Constant high-speed printing

Posted by richrap

|

Constant high-speed printing August 23, 2011 07:26AM |

Registered: 13 years ago Posts: 818 |

Hi Everyone, I’m interested in people’s experiences of high-speed printing, I know speed isn’t everything and I still like to do many things at 25mm/sec but recently I have been experimenting with faster printing and I wanted to get some feedback from others on their experiences before I push it much further. I think I'm achieving 180mm/sec at the moment.

So a few things I hope to test and some questions to have a think about –

Does anyone know what speed Sprinter and the Atmel Mega can actually achieve as a maximum constant print speed?

If you drop to 4x or 8x micro-stepping to free up some processing time can you increase this overall print speed?

If you ask Sprinter/firmware to print at say 300mm/sec will it try to do that or just go as fast as it actually can, and if it can’t achieve the set speed does this mess up the extruder feed/flow.

How can I externally check if it’s actually running at the speed I have set in Skeinforge?

Skeinforge gives me an expected print time; does anyone know how accurate this is to real life? I must say I have never actually checked myself.

If anyone has any feedback on this or any other advice I would really appreciate it.

It would be great if people can list the real top-speed they are achieving? and how?

I can think of loads of other questions about material / filament size pro/con with speed, ideal hobbed bolt spec for speed and stability of heating block temperature, but I don’t want to ask too many questions in one go - even though I just did

Thanks,

Rich.

[richrap.blogspot.com]

So a few things I hope to test and some questions to have a think about –

Does anyone know what speed Sprinter and the Atmel Mega can actually achieve as a maximum constant print speed?

If you drop to 4x or 8x micro-stepping to free up some processing time can you increase this overall print speed?

If you ask Sprinter/firmware to print at say 300mm/sec will it try to do that or just go as fast as it actually can, and if it can’t achieve the set speed does this mess up the extruder feed/flow.

How can I externally check if it’s actually running at the speed I have set in Skeinforge?

Skeinforge gives me an expected print time; does anyone know how accurate this is to real life? I must say I have never actually checked myself.

If anyone has any feedback on this or any other advice I would really appreciate it.

It would be great if people can list the real top-speed they are achieving? and how?

I can think of loads of other questions about material / filament size pro/con with speed, ideal hobbed bolt spec for speed and stability of heating block temperature, but I don’t want to ask too many questions in one go - even though I just did

Thanks,

Rich.

[richrap.blogspot.com]

|

Re: Constant high-speed printing August 23, 2011 09:49AM |

Registered: 12 years ago Posts: 90 |

> Does anyone know what speed Sprinter and the Atmel Mega can actually achieve as a maximum constant print speed?

I print at 150mm/s with 450mm/s travel using Sprinter/Mega on an Ultimaker.. (edit: and not just easy prints, either. this was done at that rate, with perimeter slowed to 50mm/s: [www.thingiverse.com])

Somebody just got the new Marlin (Merlin?) firmware working on his Ultimaker and says: "So far, it's been working fine at prints 0.2 mm layer height; feedrate 300 mm/s; travel 900mm/s" so I guess I'm not really pushing my machine that hard.. [groups.google.com] .

> Skeinforge gives me an expected print time; does anyone know how accurate this is to real life? I must say I have never actually checked myself.

It's accurate as far as adding up the various move commands at different speeds. Sprinter may (will) slow things down at various points to handle acceleration, which will make the print take longer than skeinforge estimated. How much longer depends on how often the firmware slows things down on you.

> How can I externally check if it’s actually running at the speed I have set in Skeinforge?

I don't think you can, unless you want to modify the firmware to report on things like that.

Not sure about the rest of your questions..

Edited 1 time(s). Last edit at 08/23/2011 09:51AM by Dave Durant.

I print at 150mm/s with 450mm/s travel using Sprinter/Mega on an Ultimaker.. (edit: and not just easy prints, either. this was done at that rate, with perimeter slowed to 50mm/s: [www.thingiverse.com])

Somebody just got the new Marlin (Merlin?) firmware working on his Ultimaker and says: "So far, it's been working fine at prints 0.2 mm layer height; feedrate 300 mm/s; travel 900mm/s" so I guess I'm not really pushing my machine that hard.. [groups.google.com] .

> Skeinforge gives me an expected print time; does anyone know how accurate this is to real life? I must say I have never actually checked myself.

It's accurate as far as adding up the various move commands at different speeds. Sprinter may (will) slow things down at various points to handle acceleration, which will make the print take longer than skeinforge estimated. How much longer depends on how often the firmware slows things down on you.

> How can I externally check if it’s actually running at the speed I have set in Skeinforge?

I don't think you can, unless you want to modify the firmware to report on things like that.

Not sure about the rest of your questions..

Edited 1 time(s). Last edit at 08/23/2011 09:51AM by Dave Durant.

|

Re: Constant high-speed printing August 23, 2011 10:42AM |

Admin Registered: 17 years ago Posts: 7,879 |

Are these numbers real or is the acceleration limiting the max speed to nowhere near that? I find them hard to believe.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Constant high-speed printing August 23, 2011 11:23AM |

Registered: 12 years ago Posts: 90 |

> Are these numbers real or is the acceleration limiting the max speed to nowhere near that?

Good question..

On mine, I literally can't follow travel moves less than a couple cm. It's like some quantum thing where the head is in one spot then it's suddenly in another spot. It really is that fast and, TBH, pretty freaky to watch.

I'm sure acceleration is limiting the actual speed, especially on short moves and double-especially on that 900mm/s bit, but it may not be as far off as you think. I don't really have a decent way to measure it, though.

Good question..

On mine, I literally can't follow travel moves less than a couple cm. It's like some quantum thing where the head is in one spot then it's suddenly in another spot. It really is that fast and, TBH, pretty freaky to watch.

