ThermoplastExtruder 2 0 BoM

Contents

ThermoplastExtruder Version 2.0 Bill of Materials

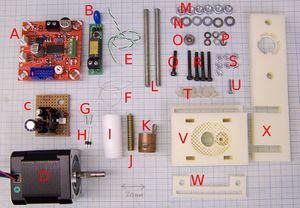

All the parts

Bill of Materials

Select Thermoplast Extruder v2.0 at the bottom of the spreadsheet:

<iframe width='100%' height='600' frameborder='0' src='http://spreadsheets.google.com/ccc?key=pmEMxYRcQzzATwbOb71BmGA'></iframe>

Notes

The NEMA 17 stepping motor should ideally be able to give a slow-speed torque of 0.25 Nm, though lower values will work. It should be bipolar. If you can, get one with a splined shaft so that shaft will grip the polymer being extruded. There are other solutions if you can't get splined, though - see this section of the extruder's instructions.

You can build this extruder with either a high-temperature thermistor for temperature measurement or with a thermocouple (which is what the parts list assumes). For a thermistor get a 100 Kohm thermistor that will go up to 250oC (this will usually be a glass bead type) instead of the K-type thermocouple, and get the RepRap thermistor interface PCB instead of the thermocouple PCB.

The thermal barrier is shown as being 15mm diameter PTFE. Sometimes you can get 16mm instead of 15mm - that's fine too, though you may have to put it in an electric drill chuck and run a little sandpaper against it to get it to fit (I ordered 16 mm and it came as 15.4 mm, so - who knows?). You can also use PEEK rod instead of PTFE, which is tougher and easier to machine, but not such a good thermal insulator.

The picture shows uninsulated nichrome heater wire (F). This will work, but it is more fiddly than glass-fiber-insulated nichrome; get that if you can.

The PWM circuit in the picture is not the standard one - I wired up a single channel of the standard circuit on stripboard when I made the prototype as I did not have a RepRap PWM PCB to hand, and it is that stripboard circuit that is shown.

-- Main.AdrianBowyer - 02 Mar 2009