Our Mendel90 Build Experience and Mods

Posted by SanjayM

|

Our Mendel90 Build Experience and Mods July 17, 2012 08:08PM |

Registered: 12 years ago Posts: 177 |

For the past few months me and a friend have been severely bitten by the RepRap bug, 5 months later,and after having built 4 different printers (1 kit, 3 self-sourced) and having done quite a lot of research and testing we thought we'd share on the forums with a bit of a review of the build process for a Mendel90 and hopefully incite some discussion about the design in general.

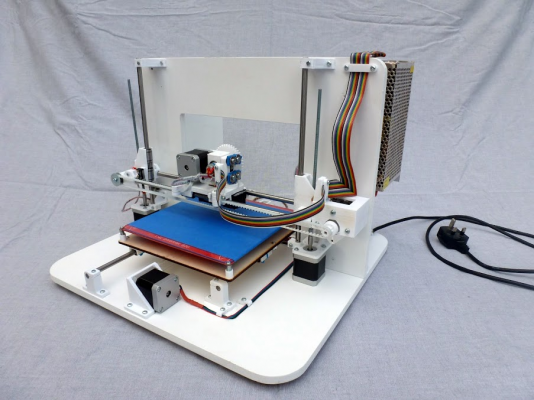

Firstly, a big thank-you to Nophead, we LOVE this design, when building one the amount of thought that has gone into this design really shows. The only real way to experience this is to put one together - everything just makes excellent design sense. I especially recommend his blog post entitled Mendel90 axes [hydraraptor.blogspot.co.uk]

Here is our latest build:

(Bit of a plug - The machine pictured is for sale here: [forums.reprap.org] )

First thing we noticed was how much more easily built this machine is than a threaded rod design. The 4 sheets fix together in a jiffy and the axes simply screw onto those. No aligning needed, no spinning nuts hundreds of mm along stud, no putting the frame together then realising you forgot a washer somewhere so have to take it all down to get it on. Things fix to and come off the sheets in seconds, all you have to get precisely right is a few simply right angled cuts. This also makes modding/maintaining/making changes really fast and easy.

Faults are quite easily found, you can get your head right in the machine with the open frame and see what's really going on.

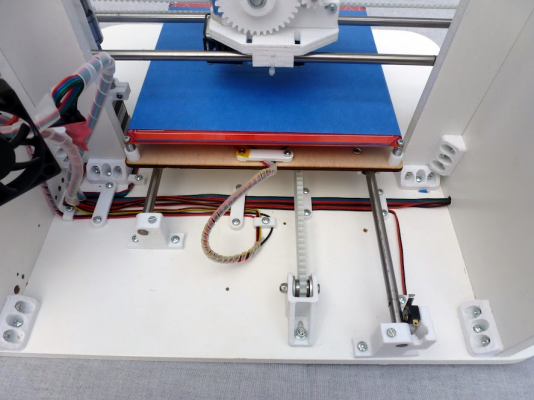

The sheet also makes routing cabling really trivial, just screw it down to the sheets with printed clips as you like. It also means adding bits, mounting PCBs etc is similarly trivial. We intend to add a click-encoder and LCD screen controller in time, placing parts like this is dead simple.

Nice easy tidy cable management

The use of ribbon cable is fantastic! Do go for the proper multi-core rainbow coloured stuff, it takes a shocking amount of current (2A/strand) and makes organising what wires go where almost pleasurable! It loops really nicely to the moving axes and seems to enforce its own minimum bend radius quite nicely.

What to make the sheets of is an interesting question. We started with 12mm MDF, this works well mechanically, very strong!

We can stand on our machine!

We seal our MDF sheets with MDF sealant, and add a coat of paint to make it pretty. All fine, but all those coats of paint and dry time adds a non-trivial amount of effort. We looked at acrylic/plexiglass sheet, its certainly pretty, but it scratches, cracks and splits from experience. It is also very expensive compared to MDF. We've been looking at various sheet materials and been to some sheet plastic warehouses, what we have identified and are switching to is rigid pressed PVC sheeting (9mm), this is incredibly durable feeling stuff, super rigid and strong. It should take woodscrews with a pilot hole for a very strong hold, or can be tapped for machine screws. It's also heavy, which is a double edged sword with regards to portability vs stability. Price is quite good, we can get 4-5 machines out of an £80 sheet, so £16-20 a machine.