I'm sure acceleration is limiting the actual speed, especially on short moves and double-especially on that 900mm/s bit, but it may not be as far off as you think. I don't really have a decent way to measure it, though.

|

Re: Constant high-speed printing August 23, 2011 03:17PM |

Admin Registered: 16 years ago Posts: 13,891 |

... draw a hollow square with let's say 10cm in XY some layers high and measure the time from start to end, so you'll get a feeling for the possible speeds...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Constant high-speed printing August 23, 2011 04:41PM |

Registered: 13 years ago Posts: 1,797 |

|

Re: Constant high-speed printing August 23, 2011 05:03PM |

Registered: 13 years ago Posts: 818 |

Thanks for the info, I am going to have to try many more things to work out ideal speeds for sprinter then.

At least my latest hot-end seems to go as fast as I like with very little temperature drop so now I expect the hobbed bolt drive will start to fail at much faster speeds.

Maybe printing a 150mm Solid cube will start to tell me what the real firmware limits are. If I time it to build it say 5mm high at one speed then keep on stepping up the speed I should be able to measure when acceleration limit or the firmware processing speed limit cuts in.

I'll try it as soon as I get a chance.

Thanks,

Rich

[richrap.blogspot.com]

At least my latest hot-end seems to go as fast as I like with very little temperature drop so now I expect the hobbed bolt drive will start to fail at much faster speeds.

Maybe printing a 150mm Solid cube will start to tell me what the real firmware limits are. If I time it to build it say 5mm high at one speed then keep on stepping up the speed I should be able to measure when acceleration limit or the firmware processing speed limit cuts in.

I'll try it as soon as I get a chance.

Thanks,

Rich

[richrap.blogspot.com]

|

Re: Constant high-speed printing August 23, 2011 05:05PM |

Admin Registered: 17 years ago Posts: 7,879 |

I don't know what pulleys Ulitmaker use but 1000mm/s is 25 RPS with the pulleys we use. That is 10000 half steps per second! Most stepper motor data sheets show the torque going to next to nothing at that speed and it is usually shown with a 24V driver. If microstepping is used then I doubt the Arduino can step anywhere near that speed.

When slow acceleration is use quoting just the max speed is meaningless. It may never be reached in a full diagonal traversal of the bed and if not the average speed is only half the actual peak speed reached.

[www.hydraraptor.blogspot.com]

When slow acceleration is use quoting just the max speed is meaningless. It may never be reached in a full diagonal traversal of the bed and if not the average speed is only half the actual peak speed reached.

[www.hydraraptor.blogspot.com]

|

Re: Constant high-speed printing August 23, 2011 05:12PM |

Registered: 13 years ago Posts: 485 |

jamesdanielv Wrote:

-------------------------------------------------------

> acceleration rate almost never has enough time in

> a path to reach top speed.

You can hear when it is at constant speed, or accelerating. I had to make a special long test part when I was doing speed tests a couple months ago. I had just installed Sprinter, and I wanted to know what the real speed limit was.

The limiting factor for speed is not how fast the stepper motors can turn, but how fast the nozzle can extrude plastic. Using a MakerGear metric Prusa, 0.35 nozzle and 1.75mm black ABS, with RAMPS 1.2 on Arduino 2560, I tested as fast as 1200mm/sec. During the high speed portions of a move, the extrudate was very thin, mostly breaking into little balls on the print bed. During the slow portions of the move, the part would be overstuffed, as the pressurized plastic gushed out of the extruder. I had been elevating temperatures to get higher and higher speed. I tried as high as 250°C and never got better flow at 1200mm/sec. (I normally extrude that plastic at 210°C indicated.) I might have gone faster with a larger nozzle, but then I'd probably need a more powerful hot end heater to go with it.

IIRC, I'm using 1/16 microstepping on X and Y. Maybe 1/8. It's been a long time since I was under the stepper drivers. Pulleys are 8-tooth T5.

I think it was actually going that fast. I was incrementally increasing speed until the extrusion failed for some reason, then turned up the heat until it worked again, then the next faster speed step, etc. The increasing temperature requirements tell me that the speed was actually increasing.

I wonder if a hobbed-bolt extruder can go that fast. MakerGear's geared extruder really bites into the 1.75 filament.

For a while after the speed testing, I set Skeinforge to run at 300 mm/s, but the variability of extrudate width, even at that slow speed (felt like it, after testing at 1200), resulted in very poor prints. Lately I've been running at 100, with perimeters at 30. I also decreased the rate of acceleration after a print set up a resonance in the printer, resulting in lost steps.

I'm thinking about the accuracy doubling mod as a way to double acceleration. I already have more position accuracy than I can use, and much more speed.

Looks like I posted a video.

Edited 3 time(s). Last edit at 08/23/2011 05:21PM by Dale Dunn.

-------------------------------------------------------

> acceleration rate almost never has enough time in

> a path to reach top speed.

You can hear when it is at constant speed, or accelerating. I had to make a special long test part when I was doing speed tests a couple months ago. I had just installed Sprinter, and I wanted to know what the real speed limit was.

The limiting factor for speed is not how fast the stepper motors can turn, but how fast the nozzle can extrude plastic. Using a MakerGear metric Prusa, 0.35 nozzle and 1.75mm black ABS, with RAMPS 1.2 on Arduino 2560, I tested as fast as 1200mm/sec. During the high speed portions of a move, the extrudate was very thin, mostly breaking into little balls on the print bed. During the slow portions of the move, the part would be overstuffed, as the pressurized plastic gushed out of the extruder. I had been elevating temperatures to get higher and higher speed. I tried as high as 250°C and never got better flow at 1200mm/sec. (I normally extrude that plastic at 210°C indicated.) I might have gone faster with a larger nozzle, but then I'd probably need a more powerful hot end heater to go with it.

