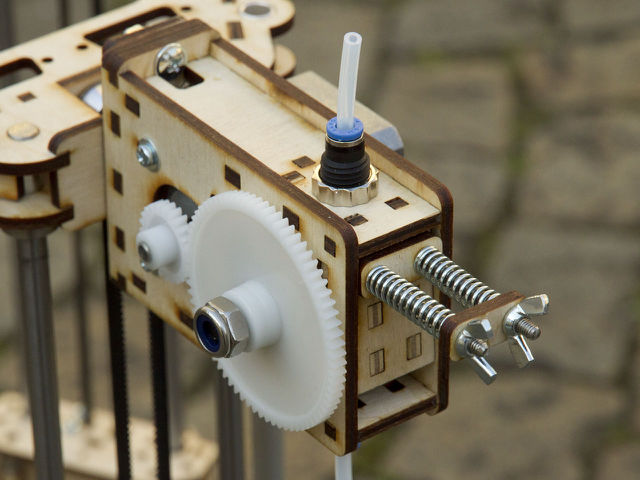

Wood-D Extruder Drive

This page is a development stub. Please enhance this page by adding information, cad files, nice big images, and well structured data!

Release status: working

| Description | Just another wooden bowden extruder for 3D-Delta-Printer (Open Source Project)

|

| License | CC BY-NC-SA 4.0

|

| Author | |

| Contributors | |

| Based-on | [[]]

|

| Categories | |

| CAD Models | CorelDraw / PDF

|

| External Link |

Contents

Description

Wood-D - Just another wooden 3D-Delta-Printer (Open Source Project)

Wood-D Extruder Drive is a simple bowden extruder based on LASER cut plywood or MDF or acrylic for 1.75 mm filament.

Design Objectives

Specifications

| Principle | Bowden extruder like Wade's Geared Extruder | |

| Construction | LASER cut 4mm plywood or MDF (1 piece 102 x 295 mm) | (also acrylic can be used) |

| Drive | Gear driven hobbed bolt with NEMA 17 stepper motor | |

| Filament | for 1.75 mm | (Little redesign for 3 mm) |

| Dimension | 100 x 60 x 32(+Gears) mm |

Features

Based on the LASER cut constructive parts you get a very high precision while easy to assemble.

The plywood parts/puzzle are hold together with key and slots and a little bit of glue. Due to the box design with cross bracing the stiffness is very high.

All non-plywood parts are standard industrial parts you can be bought from online shops or eBay.

Easy assembly - only drive shafts and threaded rods have to be sawed.

Necessary tools: LASER cutter (visit a FabLab/Hackerspace in your area), hand saw and file for metal, screw drivers, gripper, cutter, soldering iron

Parts

Case

LASER cut 4 mm plywood or MDF or acrylic

Drive

Hobbed bolt M8 x 60 (as in Wade's Geared Extruder) OR a hobbed shaft with M8 on both ends.

By now you can even get industrially made shafts of hardened steel.

Gears

Use standard industrial gears OR RepRap printed gears from e.g. Wade's Geared Extruder or Greg's Hinged Extruder or other derived variations

Note: You also find sources for printed gears on thingiverse.com like the High Resolution Herringbone gears for Greg's Wade Reloaded extruder

The effective gear distance can be adjusted between 37.5 and 42.5 mm by sliding the motor.

The different gear types needs different ratio settings in firmware

- Example: Marlin firmware with 6.0 mm effective shaft diameter)

- #define DEFAULT_AXIS_STEPS_PER_UNIT { 80, 80, 80, (200*16) / (6.0*3.14) * XXX }

| Type | Module | Gears | Ratio | Eff. Dist. | Example XXX | Comments |

|---|---|---|---|---|---|---|

| Industrial | 0.8 | 72 / 24 | 3.000 | 38.4 mm | (72/24) | The 72 tooth gear has to be widened from 6 mm to 8 mm or M8 (6.8 mm core) |

| Industrial | 1 | 64 / 12 | 5.333 | 38 mm | (64.0/12.0) | The 12 tooth gear has to be widened from 4 mm to 5 mm for motor shaft |

| Industrial | 1 | 64 / 18 | 3.555 | 41 mm | (64.0/18.0) | Fits as is. |

| RB Wade's Geared Extruder |

? | 39 / 11 | 3.545 | 41.9 mm | (39.0/11.0) | Fits as is. Has hex-bolt-fitting |

| RB Greg's Hinged Extruder or herringbone / fishbone variations |

1.5 | 47 / 9 | 5.444 | 42 mm | (47.0/9.0) | Fits as is. Has hex-bolt-fitting |

For the prototype and tutorial images an industrial type 72/24 was used.

Motor

NEMA 17 stepper motor as usual in RepRap projects

Bill of Materials

| Quantity | Description | Type | Comments | Diagram |

|---|---|---|---|---|

| 1 | 4 mm plywood or MDF or acrylic with min. 102 x 295 mm | LASER | ||

| 1 | Hobbed bolt M8 x 60 (as in Wade's Geared Extruder) | Shop | ||

| ? | Washer M8 | Fastener | distribute to center the hobbed position | |

| 1 | Plastic gear 72 tooth module 0.8 (has to be widened to 8 mm or M8) | Shop | ||

| (1) | Alternative: RepRap big gear 39 tooth from Wade's Geared Extruder | RP |

| |

| 1 | Plastic gear 24 tooth module 0.8 | Shop | ||

| (1) | Alternative: RepRap small gear 11 tooth from Wade's Geared Extruder | RP | | |

| 2 | Ball bearing with flange F608ZZ | Shop | ||

| 1 | Ball bearing 605ZZ | Shop | ||

| 1 | Steel shaft 5 mm with length 34 mm | Shop | recommended: shaft with ground surface | |

| 1 | Steel shaft 5 mm with length 17 mm | Shop | recommended: shaft with ground surface | |

| 2 | Pneumatic bulkhead connector/fitting for 4 mm tube | Shop | ||

| 1 | PTFE (Teflon™) 4/2 mm tube with length about 2x 30 mm | Shop | use same as for connecting the hot end | |

| 2 | Threaded rod M4 with length about 100 mm | Fastener | length depends on spring and nuts | |

| 4 | Nut M4 | Fastener | ||

| 4 | Screw M3 x 8 | Fastener | ||

| 4 | Washer M3 | Fastener | ||

| 2 | Wing nut M4 | Fastener | ||

| (2) | Alternative: knurled nut M4 | Fastener | ||

| (2) | Alternative: nut M4 glued in wooden star knob | LASER | wooden parts for star knob are in new LASER cut files | |

| 2 | Spring 7 x 5.4 X 35 (or similar) | Fastener | nearly any spring with an inner diameter greater than 4 mm | |

| 1 | NEMA 17 stepper motor | Shop | ||

| Casein glue | Misc | for wooden parts | ||

| 2 Component glue (Epoxy) | Misc | for nuts on the threaded rods and the gear on the stepper motor |

Downloads

Design and LASER cut files at GitHub repository github.com/jkDesignDE/Wood-D

Tutorial

Assembling tutorial as image sequence at wood-d.de/tutorials/tutorial-wood-d-extruder-drive

Links

More infos about the Wood-D project on the blog page wood-d.de (German language)