With regards to the printed parts, some could be quite challenging if you struggle with bridges - the X-motor-mount has some pretty big bridges going on. We printed our machines in PLA and this works just fine, even though I think nophead had ABS in mind. We sliced all our parts with slic3r, there were some issues, but I don't regret going slic3r over skeinforge.

Caveats! - The tiny parts that clamp the belt to the Y-Belt-Anchors are non-manifold according to slic3r, at least in the STL supplied in the 'printed' folder of the mendel branch from github. - They slice wrongly, and somehow seem to 'infect' other parts in the plate. This is solved by printing them separately from their individual STLs and not the supplied plates. No big deal, but odd? Is this a slic3r bug or a bad SCAD export?

Secondly, slic3r 0.8.4 handles holes and insides of arcs etc differently it seems, making holes smaller. This manifests itself quite insidiously and subtly - causing the inside of the C-clamp that holds the Z axis LM8UU's to be printed slightly too tight. - This in turn causes the LM8UU to sit slightly too spaced away from the nut-trap, which makes the Z-Threaded-rods and the Z silver steel sit out of parallel, slightly. This problem took a long time to track down!

We have switched from M8 Stud for the Z axis to M5 stud, this lets us couple the 5mm motor shaft to the M5 stud with just some vinyl tubing pushed over each and tightened with a jubilee clip. This gives great flexible coupling and eliminates Z wobble. It also gives you more E-steps/mm on Z at the expense of feedrate.

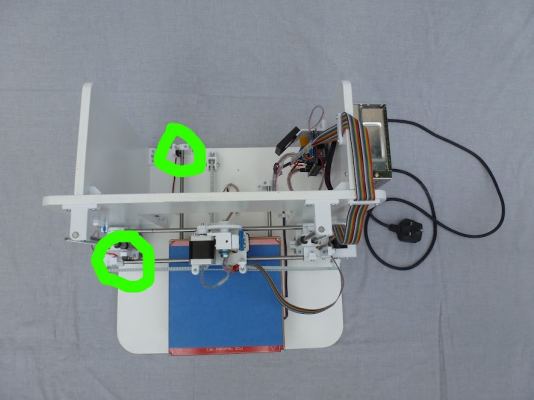

Due to nophead using slightly different homing setup on his custom electronics we have rearranged the endstops a little, to get the home position to be bottom-left-front as most reprap software expects. We do this by arranging the Y bar clamps so the switch is at the back. and we have taken then homing switch off the X-motor-housing, and added a place for it on the X-Idler. We'll get the STLs for this little mod on thingiverse soon.

New EndStop Positions Circled

Out of cheapness/convenience we have consolidated fixing hardware to pozi-drive pan head machine screws and strayed from the prescribed BOM a little. Some things are a little awkward to do up, but its quite manageable really. One change we did have to make due to this stems from the fact that it is impossible to do up the bar-clamp of the X-ends nearest the frame. To get around this we just drilled an 8mm hole through the gantry through which you can poke a screwdriver to reach the screw that tightens that bar-clamp.

Right, it's getting late, and that's all I can think of!

Next post will be on our hot-end - All metal, no PTFE/PEEK, just brass, A2 stainless and aluminium, very strong, simple and should hit obscene temperatures for polycarbonate etc. It's a beauty!

Firstly, a big thank-you to Nophead, we LOVE this design, when building one the amount of thought that has gone into this design really shows. The only real way to experience this is to put one together - everything just makes excellent design sense. I especially recommend his blog post entitled Mendel90 axes [hydraraptor.blogspot.co.uk]

Here is our latest build:

(Bit of a plug - The machine pictured is for sale here: [forums.reprap.org] )

First thing we noticed was how much more easily built this machine is than a threaded rod design. The 4 sheets fix together in a jiffy and the axes simply screw onto those. No aligning needed, no spinning nuts hundreds of mm along stud, no putting the frame together then realising you forgot a washer somewhere so have to take it all down to get it on. Things fix to and come off the sheets in seconds, all you have to get precisely right is a few simply right angled cuts. This also makes modding/maintaining/making changes really fast and easy.

