ZemcikO hot end

Release status: working

| Description | This is my plastuder using modified geared end and cheap turned hotend.

|

| License | |

| Author | |

| Contributors | |

| Based-on | |

| Categories | |

| CAD Models | Alibre 3D, pdf 2D drawings

|

| External Link |

Contents

Extruder for Mendel with "complete" documentation

Status:

(v 2.3) - fully working

(v 2.4) - fully working

(v 2.5) - fully working

Be patient please, page is under (permanent) construction.

This page describes evolution of the my extruder for RepRap Mendel. Several months im trying to complete my reprap 3D printer. After many tries, this is what i have now.

1. its relativelly easy to build

2. cheap

3. modular (0.3 0.4 and 0.5mm nozzle)

4. designed in ISO standard

I´ll upload 3d models in Allibre format, 2d drawings in .pdf format (for machined, handmade parts) and stl models (for printed parts).

Special thanks to wade's/ greg's extruder (accesible version) and Mk6 hotend designed by Makerbot and many others.

Before we start, lets have some preview.

Upper part (geared/cold end) is similar for all my versions.

File:Extruder allibre zemciko v1.zip v1 peek holder and no ptfe tubing

File:Zemciko gregs wade extruder v11.7z v1.1 wooden holder no ptfe tubing

Bill of materials

Hot end v 2.3.

Clear PTFE round rod 16mm diameter (about 9euro per meter, u need only +-100mm)

Brass rod 16mm in diameter (20 euro per meter) (u need only +-50mm)

Aluminium rod (diameter 16 for 4euro per meter) (u need only +-30mm)

Steel rod 40x4mm (1euro per meter, u need +-100mm)

1x resistor 6R8 3-4W (5mm diamter, 1,5euro)

1x thermistor 100k 300°C (1,9mm diameter)

wirings 2A.

2x M3x25 nuts + washers

Silicone hi temperature paste for RC model motors COPPER XST 85g (tube for 4euro).

Hot end v 2.5.

Clear PTFE round rod 16mm diameter (about 9euro per meter, u need only +-100mm)

Brass rod 16mm in diameter (20 euro per meter) (u need only +-50mm)

Aluminium rod (diameter 16 for 4euro per meter) (u need only +-30mm) or Aluminium rod 40*4mm (easier to machine both parts of heater block)

Steel rod 40x4mm (1euro per meter, u need +-100mm)

2x resistor 6R8 3-4W (4.2mm diameter, u need "wire" not "metalic" version, 2euro)

1x thermistor 100k 300°C (1,9mm diameter, 1.5euro)

wirings 2A and signal version. (1euro)

2x M3x25 bolts + washers

2x M3x12 bolts + nuts + washers

2x Any type of metalic mechanical cable connectors for heat resistor connection (im using copper parts from inside of connectors..).

(Small lathe, milling machine, tolls etc.)

Hot-end

File:Zemciko-hotend-drawings v1 1.7z 2D dravings in pdf format. Version with wooden holder and no ptfe tubing.

File:Zemciko Hotendtubed v12.7z Hotend with ptfe tube 3/5 v 1.2 Allibre 3D files.

File:Zemciko hotend vykresy v 2 1.7z Hotend made from Al and PTFE v 2.1, 2D drawings.

File:Zemciko alibre 3d v 2 3.7z ZemcikO hotend v 2_3, tested, working well, 3D Alibre model.

File:Zemciko vykresy v 2 3.7z ZemcikO hotend v 2_3, tested, working well, 2D drawings.

File:GWZ24.7z ZemcikO hotend v 2_4, testing, for "prusa type" x axis, 3D Alibre model.

File:Zemciko vykresy v 2 4.7z ZemcikO hotend v 2_4, working, for "prusa type" x axis, 2D drawings.

File:Zemciko-hotend-2-5.zip ZemcikO hotend v 2_5, working, for "prusa type" x axis, aditional 2D drawings (just replaced parts from 2.4).

Geared-end

File:Zemciko-geared-end-machined-drawings.7z 2D drawings in pdf format. Geared end machined parts for v1 and v1.1 extruder.

File:Zemciko wader printed parts.7z STL models from Allibre. Printed parts for v1 and v1.1 extruder.

Geared end is redesigned Greg-Wader version with some modifications.

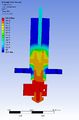

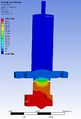

FE simulations

Tests

v 1.1 Its nice, modular and printing. Problem is wit material leaking back into extruder...

v 1.2 PTFE tube should be longer otherwise material can stuck before tube entrance...

v 2.1 Works nice but Al nozzle is too wak and ten to crack during disassembly

v 2.2 Same as 2.1 but brass nozzle. Works fine, until u try to disassembly it, PTFE part with thread is too weak....

v 2.3 Thread was replaced by steel "collar". Look good, works good, can be easilly disassembled, when needed, and printing results are superb.

v 2.4 Redesigned for round type carriage. For original Mendel carriage use v2.3 with v2.4 nozzle. PTFE tube is 5mm shorter, it can by compensated by doubling copper cooler.

v 2.5 Redesigned heater element. Added second copper cooler an fan to x-axis carrriage. 2x more powerfull heater element.

<videoflash type="youtube">4YI4Eap9nR0</videoflash>

My hot-end (v2.5) mounted on reprap sinuhed, printig geared wheel for plastruder (z=43 m=1,5mm).

Features/Bugs

Size of holes for nylock nuts in main extruder body should be decreased (stl model). (nuts are slipping and must be fixed) V 2.3 should use Brass nozzle, instead Al. (Al looks is too "brittle" and can be broken during disassembly). Highly recomemned to use fan on printing head. On all versions (2.3-2.5) u can use, as heater element, mounted one from version 2.5. Its easier to mount/demount, more stable and can warm up much much faster....

U can contact me on [email protected]. --zemciko 09:19, 19 June 2011 (UTC)