IIRC, I'm using 1/16 microstepping on X and Y. Maybe 1/8. It's been a long time since I was under the stepper drivers. Pulleys are 8-tooth T5.

I think it was actually going that fast. I was incrementally increasing speed until the extrusion failed for some reason, then turned up the heat until it worked again, then the next faster speed step, etc. The increasing temperature requirements tell me that the speed was actually increasing.

I wonder if a hobbed-bolt extruder can go that fast. MakerGear's geared extruder really bites into the 1.75 filament.

For a while after the speed testing, I set Skeinforge to run at 300 mm/s, but the variability of extrudate width, even at that slow speed (felt like it, after testing at 1200), resulted in very poor prints. Lately I've been running at 100, with perimeters at 30. I also decreased the rate of acceleration after a print set up a resonance in the printer, resulting in lost steps.

I'm thinking about the accuracy doubling mod as a way to double acceleration. I already have more position accuracy than I can use, and much more speed.

Looks like I posted a video.

Edited 3 time(s). Last edit at 08/23/2011 05:21PM by Dale Dunn.

|

Re: Constant high-speed printing August 23, 2011 06:39PM |

Registered: 13 years ago Posts: 177 |

I found it becomes much more difficult to get nice results from the extruder as you try to make it work faster.

60mm/s is the max reliable speed I can do. That's the actual speed reached. Faster than the and it starts to become increasingly difficult to keep quality.

When I discussed this in a thread I started that it seems to need a lot more pressure to extrude double as fast. Someone did explain the maths but if I remember I don't think it is linear. If you try pushing the filament through by hand you get a good feel of this. This means it has to take more time to increase the pressure when starting and need lots more grip to push the filament just to double the speed. The whole thing starts to become harder and harder to make start and stop nicely.

I think the pressures just become too high to be practical. There may be ways round this and other designs of extruder may handle this much better than mine but it still seems the limiting factor to me.

Please post some video of your machines running fast and the layer heights you are printing at. You can travel fast with a thin layer height and not be needing to extrude any faster than before. But the build time for a given volume will be the same as it was with a thicker layer moving slower. You may have a nicer finish however.

Make your Mendel twice as accurate.

[www.thingiverse.com]

60mm/s is the max reliable speed I can do. That's the actual speed reached. Faster than the and it starts to become increasingly difficult to keep quality.

When I discussed this in a thread I started that it seems to need a lot more pressure to extrude double as fast. Someone did explain the maths but if I remember I don't think it is linear. If you try pushing the filament through by hand you get a good feel of this. This means it has to take more time to increase the pressure when starting and need lots more grip to push the filament just to double the speed. The whole thing starts to become harder and harder to make start and stop nicely.

I think the pressures just become too high to be practical. There may be ways round this and other designs of extruder may handle this much better than mine but it still seems the limiting factor to me.

Please post some video of your machines running fast and the layer heights you are printing at. You can travel fast with a thin layer height and not be needing to extrude any faster than before. But the build time for a given volume will be the same as it was with a thicker layer moving slower. You may have a nicer finish however.

Make your Mendel twice as accurate.

[www.thingiverse.com]

|

Re: Constant high-speed printing August 23, 2011 08:42PM |

Registered: 13 years ago Posts: 581 |

|

Re: Constant high-speed printing August 23, 2011 09:27PM |

Registered: 12 years ago Posts: 90 |

Tough crowd..

nophead Wrote:

-------------------------------------------------------

> I don't know what pulleys Ulitmaker use but

> 1000mm/s is 25 RPS with the pulleys we use. That

> is 10000 half steps per second! Most stepper motor

> data sheets show the torque going to next to

> nothing at that speed and it is usually shown with

> a 24V driver. If microstepping is used then I

> doubt the Arduino can step anywhere near that

> speed.

Like I said earlier in this thread: "I'm sure acceleration is limiting the actual speed, especially on short moves and double-especially on that 900mm/s bit, but it may not be as far off as you think. I don't really have a decent way to measure it, though."

If you haven't seen one recently, you should run across that river/channel thing and get Erik to give you a demo! You WILL be surprised at how fast these things can move. Puny moving mass and all that..

VDX wrote:

-------------------------------------------------------

.> .. draw a hollow square with let's say 10cm in XY some layers high and measure the time from start to end, so you'll get a feeling for the possible speeds...

Oh. Duh. Good idea.. I'm (hopefully) closing in on getting a controller going so I can run headless - that should allow me to get some pretty accurate numbers, though impatient people who grok acceleration code can probably just look at the source and figure it out, if they wanted to.

Andrew Diehl wrote:

-------------------------------------------------------

> From my very limited experience, there is a lot of "I can print super fast" and very little "with good quality."

>

> For any speed claims to be meaningful there needs to be a detailed photo showing what the actual print looks like.

Yes, printing at higher speeds can definitely reduce quality. Any time you push the current limits, you just find more limits underneath. Turtles all the way down.

Aside from the picture I posted earlier in this thread, the thingiverse link, I don't have many of stuff I've printed at high speed. And, again, that's only at 150mm/s non-travel with 50mm/s on the perimeter.

Somebody did post a short video of the same print at [www.youtube.com] . Not sure what's up with the slowdowns near the start - mine didn't have anything like that and I suspect it's a youtube illusion. You can also see the quality better than in my picture, and it's not bad. Sadly, the video doesn't seem to show many (any?) travel moves, which were a LOT faster than the printing moves. Dunno if they were actually 3x the rate, though.