Faults are quite easily found, you can get your head right in the machine with the open frame and see what's really going on.

The sheet also makes routing cabling really trivial, just screw it down to the sheets with printed clips as you like. It also means adding bits, mounting PCBs etc is similarly trivial. We intend to add a click-encoder and LCD screen controller in time, placing parts like this is dead simple.

Nice easy tidy cable management

The use of ribbon cable is fantastic! Do go for the proper multi-core rainbow coloured stuff, it takes a shocking amount of current (2A/strand) and makes organising what wires go where almost pleasurable! It loops really nicely to the moving axes and seems to enforce its own minimum bend radius quite nicely.

What to make the sheets of is an interesting question. We started with 12mm MDF, this works well mechanically, very strong!

We can stand on our machine!

We seal our MDF sheets with MDF sealant, and add a coat of paint to make it pretty. All fine, but all those coats of paint and dry time adds a non-trivial amount of effort. We looked at acrylic/plexiglass sheet, its certainly pretty, but it scratches, cracks and splits from experience. It is also very expensive compared to MDF. We've been looking at various sheet materials and been to some sheet plastic warehouses, what we have identified and are switching to is rigid pressed PVC sheeting (9mm), this is incredibly durable feeling stuff, super rigid and strong. It should take woodscrews with a pilot hole for a very strong hold, or can be tapped for machine screws. It's also heavy, which is a double edged sword with regards to portability vs stability. Price is quite good, we can get 4-5 machines out of an £80 sheet, so £16-20 a machine.

With regards to the printed parts, some could be quite challenging if you struggle with bridges - the X-motor-mount has some pretty big bridges going on. We printed our machines in PLA and this works just fine, even though I think nophead had ABS in mind. We sliced all our parts with slic3r, there were some issues, but I don't regret going slic3r over skeinforge.

Caveats! - The tiny parts that clamp the belt to the Y-Belt-Anchors are non-manifold according to slic3r, at least in the STL supplied in the 'printed' folder of the mendel branch from github. - They slice wrongly, and somehow seem to 'infect' other parts in the plate. This is solved by printing them separately from their individual STLs and not the supplied plates. No big deal, but odd? Is this a slic3r bug or a bad SCAD export?

Secondly, slic3r 0.8.4 handles holes and insides of arcs etc differently it seems, making holes smaller. This manifests itself quite insidiously and subtly - causing the inside of the C-clamp that holds the Z axis LM8UU's to be printed slightly too tight. - This in turn causes the LM8UU to sit slightly too spaced away from the nut-trap, which makes the Z-Threaded-rods and the Z silver steel sit out of parallel, slightly. This problem took a long time to track down!

We have switched from M8 Stud for the Z axis to M5 stud, this lets us couple the 5mm motor shaft to the M5 stud with just some vinyl tubing pushed over each and tightened with a jubilee clip. This gives great flexible coupling and eliminates Z wobble. It also gives you more E-steps/mm on Z at the expense of feedrate.

Due to nophead using slightly different homing setup on his custom electronics we have rearranged the endstops a little, to get the home position to be bottom-left-front as most reprap software expects. We do this by arranging the Y bar clamps so the switch is at the back. and we have taken then homing switch off the X-motor-housing, and added a place for it on the X-Idler. We'll get the STLs for this little mod on thingiverse soon.

New EndStop Positions Circled

Out of cheapness/convenience we have consolidated fixing hardware to pozi-drive pan head machine screws and strayed from the prescribed BOM a little. Some things are a little awkward to do up, but its quite manageable really. One change we did have to make due to this stems from the fact that it is impossible to do up the bar-clamp of the X-ends nearest the frame. To get around this we just drilled an 8mm hole through the gantry through which you can poke a screwdriver to reach the screw that tightens that bar-clamp.

