TZExtruderTip

Huxley extruder tip (TechZone version)

--AlexRa 17:42, 20 February 2011 (UTC): As it is, the construction of hot tip in TechZone's Huxley kit simply doesn't work. The first time I tried it, the tip was pushed out of the PTFE holder, destroying the threading in PTFE. That was with ABS, at about 240C. Lambert from TZC kindly sent me a replacement tip kit, and as soon as I tried it, this time with PLA at ~180C, it got pushed out as well (see the photo). Apparently, the filament melts along the whole tip and liquid plastic gets into the threads, working as lubricant.

Obviously, PTFE is not strong enough to withstand the pressure. As Lambert suggested, an easy solution would be to put some woodscrews into the PTFE block, so that the sharp end of the screw pushes into the brass tip. A better solution would be to cut a groove in the tip and put some pins through the PTFE locking into the groove:

Extruder tip (AlexRa's version, Mark I)

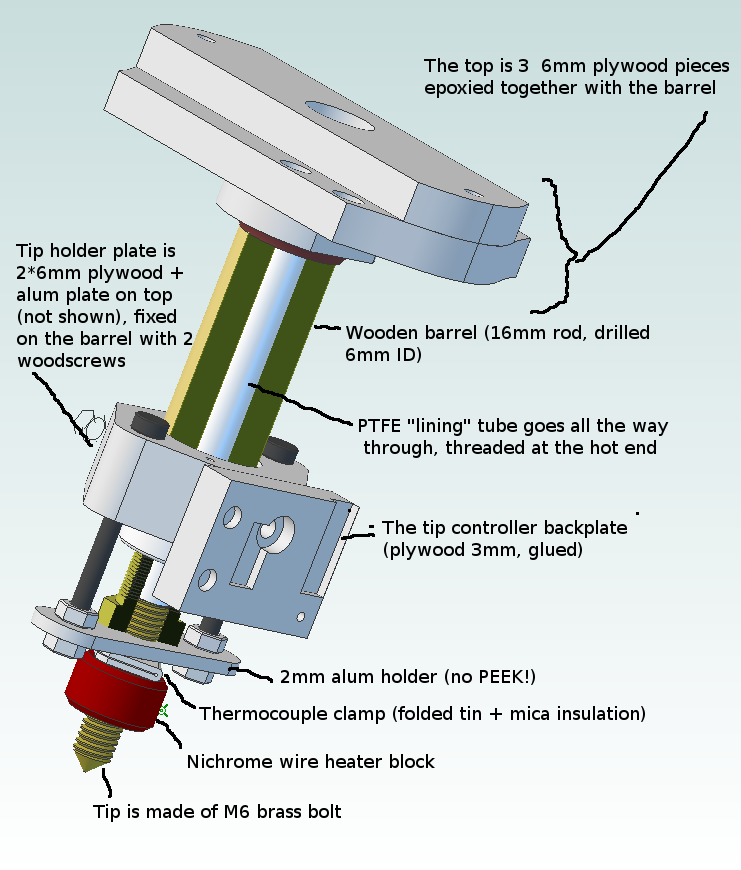

I've ended up making my own extruder tip assembly for my Huxley (TechZone's version) and with that finally was able to print out something resembling a properly reprapped part.

Instructions for building the extruder assembly can be found here: Plywood Tip Assembly for Huxley

Extruder tip (AlexRa's version, Mark II)

Another somewhat troublesome part of TechZone's Huxley design is the X-caret, specifically the bronze sliding insert which doesn't provide as smooth motion as ball bearings would. I'm considering a non-RP X-caret made of plywood, with ball bearings fixed on some alum profiles, and a better integrated extruder tip. With no plastic anywhere close to the extruder, the whole X assembly can be made much more compact (adding height to the printing volume) and precise.