Anyway, I think the video sorta answers some of the OPs questions.. Sprinter with a Mega can go pretty darned quickly, even with tons & tons of tiny moves. You'll probably run out of hardware before you run out of electronics, even at 16x microstepping.

nophead Wrote:

-------------------------------------------------------

> I don't know what pulleys Ulitmaker use but

> 1000mm/s is 25 RPS with the pulleys we use. That

> is 10000 half steps per second! Most stepper motor

> data sheets show the torque going to next to

> nothing at that speed and it is usually shown with

> a 24V driver. If microstepping is used then I

> doubt the Arduino can step anywhere near that

> speed.

Like I said earlier in this thread: "I'm sure acceleration is limiting the actual speed, especially on short moves and double-especially on that 900mm/s bit, but it may not be as far off as you think. I don't really have a decent way to measure it, though."

If you haven't seen one recently, you should run across that river/channel thing and get Erik to give you a demo! You WILL be surprised at how fast these things can move. Puny moving mass and all that..

VDX wrote:

-------------------------------------------------------

.> .. draw a hollow square with let's say 10cm in XY some layers high and measure the time from start to end, so you'll get a feeling for the possible speeds...

Oh. Duh. Good idea.. I'm (hopefully) closing in on getting a controller going so I can run headless - that should allow me to get some pretty accurate numbers, though impatient people who grok acceleration code can probably just look at the source and figure it out, if they wanted to.

Andrew Diehl wrote:

-------------------------------------------------------

> From my very limited experience, there is a lot of "I can print super fast" and very little "with good quality."

>

> For any speed claims to be meaningful there needs to be a detailed photo showing what the actual print looks like.

Yes, printing at higher speeds can definitely reduce quality. Any time you push the current limits, you just find more limits underneath. Turtles all the way down.

Aside from the picture I posted earlier in this thread, the thingiverse link, I don't have many of stuff I've printed at high speed. And, again, that's only at 150mm/s non-travel with 50mm/s on the perimeter.

Somebody did post a short video of the same print at [www.youtube.com] . Not sure what's up with the slowdowns near the start - mine didn't have anything like that and I suspect it's a youtube illusion. You can also see the quality better than in my picture, and it's not bad. Sadly, the video doesn't seem to show many (any?) travel moves, which were a LOT faster than the printing moves. Dunno if they were actually 3x the rate, though.

Anyway, I think the video sorta answers some of the OPs questions.. Sprinter with a Mega can go pretty darned quickly, even with tons & tons of tiny moves. You'll probably run out of hardware before you run out of electronics, even at 16x microstepping.

|

Re: Constant high-speed printing August 24, 2011 11:38AM |

Registered: 16 years ago Posts: 293 |

I should also measure still measure the speeds, but Martijn and I have been able to do a few prints about three times faster with the same level of quality. The attached prints look almost identical, but the one on the right was printed at 3 times the speed. Layer height is about 0.08... I'm not entirely sure. Sorry to be vague, I'm typing this in a hurry.

Note there are many video's about Marlin and Ultimaker already:

[www.youtube.com]

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

Note there are many video's about Marlin and Ultimaker already:

[www.youtube.com]

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

|

Re: Constant high-speed printing August 24, 2011 12:59PM |

Registered: 13 years ago Posts: 632 |

I keep wondering the same thing as Madkite, is the overall build time that different, or is it just pushing a smaller layer height or width at higher speeds? Other than thin walled hollow objects, is there that much advantage in total print time? I'm thinking "time to print a Prusa set" type tests. Anyone printing sets of prusa parts in 8 h these days?

|

Re: Constant high-speed printing August 24, 2011 01:39PM |

Registered: 12 years ago Posts: 90 |

> I keep wondering the same thing as Madkite, is the overall build time that different, or is

> it just pushing a smaller layer height or width at higher speeds?

In general, if you can reliably and accurately increase the rate which you can push plastic through the machine, you can decrease your print time. Doing that doesn't necessarily require (or prevent) a change in thread dimensions.

> Other than thin walled hollow objects, is there that much advantage in total print time?

Sure. If you can push plastic at a higher rate without losing quality, print time will go down. Who doesn't want prints to happen faster?

How much you can cut the print time depends on what you're comparing against. I've got a cupcake and an ultimaker - my ultimaker can easily turn out an object 5x as fast as my cupcake can, at the same thread dimensions and resulting quality. Different types of machines will, of course, compare differently.

> it just pushing a smaller layer height or width at higher speeds?

In general, if you can reliably and accurately increase the rate which you can push plastic through the machine, you can decrease your print time. Doing that doesn't necessarily require (or prevent) a change in thread dimensions.

> Other than thin walled hollow objects, is there that much advantage in total print time?

Sure. If you can push plastic at a higher rate without losing quality, print time will go down. Who doesn't want prints to happen faster?

How much you can cut the print time depends on what you're comparing against. I've got a cupcake and an ultimaker - my ultimaker can easily turn out an object 5x as fast as my cupcake can, at the same thread dimensions and resulting quality. Different types of machines will, of course, compare differently.

|

Re: Constant high-speed printing August 24, 2011 04:50PM |

Registered: 12 years ago Posts: 313 |

nophead Wrote:

-------------------------------------------------------

> Are these numbers real or is the acceleration

> limiting the max speed to nowhere near that? I

> find them hard to believe.

I have no idea about the ridiculous 1000+mm/s numbers, but I did some test prints at 150mm/s and here's a video: 150mm/s with Orca and Marlin

I checked the timing from the video and when the three perimeter tracks for the second layer are printed at full speed, it takes 3.8 seconds. That's 3*4*40mm to travel and equals 126mm/s average speed. I think that's pretty good, considering how many stops there are on the way.