Right, it's getting late, and that's all I can think of!

Next post will be on our hot-end - All metal, no PTFE/PEEK, just brass, A2 stainless and aluminium, very strong, simple and should hit obscene temperatures for polycarbonate etc. It's a beauty!

|

Re: Our Mendel90 Build Experience and Mods July 17, 2012 09:09PM |

Registered: 11 years ago Posts: 1,277 |

I love your write up and your work is phenomenal and something I am following though "my friend and I have been bitten by the RepRap bug" as well though we aren't ready yet to fully dive in (I want Nema 23 steppers and all I see are Nema 17 which I do not want). A lot of work but if done well and tweaked I bet some great prints will be made. Now trying to keep costs down will be the hardest part.

Keep up the good work.

Keep up the good work.

|

Re: Our Mendel90 Build Experience and Mods July 17, 2012 11:52PM |

Registered: 14 years ago Posts: 177 |

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 05:01AM |

Admin Registered: 17 years ago Posts: 7,879 |

I notice you haven't used the ribbon cable for the bed. I believe the arrangement you have used, with a thick cable and nothing to stop it flexing were it meets the carriage will lead to it burning eventually. I have had a couple cables burn doing that. What happens is when you have a thick cable it needs a much bigger minimum bend radius. I think it is a cube or fourth power law. If that is not enforced over the full length of the cable you get more bending at the ends. The strands break one by one and the remaining ones then overheat and melt / burn the insulation.

The ribbon cable is many many times more flexible but I also recommend the polypropylene strips. Without them it will bend more at the ends than the middle and this effect multiplies as the flexing weakens the bit that flexes most. It may look fine at the moment but I have run machines 24/7 for a couple of years and that is when these things start to fail.

> With regards to the printed parts, some could be

> quite challenging if you struggle with bridges -

> the X-motor-mount has some pretty big bridges going on.

I have a new version of that part with a removable support structure that I will release soon.

>

> Caveats! - The tiny parts that clamp the belt to

> the Y-Belt-Anchors are non-manifold according to

> slic3r, at least in the STL supplied in the

> 'printed' folder of the mendel branch from github.

> - They slice wrongly, and somehow seem to 'infect'

> other parts in the plate.

According to Netfabb it is the anchors themselves, not the clips, that are non-manifold. It is due to the edge of the nut trap being coincident with the face of the webs. Again that is fixed and will be in the new release.

> Secondly, slic3r 0.8.4 handles holes and insides

> of arcs etc differently it seems, making holes

> smaller. This manifests itself quite insidiously

> and subtly - causing the inside of the C-clamp

> that holds the Z axis LM8UU's to be printed

> slightly too tight. - This in turn causes the

> LM8UU to sit slightly too spaced away from the

> nut-trap, which makes the Z-Threaded-rods and the

> Z silver steel sit out of parallel, slightly. This

> problem took a long time to track down!

I would not use Slice3r for anything that has to be geometrically correct at the moment. Skeinforge has been getting this right for years now.

> Due to nophead using slightly different homing

> setup on his custom electronics we have rearranged

> the endstops a little, to get the home position to

> be bottom-left-front as most reprap software

> expects. We do this by arranging the Y bar clamps

> so the switch is at the back. and we have taken

> then homing switch off the X-motor-housing, and

> added a place for it on the X-Idler. We'll get the

> STLs for this little mod on thingiverse soon.

The original scheme works fine with standard electronics and firmware and avoids a set of wires to the idler end. All it means is the front of the machine is actually the back. Alternatively the firmware can be configured as having max endstops instead of min.

> Next post will be on our hot-end - All metal, no

> PTFE/PEEK, just brass, A2 stainless and aluminium,

> very strong, simple and should hit obscene

> temperatures for polycarbonate etc. It's a beauty!

>

I look forward to seeing that as I also think all metal is the way to go and in fact pioneered it many moons ago.

