User:Bryanandaimee

Who I Am

Hello, my name is Bryan Jackson. I am a newcomer to the wonderful world of 3d printing. I purchased my Makerbot in October of 2010 and have been printing steadily since then in my "spare" time. I have printed 3 sets of Prusa mendels on my Makerbot so far. One I gave to a coworker, (see frankenprusa below), one I am building for myself and the third was a Holiday Prusa that I gave to a friend at the seattle robotics society during the Holiday Prusa Contest. Details of these projects are documented below.

You can find my thingiverse profile here.

Besides the Prusa printing, which has taken most of my printer time lately, I am working on a generic and hopefully versatile servo bracket for robotics. I'll be posting it on thingiverse soon.

Update: my Versatile Servo Bracket System is up! My first thing on thingiverse. And it was featured too:) I am still working on adding more parts to enable more and better uses of the system.

I am also planning on designing the printed parts for a quilting frame. I just bought a kit for my wife and built it for Christmas. I liked the design, but there was a lot of jigsaw work and custom cuts. I think it can be done cheaper and easier with 3d printed parts and simple lengths of 2x4 studs.

I have a website called highschoolrobots.com where I post my electronics and robotics ideas for teachers on a limited budget, and here is the family blog. There isn't much geeky stuff on the blog, but there are some posts about the Makerbot.

My Prusa

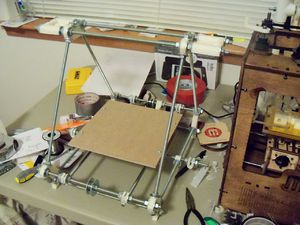

I am building a Prusa Mendel that I have printed out on my recently purchased Makerbot. Why? Because it's there. Do I need two 3d printers when there are billions of people in the world with no 3d printer at all? No. But I want it. As you can see the printer is waiting on installation of motors and electronics. I recently received the motors and I am working on getting them installed and aligning everything. After that I'll be working on the electronics.

Of course I am hoping to win the holiday prusa contest and get a free set of electronics:) But if not I guess I can save my pennies and get a set of electronics eventually.

I could use the electronics off my MakerBot of course, but I'd rather not be out of the 3d printing game for however long it would take to get them running on the Prusa. Actually I am kind of surprised at the many different ideas floating around in my head for printing. When I bought the MakerBot I didn't know exactly how I would be using it beyond a few robotics projects I had in mind. Since then I have been printing all kinds of stuff from Thingiverse and even let my kids design some Christmas ornaments and printed them out. The uses just keep piling up. When I bought it I considered it a frivolous purchase and only justified it on the basis of supporting my robotics hobby, but I have slowly come to regard the little guy as a very useful tool. I still don't know about "wealth without money", (How much of your quality of life is based on small plastic objects?) but I am constantly being converted to the general usefulness of the 3d printer.

6-19-2011: Well the Prusa is about finished. I etched a couple Gen7 V1.2 boards and I have the axes jogging around. Once I get the extruder hooked up and working I should be about there. Unfortunately I am psychologically incapable of working on just one project at a time, so the Prusa has to compete with my development work on the Test Tube Mendel design I am working on.

Test Tube Mendel

Well what better way to waste time than to design a new variant of the Mendel 3D printer. After building and learning to use my makerbot cupcake and having nearly completed building my first Prusa printer I figured it was time to branch out into fame and fortune by creating my own printer design. It is based on the vinyl tubing vertices shown on thingiverse by Mrkim

The goal of the project is to get the printed parts total print time down to a point that people would be more likely to print a set of parts free for friends than to sell them, and I am hoping to get it down to a point that the printed parts kits will come down to under $50 or less. I don't have a real handle on total print time yet since many parts still aren't designed yet, but I'm hoping for something under 10 hours total print time.

.

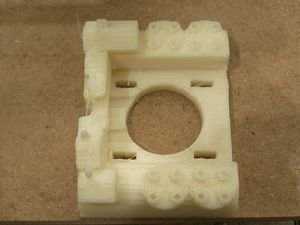

Holiday Prusa Contest

12-18-2010: I got started late printing parts for the holiday Prusa contest, but it was such a cool idea I couldn't help it. I printed the first ten parts without any idea who would be the recipient. There were two guys at work that were interested, but neither one thought they would have time to get the thing built by the contest deadline of Jan 15 2011, so I took the parts to the December Seattle Robotics Societymeeting and found an excited recipient. Look here later for updates as I finish printing parts and he gets started on the build. At left are some of the latest parts I have printed. I'll be sending these over to the recipient soon. On a similar note one of my coworkers will be building the FrankenPrusa described below. He will be out of town and away from his shop for a few weeks, (Shop withdrawl, make it end!) so he wasn't able to participate in the holiday Prusa contest, but he'll build an SAE prusa from my first set of parts (not too pretty:) when he gets the time.

12-25-2010 Just finished printing all the parts. I'm getting the hang of this printing stuff. I haven't had a major problem printing in quite some time (see FrankenPrusa below for an account of my previous failures).

1-6-2011 Happy New Year! As part of my bid to win the hotly contested Holiday Prusa Contest, I am going all out and including all forms of media. Todays entry, a poem.