Some other notes:

I noticed too that the extruder is the limiting factor. So once you hit the limit of how much plastic you can push through it in a second, the only thing the increased print head feed rate gets you is the ability to make the object from thinner extrudate in the same time. If the machine and firmware are up to it...

The melting point for most materials increases under pressure. When extruding faster, the pressure in the hotend is higher and a higher temperature should be used just to keep the viscosity the same. Maybe? Anyone got data about PLA or ABS?

-------------------------------------------------------

> Are these numbers real or is the acceleration

> limiting the max speed to nowhere near that? I

> find them hard to believe.

I have no idea about the ridiculous 1000+mm/s numbers, but I did some test prints at 150mm/s and here's a video: 150mm/s with Orca and Marlin

I checked the timing from the video and when the three perimeter tracks for the second layer are printed at full speed, it takes 3.8 seconds. That's 3*4*40mm to travel and equals 126mm/s average speed. I think that's pretty good, considering how many stops there are on the way.

Some other notes:

I noticed too that the extruder is the limiting factor. So once you hit the limit of how much plastic you can push through it in a second, the only thing the increased print head feed rate gets you is the ability to make the object from thinner extrudate in the same time. If the machine and firmware are up to it...

The melting point for most materials increases under pressure. When extruding faster, the pressure in the hotend is higher and a higher temperature should be used just to keep the viscosity the same. Maybe? Anyone got data about PLA or ABS?

|

Re: Constant high-speed printing August 24, 2011 06:41PM |

Admin Registered: 17 years ago Posts: 7,879 |

150mm/s is reasonable. I got to 100mm/s with PLA on my Mendel before I added the heavy heated bed and the big heatsink on my extruder.

I think that the flow rate through the nozzle is directly proportional to pressure, so there is a finite limit to the flow rate you can get from the grip afforded by the pinch wheel.

However, as speed increases the time taken for the plastic to melt may become the limiting factor. Plastic is a poor conductor, and has a high specific heat capacity, so it takes time for the heat to get to the middle of the filament and melt it. As you get faster you will hit a point where the plastic has not got up to temperature before it gets to the nozzle, so its viscosity on exit will increase, causing the force to rise much more steeply. To overcome that you will need a bigger melt chamber and a more powerful heater.

Edited 1 time(s). Last edit at 08/24/2011 06:44PM by nophead.

[www.hydraraptor.blogspot.com]

I think that the flow rate through the nozzle is directly proportional to pressure, so there is a finite limit to the flow rate you can get from the grip afforded by the pinch wheel.

However, as speed increases the time taken for the plastic to melt may become the limiting factor. Plastic is a poor conductor, and has a high specific heat capacity, so it takes time for the heat to get to the middle of the filament and melt it. As you get faster you will hit a point where the plastic has not got up to temperature before it gets to the nozzle, so its viscosity on exit will increase, causing the force to rise much more steeply. To overcome that you will need a bigger melt chamber and a more powerful heater.

Edited 1 time(s). Last edit at 08/24/2011 06:44PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Constant high-speed printing August 24, 2011 08:58PM |

Registered: 12 years ago Posts: 90 |

I just tried a quick test, which, in retrospect, was poorly thought out and not very interesting.. Three good ol' 20mm cubes at .25mm layer height, 1.5 w/t, .15 rectangular fill.

A whole five seconds of thought would have told me that the max thread length would be under 30mm and that would only be a few lines on the solid layers, which isn't long at all and probably not the best test when talking about acceleration. Most lines, the fill, are probably 5-10mm..

Anyway, the numbers I scribbled down were:

First column was the infill/perimeter/travel feed rate - no games with slowing the perimeter to make it look decent, though 1st-layer was set to 40% feed/55% flow. Second column is how long each print took. Third column is the estimated time and average feed rate that skeinforge predicted.

The times include homing, test extrusion, clean the test extrusion M1, skirt and slower first layer so that throws things off.. I sorta fumbled the 200mm/s one at the start - maybe 10 extra seconds there.

Clearly, acceleration is playing a big factor in this and slowing things down.

Also clearly, telling it to go faster does indeed make it go faster - acceleration may be slowing it down but it's still hitting (or closing in on anyway) max speed for some non-trivial number of threads. With a bigger print (and a 1/2 decent test methodology), the time differences would be bigger.

I tried, a number of times, to get a decent picture of the results but my camera hates transparent PLA, which is all I've got right now. In person, they look pretty similar to each other except that the faster ones suffer more from heat problems - layers were only taking a few seconds to complete..

Edited 1 time(s). Last edit at 08/24/2011 11:25PM by Dave Durant.

A whole five seconds of thought would have told me that the max thread length would be under 30mm and that would only be a few lines on the solid layers, which isn't long at all and probably not the best test when talking about acceleration. Most lines, the fill, are probably 5-10mm..

Anyway, the numbers I scribbled down were:

100mm/s 4:34 3:28 @ 89.2mm/s 200mm/s 4:06 1:46 @ 175.9mm/s 300mm/s 3:00 1:11 @ 260.2mm/s

First column was the infill/perimeter/travel feed rate - no games with slowing the perimeter to make it look decent, though 1st-layer was set to 40% feed/55% flow. Second column is how long each print took. Third column is the estimated time and average feed rate that skeinforge predicted.

The times include homing, test extrusion, clean the test extrusion M1, skirt and slower first layer so that throws things off.. I sorta fumbled the 200mm/s one at the start - maybe 10 extra seconds there.

Clearly, acceleration is playing a big factor in this and slowing things down.

Also clearly, telling it to go faster does indeed make it go faster - acceleration may be slowing it down but it's still hitting (or closing in on anyway) max speed for some non-trivial number of threads. With a bigger print (and a 1/2 decent test methodology), the time differences would be bigger.