[www.hydraraptor.blogspot.com]

The ribbon cable is many many times more flexible but I also recommend the polypropylene strips. Without them it will bend more at the ends than the middle and this effect multiplies as the flexing weakens the bit that flexes most. It may look fine at the moment but I have run machines 24/7 for a couple of years and that is when these things start to fail.

> With regards to the printed parts, some could be

> quite challenging if you struggle with bridges -

> the X-motor-mount has some pretty big bridges going on.

I have a new version of that part with a removable support structure that I will release soon.

>

> Caveats! - The tiny parts that clamp the belt to

> the Y-Belt-Anchors are non-manifold according to

> slic3r, at least in the STL supplied in the

> 'printed' folder of the mendel branch from github.

> - They slice wrongly, and somehow seem to 'infect'

> other parts in the plate.

According to Netfabb it is the anchors themselves, not the clips, that are non-manifold. It is due to the edge of the nut trap being coincident with the face of the webs. Again that is fixed and will be in the new release.

> Secondly, slic3r 0.8.4 handles holes and insides

> of arcs etc differently it seems, making holes

> smaller. This manifests itself quite insidiously

> and subtly - causing the inside of the C-clamp

> that holds the Z axis LM8UU's to be printed

> slightly too tight. - This in turn causes the

> LM8UU to sit slightly too spaced away from the

> nut-trap, which makes the Z-Threaded-rods and the

> Z silver steel sit out of parallel, slightly. This

> problem took a long time to track down!

I would not use Slice3r for anything that has to be geometrically correct at the moment. Skeinforge has been getting this right for years now.

> Due to nophead using slightly different homing

> setup on his custom electronics we have rearranged

> the endstops a little, to get the home position to

> be bottom-left-front as most reprap software

> expects. We do this by arranging the Y bar clamps

> so the switch is at the back. and we have taken

> then homing switch off the X-motor-housing, and

> added a place for it on the X-Idler. We'll get the

> STLs for this little mod on thingiverse soon.

The original scheme works fine with standard electronics and firmware and avoids a set of wires to the idler end. All it means is the front of the machine is actually the back. Alternatively the firmware can be configured as having max endstops instead of min.

> Next post will be on our hot-end - All metal, no

> PTFE/PEEK, just brass, A2 stainless and aluminium,

> very strong, simple and should hit obscene

> temperatures for polycarbonate etc. It's a beauty!

>

I look forward to seeing that as I also think all metal is the way to go and in fact pioneered it many moons ago.

[www.hydraraptor.blogspot.com]

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 05:08AM |

Admin Registered: 17 years ago Posts: 7,879 |

Dark Alchemist Wrote:

-------------------------------------------------------

> I love your write up and your work is phenomenal

> and something I am following though "my friend and

> I have been bitten by the RepRap bug" as well

> though we aren't ready yet to fully dive in (I

> want Nema 23 steppers and all I see are Nema 17

> which I do not want). A lot of work but if done

> well and tweaked I bet some great prints will be

> made. Now trying to keep costs down will be the

> hardest part.

>

> Keep up the good work.

Mendel90 is parametric so no problem mechanically to use NEMA23. Just put the size in stepper-motors.scad, make a new config and rebuild. It will adjust all the STLs and DXFs.

The main problem will be the electronics to get enough current without it being a lot more expensive. GEN7T is probably the best bet but is a bit experimental at the moment. I am not sure why you want NEMA23 though, the NEMA17's have plenty of torque for the job.

[www.hydraraptor.blogspot.com]

-------------------------------------------------------

> I love your write up and your work is phenomenal

> and something I am following though "my friend and

> I have been bitten by the RepRap bug" as well

> though we aren't ready yet to fully dive in (I

> want Nema 23 steppers and all I see are Nema 17

> which I do not want). A lot of work but if done

> well and tweaked I bet some great prints will be

> made. Now trying to keep costs down will be the

> hardest part.

>

> Keep up the good work.

Mendel90 is parametric so no problem mechanically to use NEMA23. Just put the size in stepper-motors.scad, make a new config and rebuild. It will adjust all the STLs and DXFs.