A Christmas Prusa:

The gift that gives endlessly

spoiled by bad Haiku

1-5-2011 Today, a tour de force: Science Fiction in 65 words.

The Mekarn were coming. Half the fleet was down for repair. Those @#%$ imported firing buttons from Mars kept breaking off at the base. The pride of the first solar system would soon go down in defeat for want of a small plastic part. Earth would once more be subjugated by alien life inimical to all we hold dear. If only there were some way…

1-14-2011 A top ten list for the second to last day of the contest

Top ten reasons I should win the Holiday Prusa Contest

10 Santa told me I deserve it.

9 Electronics will allow me to complete my own Prusa Mendel

8 My kids are cuter than theirs (Are there any other contestants?:)

7 I am the first entrant to the contest

6 Elfyourbot (need I say more?)

5 FrankenPrusa: Recycling and charitable giving in one set of parts

4 Bald is beautiful

3 My rugged good looks (No picture provided)

2 Humility is overrated

1 I want those electronics! (You gotta want it)

1-15-2011 Final contest day update!

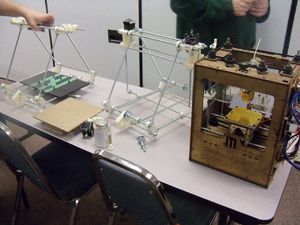

Here is the final progress update before the close of the contest. The picture is of my Makerbot and two of the three Prusa Mendels I have printed on it. One is the holiday Prusa (on the left) the other is an SAE Prusa I am building for myself. The third Prusa I printed is the FrankenPrusa detailed below. As you can see the Holiday Prusa didn't get quite finished, but Doug is well on his way. He has some salvaged steppers from old printers, and most of the other stuff he needs. It's just a matter of finishing the assembly. We met today at the Seattle Roboics Society meeting and compared bots and generally kibitzed about our plans and how we were going to finish the bots. I'll still post updates to this page as the printers get completed.

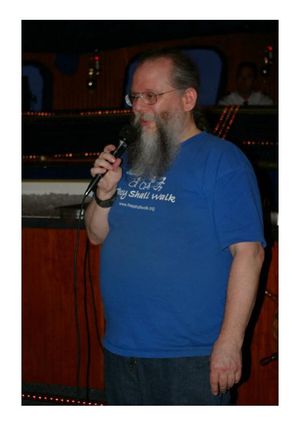

Holiday Prusa Recipient

Doug Bell is a member of the Seattle Robotics Society, the project engineer for TheyShallWalk.org, and a regular technical advisor to local FIRST robotics teams. The printer is being built by Doug and other volunteers at theyshallwalk.org for their use in furtherance of the cause. If you haven't checked out what they are doing over at theyshallwalk.org you really should. It is a wonderful project to design a robotic brace to allow wheelchair bound individuals to walk again. In addition to their web page linked above they have a cool facebook page with lots of pics and links to youtube videos. I had originally assumed that Doug was building the printer for himself, and that it would be used for a variety of purposes. I was mistaken. Here is his clarification and an update on their progress from Doug.

"I received the parts from you on behalf of They Shall Walk, the printer is being built by volunteers at They Shall Walk, and it will belong to They Shall Walk when it is finished.

Since the SRS meeting, we've taken apart an Apple ImageWriter and an ImageWriter II, and I brought three more ImageWriter IIs to They Shall Walk for us to take apart. We plan to use the 1.8 degree stepping motors, perhaps the belts and/or smooth rods, and hopefully the drive electronics as well from them for the 3-D printer. I'm working now to diagram the circuit of the power supply/motor control board from the ImageWriter II.

So far, we've only spent about $36 on the printer, for parts from Lowes'.

Doug"

I am so impressed by these guys. I'm sure lots of people have harvested steppers and belts and such for their Mendel projects before, but I wonder if Doug and his crew are the first to use salvaged printer stepper drivers. They may end up building the least expensive Prusa ever built. Best wishes to Doug and the gang at They Shall Walk.

6-19-2011: Final update. The holiday Prusa was not completed by the contest deadline (or the extended deadline :) and so the contest judges decided not to award the prize. Doug is still working on getting the printer put together and running. Hopefully they will post info on the blog at They Shall Walk as they get it nearer to completion.

FrankenPrusa

I am new to 3D printing, having just recently purchased a MakerBot. My first attempts at printing larger parts were not very pretty. I had so many failed prints of the Prusa frame vertex parts that I decided to try gluing them together to make functional parts. I used ABS glue from the hardware plumbing department and glued and clamped till I had quite a few functional pieces. I even inverted the parts and printed some intentional half prints to match the failed prints from before. A little drilling and sanding and they are quite functional if not beautiful. So what do you call a Prusa Mendel built from pieces of failed dead prints? Why FrankenPrusa of course. The holiday Prusa contest inspired me to find recipients for all this stuff and so in addition to the holiday parts that I am giving to an acquaintance at the SRS (see above), I am also giving frankenparts to a coworker to build in his spare time. I'll try to keep this updated as the projects get underway. The Frankenpart you see at the left was made from 3 different failed prints. It is definitely the most extreme example of part salvage in the FrankenPrusa. The holes still need to be drilled out and the clamping surfaces shaved flat, but I think it will work fine. ABS glue is quite good at gluing ABS parts together.(who knew!)