I tried, a number of times, to get a decent picture of the results but my camera hates transparent PLA, which is all I've got right now. In person, they look pretty similar to each other except that the faster ones suffer more from heat problems - layers were only taking a few seconds to complete..

Edited 1 time(s). Last edit at 08/24/2011 11:25PM by Dave Durant.

|

Re: Constant high-speed printing August 24, 2011 11:12PM |

Registered: 13 years ago Posts: 632 |

OK, that makes sense. That might be a worst case scenario. I guess you could expect to maybe cut the time in half to a third on larger objects. I'd still be interested in a total print time from any prusa printers out there. How about it, anyone print a prusa in 8 h? anyone break the 3 Ppd mark? (Prusa's per day, it's like furlongs per fortnight)

|

Re: Constant high-speed printing August 24, 2011 11:49PM |

Registered: 12 years ago Posts: 90 |

bryanandaimee Wrote:

-------------------------------------------------------

> OK, that makes sense. That might be a worst case

> scenario. I guess you could expect to maybe cut

> the time in half to a third on larger objects. I'd

> still be interested in a total print time from any

> prusa printers out there. How about it, anyone

> print a prusa in 8 h? anyone break the 3 Ppd mark?

> (Prusa's per day, it's like furlongs per

> fortnight)

I'm not sure it's really worst-case any more (edit: even though I still think my test was poorly executed). I've never printed a Prusa but it seems like a whole bunch of fairly small pieces, which may well run into the same sorta problem - I guess a lot depends on how skeinforge lays things out.

Even on bigger objects, if you don't print 100% solid and use rectangular fill, most of the print will be composed on fairly small lines. The new marlin firmware is (supposedly) a lot better a maintaining head speed whenever possible so that might work well, speed wise, with the hex fill. Or you could use line fill, which would be fastest but I don't think that's as strong as rectangular/hex..

As for having prints take 1/2 or 1/3rd the time, that'll be tough unless you've really been taking it easy on your machine.. There are almost always ways to get improvements but chopping off 1/2 the time would be quite a trick..

Edited 1 time(s). Last edit at 08/24/2011 11:50PM by Dave Durant.

-------------------------------------------------------

> OK, that makes sense. That might be a worst case

> scenario. I guess you could expect to maybe cut

> the time in half to a third on larger objects. I'd

> still be interested in a total print time from any

> prusa printers out there. How about it, anyone

> print a prusa in 8 h? anyone break the 3 Ppd mark?

> (Prusa's per day, it's like furlongs per

> fortnight)

I'm not sure it's really worst-case any more (edit: even though I still think my test was poorly executed). I've never printed a Prusa but it seems like a whole bunch of fairly small pieces, which may well run into the same sorta problem - I guess a lot depends on how skeinforge lays things out.

Even on bigger objects, if you don't print 100% solid and use rectangular fill, most of the print will be composed on fairly small lines. The new marlin firmware is (supposedly) a lot better a maintaining head speed whenever possible so that might work well, speed wise, with the hex fill. Or you could use line fill, which would be fastest but I don't think that's as strong as rectangular/hex..

As for having prints take 1/2 or 1/3rd the time, that'll be tough unless you've really been taking it easy on your machine.. There are almost always ways to get improvements but chopping off 1/2 the time would be quite a trick..

Edited 1 time(s). Last edit at 08/24/2011 11:50PM by Dave Durant.

|

Re: Constant high-speed printing August 25, 2011 04:39AM |

Registered: 13 years ago Posts: 818 |

nophead Wrote:

-------------------------------------------------------

>

> However, as speed increases the time taken for the

> plastic to melt may become the limiting factor.

> Plastic is a poor conductor, and has a high

> specific heat capacity, so it takes time for the

> heat to get to the middle of the filament and melt

> it. As you get faster you will hit a point where

> the plastic has not got up to temperature before

> it gets to the nozzle, so its viscosity on exit

> will increase, causing the force to rise much more

> steeply. To overcome that you will need a bigger

> melt chamber and a more powerful heater.

I have a slightly more powerful heater block and also a longer heating zone in my new extruder, and I am starting to see the hobbed bolt drive start to fail at speeds over 190mm/sec with 3mm PLA and 100% infill, so this is still indicating insufficient time for heating or too high pressure for the hobbed bolt to drive the filament as nophead states.

It looks like I can get it to go faster running the PLA at 245 degrees C, but I'm really not sure that's a good idea as the PLA is going to start breaking down.

I can't get to this speed with 3mm ABS, just a grinding of the filament, my hobbed bolt has very fine teeth. Is anyone using a much more course hobbed bolt or any other filament drive that can push without grinding filament?

Just a thought - How about a very large hobbed filament drive wheel, say 60mm (I'm thinking hobbing a brass Meccano pulley), curve the filament around 1/4 of it and put pressure on the filament say at 3 points with 3 small bearings and drive it with a decent geared stepper. - Anyone tried this? thoughts?

[richrap.blogspot.com]

-------------------------------------------------------

>

> However, as speed increases the time taken for the

> plastic to melt may become the limiting factor.

> Plastic is a poor conductor, and has a high

> specific heat capacity, so it takes time for the

> heat to get to the middle of the filament and melt

> it. As you get faster you will hit a point where

> the plastic has not got up to temperature before

> it gets to the nozzle, so its viscosity on exit

> will increase, causing the force to rise much more

> steeply. To overcome that you will need a bigger

> melt chamber and a more powerful heater.

I have a slightly more powerful heater block and also a longer heating zone in my new extruder, and I am starting to see the hobbed bolt drive start to fail at speeds over 190mm/sec with 3mm PLA and 100% infill, so this is still indicating insufficient time for heating or too high pressure for the hobbed bolt to drive the filament as nophead states.