The main problem will be the electronics to get enough current without it being a lot more expensive. GEN7T is probably the best bet but is a bit experimental at the moment. I am not sure why you want NEMA23 though, the NEMA17's have plenty of torque for the job.

[www.hydraraptor.blogspot.com]

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 06:05AM |

Registered: 11 years ago Posts: 1,277 |

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 11:53AM |

Registered: 12 years ago Posts: 939 |

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 01:07PM |

Registered: 14 years ago Posts: 177 |

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 02:21PM |

Registered: 11 years ago Posts: 1,277 |

Polygonhell Wrote:

-------------------------------------------------------

> I think you'd want to stick with a nem17 for the

> extruder at least unless yo go to a bowden type

> design. 23's tend to be a lot heavier so you'd be

> significantly increasing the mass of the X axis

> for no real gain.

23's make the CNC move fast as all get out and they don't even get warm but the 17's have a bad issue with getting overly hot for the extruder and I see people put a fan for the head (for obvious reasons) and one (or a heatsink/fan combo) on the 17 extruder stepper due to it getting so hot it warps the plastic parts.

Anyway which 17 do people use for the extruder?

-------------------------------------------------------

> I think you'd want to stick with a nem17 for the

> extruder at least unless yo go to a bowden type

> design. 23's tend to be a lot heavier so you'd be

> significantly increasing the mass of the X axis

> for no real gain.

23's make the CNC move fast as all get out and they don't even get warm but the 17's have a bad issue with getting overly hot for the extruder and I see people put a fan for the head (for obvious reasons) and one (or a heatsink/fan combo) on the 17 extruder stepper due to it getting so hot it warps the plastic parts.

Anyway which 17 do people use for the extruder?

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 02:33PM |

Registered: 13 years ago Posts: 818 |

Very Nice build, good job.

I'm very tempted to make one up - Is anyone selling cut Acrylic or PC sheets for Mendel90 yet?

Anyone scaled it down? Huxley Sized? would make a great portable machine.

[richrap.blogspot.com]

I'm very tempted to make one up - Is anyone selling cut Acrylic or PC sheets for Mendel90 yet?

Anyone scaled it down? Huxley Sized? would make a great portable machine.

[richrap.blogspot.com]

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 04:15PM |

Registered: 12 years ago Posts: 177 |

Hi Rich,

We can sell you a fully cut/drilled frame in extremely rigid pressed PVC sheet. We have just put together a frame in the last 30 minutes from it, and it's awesome stuff. Quite heavy, but reassuringly so. You can screw into it with woodscrews without it cracking even with incredible torque.

By the time it's CNC cut etc it isnt that cheap, but in the same range as acrylic etc. It is however a much better material than acrylic. Probably £40ish - and that's without us marking it up at all. Happy to sell it at cost to you - would love to see a Mendel90 up on your blog, we think it would give the MendelMax a run for its money.

We can also source and cut the DiBond bed sheet for about a £10, we really love the DiBond beds for the weight and rigidity. - Both frame and Dibond would be white.

Let us know!

We can sell you a fully cut/drilled frame in extremely rigid pressed PVC sheet. We have just put together a frame in the last 30 minutes from it, and it's awesome stuff. Quite heavy, but reassuringly so. You can screw into it with woodscrews without it cracking even with incredible torque.

By the time it's CNC cut etc it isnt that cheap, but in the same range as acrylic etc. It is however a much better material than acrylic. Probably £40ish - and that's without us marking it up at all. Happy to sell it at cost to you - would love to see a Mendel90 up on your blog, we think it would give the MendelMax a run for its money.

We can also source and cut the DiBond bed sheet for about a £10, we really love the DiBond beds for the weight and rigidity. - Both frame and Dibond would be white.

Let us know!

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 05:42PM |

Registered: 12 years ago Posts: 313 |

SanjayM Wrote:

-------------------------------------------------------

> First thing we noticed was how much more easily

> built this machine is than a threaded rod design.

> The 4 sheets fix together in a jiffy and the axes

> simply screw onto those. No aligning needed ...

