Beltless reprap?

Posted by NelsonRap

|

Beltless reprap? October 02, 2011 08:12PM |

Registered: 13 years ago Posts: 862 |

Has anyone made a reprap with No belts, I was thinking use a threaded rod instead of one of the smooth rods with capture nuts on the X carriage, direct mount the motor as in the Prusa Z axis. I was thinking with a bit of tweaking of the design that this could be done for both the X carriage and the Y axis instead of belts.

Surely this would increase the accuracy but has anyone tried this with direct mounted motors? Afterall I don't want to reinvent the wheel as such if some one has already done and found it doesn't work

__________________________________________________________________________

Experimenting in 3D in New Zealand

Surely this would increase the accuracy but has anyone tried this with direct mounted motors? Afterall I don't want to reinvent the wheel as such if some one has already done and found it doesn't work

__________________________________________________________________________

Experimenting in 3D in New Zealand

|

Re: Beltless reprap? October 02, 2011 08:25PM |

Registered: 13 years ago Posts: 581 |

Why would it increase the accuracy? Short of using expensive ball screws, you will only add backlash and reduce speed.

Belts are far more accurate than most people give them credit for. The problem is usually either in improper tension, or lies somewhere else in the system. (assuming small loads)

Belts are far more accurate than most people give them credit for. The problem is usually either in improper tension, or lies somewhere else in the system. (assuming small loads)

|

Re: Beltless reprap? October 02, 2011 08:30PM |

Registered: 13 years ago Posts: 862 |

|

Re: Beltless reprap? October 02, 2011 08:50PM |

Registered: 13 years ago Posts: 581 |

|

Re: Beltless reprap? October 02, 2011 09:09PM |

Registered: 13 years ago Posts: 862 |

Part of my thinking was that if it had an extruder that could be changed for a tool it might work as a reprap or a mill, and I was thinking something silmilar to the old Darwin shape but to move the extruder up and down as in a Prusa and not raise the bed

__________________________________________________________________________

Experimenting in 3D in New Zealand

__________________________________________________________________________

Experimenting in 3D in New Zealand

|

Re: Beltless reprap? October 02, 2011 09:13PM |

Registered: 13 years ago Posts: 2,947 |

|

Re: Beltless reprap? October 03, 2011 05:38AM |

Registered: 14 years ago Posts: 3,742 |

Yes it would increase the accuracy and decrease the speed.

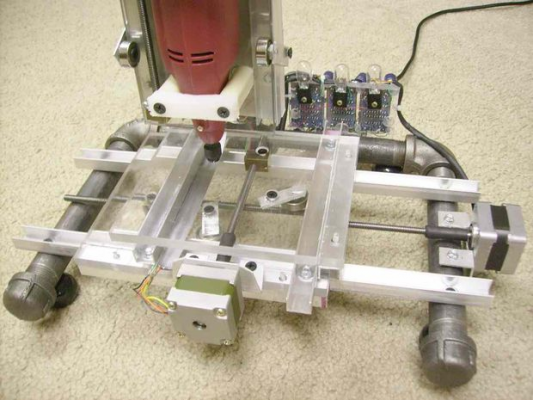

That is why the McWire is no longer recommended as a RepStrap.

It is easy to build and works fine but is VERY SLOW.

It is better as a CNC then as an FFF.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

That is why the McWire is no longer recommended as a RepStrap.

It is easy to build and works fine but is VERY SLOW.

It is better as a CNC then as an FFF.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Beltless reprap? October 03, 2011 05:40AM |

Registered: 15 years ago Posts: 376 |

You will need to use acme lead screws or similar and not standard threaded bar, otherwise the robot will be very slow (powerful but slow!)

Lead screw and nuts are not the easiest thing to source cheaply. (McMaster is only readily available in the US)

My delta robot design (Helium Frog Delta Robot) had this problem and in hindsight I would have been better using toothed belts. There is an additional problem in that if the lead screw isn't perfectly straight, you get the vibration transmitted to the tool head, this was very noticable on my delta robot.

Backlash could be a problem, but you can take this out with software as is this is already done in many industrial machine tools.

All in all unless you are going to use your robot for high load applications such as milling, you are probably best sticking with toothed belts.

I have had some similar thoughts about using a single lead screw to raise and lower the extruder on the x carriage on an old darwin type robot. I have looked into this and you can buy M10 threaded tube as its used regularly in the lighting industry. If you could keep the weight down (nema 11 motor perhaps of driving the z axis using a motor at the end of the x carriage or a bowden motor) this would have a lot of advantages, namely a reduced number of parts and also you could design a robot where the part doesn't move. This is great for using silicone heated beds or for powder boxes for laser sintering.

Lead screw and nuts are not the easiest thing to source cheaply. (McMaster is only readily available in the US)

My delta robot design (Helium Frog Delta Robot) had this problem and in hindsight I would have been better using toothed belts. There is an additional problem in that if the lead screw isn't perfectly straight, you get the vibration transmitted to the tool head, this was very noticable on my delta robot.

Backlash could be a problem, but you can take this out with software as is this is already done in many industrial machine tools.

All in all unless you are going to use your robot for high load applications such as milling, you are probably best sticking with toothed belts.

I have had some similar thoughts about using a single lead screw to raise and lower the extruder on the x carriage on an old darwin type robot. I have looked into this and you can buy M10 threaded tube as its used regularly in the lighting industry. If you could keep the weight down (nema 11 motor perhaps of driving the z axis using a motor at the end of the x carriage or a bowden motor) this would have a lot of advantages, namely a reduced number of parts and also you could design a robot where the part doesn't move. This is great for using silicone heated beds or for powder boxes for laser sintering.

|

Re: Beltless reprap? October 03, 2011 06:42AM |

Registered: 13 years ago Posts: 581 |

|

Re: Beltless reprap? October 03, 2011 07:40AM |

Admin Registered: 17 years ago Posts: 7,879 |

You get a pause when you change direction with backlash. That doesn't affect a mill but leads to a blob with FFF.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Beltless reprap? October 03, 2011 08:36AM |

Registered: 13 years ago Posts: 818 |

Don't use ballscrews, I made a machine with ballscrews, it works really well and has excellent accuracy but it's slow (very slow compared to a good Prusa with Linear bearings and 2.5mm belts)

If you want to improve quality use a finer nozzle on a Prusa and maybe if you still want to use ballscrews or ACME leadscrews then put them on the Z axis.

[richrap.blogspot.com]

If you want to improve quality use a finer nozzle on a Prusa and maybe if you still want to use ballscrews or ACME leadscrews then put them on the Z axis.

[richrap.blogspot.com]

|

Re: Beltless reprap? October 03, 2011 02:47PM |

Registered: 13 years ago Posts: 862 |

Sorry, only registered users may post in this forum.