It looks like I can get it to go faster running the PLA at 245 degrees C, but I'm really not sure that's a good idea as the PLA is going to start breaking down.

I can't get to this speed with 3mm ABS, just a grinding of the filament, my hobbed bolt has very fine teeth. Is anyone using a much more course hobbed bolt or any other filament drive that can push without grinding filament?

Just a thought - How about a very large hobbed filament drive wheel, say 60mm (I'm thinking hobbing a brass Meccano pulley), curve the filament around 1/4 of it and put pressure on the filament say at 3 points with 3 small bearings and drive it with a decent geared stepper. - Anyone tried this? thoughts?

[richrap.blogspot.com]

|

Re: Constant high-speed printing August 25, 2011 06:05AM |

Admin Registered: 17 years ago Posts: 7,879 |

I think all the examples of very high speeds use PLA because it is much less viscous, harder - so gets more grip and stiffer so less likely to buckle. Going fast with ABS is going to be much more difficult.

A longer contact area from a bigger diameter will certainly give more grip but the torque at the axle would be very high. You could fasten the pulley to a large gear face to face and drive that with a small one to get back to the sort of torque and gear ratio we normally use.

[www.hydraraptor.blogspot.com]

A longer contact area from a bigger diameter will certainly give more grip but the torque at the axle would be very high. You could fasten the pulley to a large gear face to face and drive that with a small one to get back to the sort of torque and gear ratio we normally use.

[www.hydraraptor.blogspot.com]

|

Re: Constant high-speed printing August 25, 2011 06:57AM |

Registered: 13 years ago Posts: 818 |

|

Re: Constant high-speed printing August 26, 2011 02:09AM |

Registered: 13 years ago Posts: 485 |

...

> I can't get to this speed with 3mm ABS, just a

> grinding of the filament, my hobbed bolt has very

> fine teeth. Is anyone using a much more course

> hobbed bolt or any other filament drive that can

> push without grinding filament?

...

Yes. The MakerGear extruder uses a gear instead of a hobbed bolt. The teeth bite about 0.5mm into the 1.75mm filament I'm using. The filament buckles in the extruder about as often as it strips. All my experience is with ABS, so I'm not sure what PLA does in there. Much deeper than that and 1.75mm filament buckles too easily.

The 1.75mm filament should theoretically require less force to generate the same pressure in the melt chamber. I don't think the MG hot end gets all of that advantage though, since it's the same for either filament size. It may get some of the advantage, as the solid filament probably pushes through the melt plug more than constantly making a new melt plug. (Maybe this is why some color changes take so much longer than others.) 3mm filament's greater resistance to buckling might allow higher melt chamber pressure, even though it should be pushing the whole melt plug.

The MakerGear drive gear is S10T05M020S0508 here (.pdf). You could probably mount it on the body of an M8 screw if you file a flat on one side. You might get a better fit on an 8mm shoulder screw, though. You wouldn't want a sloppy fit, or the gear will be eccentric and give you inconsistent flow. The extruder frame would have to be tweaked for the larger diameter, of course.

> I can't get to this speed with 3mm ABS, just a

> grinding of the filament, my hobbed bolt has very

> fine teeth. Is anyone using a much more course

> hobbed bolt or any other filament drive that can

> push without grinding filament?

...

Yes. The MakerGear extruder uses a gear instead of a hobbed bolt. The teeth bite about 0.5mm into the 1.75mm filament I'm using. The filament buckles in the extruder about as often as it strips. All my experience is with ABS, so I'm not sure what PLA does in there. Much deeper than that and 1.75mm filament buckles too easily.

The 1.75mm filament should theoretically require less force to generate the same pressure in the melt chamber. I don't think the MG hot end gets all of that advantage though, since it's the same for either filament size. It may get some of the advantage, as the solid filament probably pushes through the melt plug more than constantly making a new melt plug. (Maybe this is why some color changes take so much longer than others.) 3mm filament's greater resistance to buckling might allow higher melt chamber pressure, even though it should be pushing the whole melt plug.

The MakerGear drive gear is S10T05M020S0508 here (.pdf). You could probably mount it on the body of an M8 screw if you file a flat on one side. You might get a better fit on an 8mm shoulder screw, though. You wouldn't want a sloppy fit, or the gear will be eccentric and give you inconsistent flow. The extruder frame would have to be tweaked for the larger diameter, of course.

|

Re: Constant high-speed printing August 26, 2011 03:10AM |

Admin Registered: 17 years ago Posts: 7,879 |

For 1.75mm filament you need all the filament path smaller to get the advantage. Otherwise you form a bigger melt plug (due to more backflow) but are pushing it with a much weaker filament. I discovered this when I tried to use 2mm PMMA in my extruder designed for 3mm filament.

Edited 1 time(s). Last edit at 08/26/2011 03:12AM by nophead.

[www.hydraraptor.blogspot.com]

Edited 1 time(s). Last edit at 08/26/2011 03:12AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Constant high-speed printing August 26, 2011 04:09AM |

I think the best extruder would be 2 hobbed bolts/gears on both sides of the filament driving the filament forward, and as efficient as possible heating resistor on the end.

The speed goes down because the temperature goes down, hothead should have enough power to maintain the temperature, and there should be enough friction to push the filament, therefore 2 hobbed bolts getting force from one stepper motor through gears...

