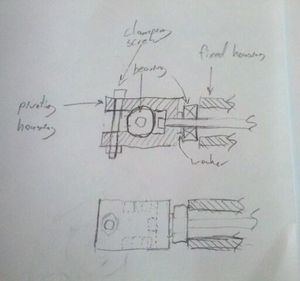

Concept 4: Reprap-able Universal Joint for Delta-Style Manipulator

Design Philosophy

- The TRap will make use of a parallel manipulator

- The number of unique parts shall be kept to a minimum

- Parts shall be made as simple as possible

- Identical parts will be used wherever possible

- Orthogonality shall be preserved wherever possible

- Non printed parts shall be "Off-the-Shelf" (OTS) whenever possible

- Modifications to OTS parts should be avoided wherever possible.

- Substitution of similar OTS parts should require a minimum number of changes to the design (i.e. a change of bearing size)

Nomenclature

Key Concepts

Structure

- Concept 1 and 2 are out! see work log below. Currently, concept 1 is my preferred design.

Like the Mendel, the TRap is composed of a print bed, motors and associated electronics, an extruder tool head, a drive train, and control software.

Print Bed

- Many options here: This could be whatever flat surface that the TRap is sitting on. There is also plenty of space to add a custom bed, perhaps a heated one.

The print bed has 2 functions:

- to support the part currently being printed

- to hold the part and the bottom 3 hinges of each of the 3 axes in a fixed and rigid position relative to each other. (the "base plate")

Extruder

- TBD, possibly a Bowden extruder due to the light weight. This allows all 4 motors to rest on "ground", so the structure does not need to be strong enough to hold up heavy stepper motors, much less strong enough to move them around rapidly and precisely.

- Eventually, a three material extruder needs to be developed. (Not my problem, I hope . . .)

motors and associated electronics

The same stepper motors used in Darwin seem more than adequate. Heavier is better, as it will act to anchor each corner of the design (concept 1).

Off-the-shelf standard RepRap electronics appear to be adequate for the first prototype. Hopefully the TRap will be able to use one or more of the Automated Circuitry Making techniques to make its own circuit boards.

Axes

The drive train is biggest difference between TRap and the earlier RepRap Mendel design. All other differences are in support of this one change.

- 3 Identical Axes assemblies

- Threaded Rod ~35 cm [13.8 in] long(3) - Diameter not yet determined, but any size from M4 up should be fine. Compressive loads should be very low, so buckling should not be a problem.

- Ball Bearings (~42) - only one size needed. The following is an attempt to estimate the number of bearings needed for the design (Concept 1)

- 6 Arms * 2 joints per arm * 2 bearings per joint = 24

- 3 Tetrahedra * 2 bearings each = 6 (Located at the revolute joint between the tetrahedron and the base plate, one bearing on each side)

- 3 Motorized Axes * 4 bearings each = 12 (Each axis is connected to both the base plate and a tetrahedron with a revolute joint, which require 2 bearings each.)

- Screws (~60) - It may be possible to use only one or maybe two screw sizes. Something in the 20 mm range should do for most situations

- Washers (~144)

- Nuts (~80)

- Three nuts to match the threaded rod

- The rest are for the screws

- ???

Control software

- TBD, this will not be a trivial problem

Workbook

In order to keep this page reasonably short I've moved the workbook to another page. This page (TRap) will reflect the latest information available, and this section will be updated with a brief summary of what has happened each month.

2010 September

Summary: Created This page. Basic concepts uploaded. Covers main structure, axes, and universal joints.

General Notes

In accordance with the official Gada Prize rules regarding documentation and transparency - as interpreted by the RepRap Core Team and others - all documentation for this project will take place here in this wiki. If there happen to be any "Other Spaces" out there that have documentation for this project, then such information is posted there only after it is posted here.

- The following notes help to keep this workbook in a neat and orderly condition and shall be generally adhered to throughout all levels of documentation.

- All dimension and temperature nomenclature shall include both SI and Imperial units. SI units shall be first followed by Imperial units in brackets. Examples: 100mm[3.94in] and 40°C[104°F]