The speed goes down because the temperature goes down, hothead should have enough power to maintain the temperature, and there should be enough friction to push the filament, therefore 2 hobbed bolts getting force from one stepper motor through gears...

|

Re: Constant high-speed printing August 26, 2011 04:59AM |

Admin Registered: 17 years ago Posts: 7,879 |

It's tricky to do with gears because one pulley is floating. A single, larger pulley might give the same grip due to longer contact area.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Constant high-speed printing August 26, 2011 05:45AM |

Registered: 13 years ago Posts: 818 |

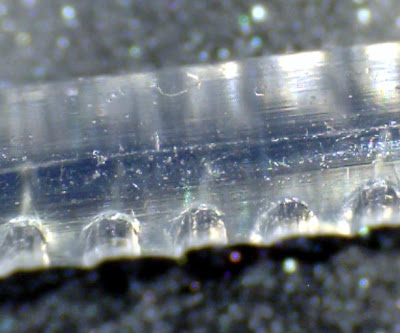

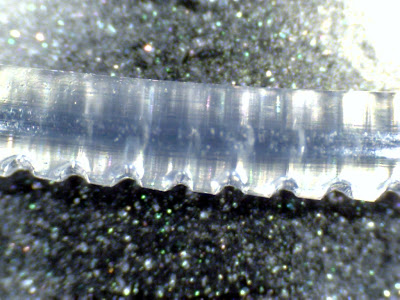

I read back Nopheads blog post on Knurled v Hobbing and it may actually be worth using Knurling rather than hobbing when you use a bigger drive wheel, the contact area will be much greater and as long as you can apply idler pressure across a section or a few points the knurling may cause less damage to the filament, and be less likely to strip or gouge the filament.

Many of the hobbed bolts just seem to dig into the edges of the filament and the small teeth on the sides do most of the transport, if you have too much idler pressure or resistance from the hot-end it just starts cutting the filament, slipping and making a mess.

I'm getting less convinced hobbed bolts are a good idea, certainly my experience is now that this is the main problem area I need to resolve.

My most reliable and best filament drive system to-date is still the old style Brass fitting Adrian used to use before also moving to a hobbed bolt, I have never had any jamming or filament stripping using this style.

It had dull teeth, not sharp and you can apply high pressure to the idler without stripping the filament, you just need to make sure the filament is constrained otherwise it just slips off the side of the drive. I'm thinking that a much larger version of this drive wheel would be really good.

This is 1.75mm filament, it grips well and is uniform -

When I get a chance I will take a look at what filament driven with a hobbed bolt looks like under a microscope, unless anyone else has already done this?

Maybe it's also time to think about doing real-time torque measurement on the gear so we are aware in firmware when things are about to strip the filament or if the temperature is too low for the plastic/speed etc?

[richrap.blogspot.com]

Many of the hobbed bolts just seem to dig into the edges of the filament and the small teeth on the sides do most of the transport, if you have too much idler pressure or resistance from the hot-end it just starts cutting the filament, slipping and making a mess.

I'm getting less convinced hobbed bolts are a good idea, certainly my experience is now that this is the main problem area I need to resolve.

My most reliable and best filament drive system to-date is still the old style Brass fitting Adrian used to use before also moving to a hobbed bolt, I have never had any jamming or filament stripping using this style.

It had dull teeth, not sharp and you can apply high pressure to the idler without stripping the filament, you just need to make sure the filament is constrained otherwise it just slips off the side of the drive. I'm thinking that a much larger version of this drive wheel would be really good.

This is 1.75mm filament, it grips well and is uniform -

When I get a chance I will take a look at what filament driven with a hobbed bolt looks like under a microscope, unless anyone else has already done this?

Maybe it's also time to think about doing real-time torque measurement on the gear so we are aware in firmware when things are about to strip the filament or if the temperature is too low for the plastic/speed etc?

[richrap.blogspot.com]

|

Re: Constant high-speed printing August 26, 2011 07:29AM |

Admin Registered: 17 years ago Posts: 7,879 |

I have never tried one of those but it looks like it would be good for PLA but not ABS, they are like chalk and cheese. If your hobbed bolt is only gripping on the edges you are not pressing the filament in far enough.

There are a lot of variables when making a hobbed drive: outer diameter, tap size, tap depth, idler pressure, idler diameter, idler profile. To my knowledge nobody has done any work trying to optimise these. I suspect the 8mm bolt is too small, I did my experiments with a 13mm diameter wheel. With a small pulley, not only is the contact length shorter, but the difference in speed of the outer part of the teeth compared to the inner is greater so you get a tearing action.

Currently filament feed rate isn't an issue for me because my machines are heavy and slow and I use a 0.5mm nozzle. I will do some work on this in the near future though as I have all the equipment needed explore all these variables.

[www.hydraraptor.blogspot.com]

There are a lot of variables when making a hobbed drive: outer diameter, tap size, tap depth, idler pressure, idler diameter, idler profile. To my knowledge nobody has done any work trying to optimise these. I suspect the 8mm bolt is too small, I did my experiments with a 13mm diameter wheel. With a small pulley, not only is the contact length shorter, but the difference in speed of the outer part of the teeth compared to the inner is greater so you get a tearing action.

Currently filament feed rate isn't an issue for me because my machines are heavy and slow and I use a 0.5mm nozzle. I will do some work on this in the near future though as I have all the equipment needed explore all these variables.

[www.hydraraptor.blogspot.com]

|

Re: Constant high-speed printing August 26, 2011 11:34AM |

The hot end should also be copper, when driving filament through it, the aluminium cools down too well when fed , copper conducts heat better and stores more heat also.

Copper conducts almost twice as much heat as aluminium..

Al radiates heat better..

Copper part of hothead to be heated, and under that an aluminium part that is actually the injector nozzle...would give best solution...my opinion..

Copper conducts almost twice as much heat as aluminium..

Al radiates heat better..

Copper part of hothead to be heated, and under that an aluminium part that is actually the injector nozzle...would give best solution...my opinion..

Sorry, only registered users may post in this forum.