But this is after you either happen to own a pretty fancy workshop or had the sheets custom made for yourself somewhere? And if you're building your machine quite literally on the kitchen table, you're out of luck unless you want to pay to get the sheets cut and accurately drilled?

I have read the exact same boasting for MendelMax - so easy to put together! After you have obtained a bunch of hard to find custom made parts... (I looked around and could not find MendelMax frame parts for sale to private individuals anywhere, not to my country anyway)

-------------------------------------------------------

> First thing we noticed was how much more easily

> built this machine is than a threaded rod design.

> The 4 sheets fix together in a jiffy and the axes

> simply screw onto those. No aligning needed ...

But this is after you either happen to own a pretty fancy workshop or had the sheets custom made for yourself somewhere? And if you're building your machine quite literally on the kitchen table, you're out of luck unless you want to pay to get the sheets cut and accurately drilled?

I have read the exact same boasting for MendelMax - so easy to put together! After you have obtained a bunch of hard to find custom made parts... (I looked around and could not find MendelMax frame parts for sale to private individuals anywhere, not to my country anyway)

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 07:22PM |

Registered: 13 years ago Posts: 248 |

It does look very well in white. The Mendel 90 is climbing high on my 'next printer' list!

I like the sound of that PVC sheet. If you are getting it CNC cut then you could get a simple handle cut into the top cross piece. Not sure it's a portable size, but it would make it easier to lug around if you needed to.

I'm also delighted to hear NopHead is continuing to evolve the design of the parts. That x-motor box looks like a right printing/bridging challenge.

Personally, I'd probably position the y-motor to the rear, if only for cosmetic reasons, giving a cleaner line to the front of the machine. It would put the y-belt adjustment where you could get at it more easily also. Any technical reason why the y-motor couldn't go at the rear?

I look forward to seeing your stainless-insulator hotend. The Mendel90 x-carriage has no specific fan mounting locations on it. I'll be interested to see how you position cooling for your hot-end, and whether you plan to adapt the x-carriage or redesign it in any way.

Best of luck with your venture.

NumberSix

[numbersixreprap.blogspot.com]

I like the sound of that PVC sheet. If you are getting it CNC cut then you could get a simple handle cut into the top cross piece. Not sure it's a portable size, but it would make it easier to lug around if you needed to.

I'm also delighted to hear NopHead is continuing to evolve the design of the parts. That x-motor box looks like a right printing/bridging challenge.

Personally, I'd probably position the y-motor to the rear, if only for cosmetic reasons, giving a cleaner line to the front of the machine. It would put the y-belt adjustment where you could get at it more easily also. Any technical reason why the y-motor couldn't go at the rear?

I look forward to seeing your stainless-insulator hotend. The Mendel90 x-carriage has no specific fan mounting locations on it. I'll be interested to see how you position cooling for your hot-end, and whether you plan to adapt the x-carriage or redesign it in any way.

Best of luck with your venture.

NumberSix

[numbersixreprap.blogspot.com]

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 08:11PM |

Admin Registered: 17 years ago Posts: 7,879 |

@ttsalo,

Which country are you in? Do you have a local DIY shop that cut sheets to size? The holes can be drilled with paper templates from a 2D printer and a hand drill. That is how I made two of my machines.

I will be selling sheets soon. I am just updating the design at the moment,

Edited 1 time(s). Last edit at 07/18/2012 08:20PM by nophead.

[www.hydraraptor.blogspot.com]

Which country are you in? Do you have a local DIY shop that cut sheets to size? The holes can be drilled with paper templates from a 2D printer and a hand drill. That is how I made two of my machines.

I will be selling sheets soon. I am just updating the design at the moment,

Edited 1 time(s). Last edit at 07/18/2012 08:20PM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 08:14PM |

Registered: 12 years ago Posts: 147 |

ttsalo Wrote:

-------------------------------------------------------

> But this is after you either happen to own a

> pretty fancy workshop or had the sheets custom

> made for yourself somewhere? And if you're

> building your machine quite literally on the

> kitchen table, you're out of luck unless you want

> to pay to get the sheets cut and accurately

> drilled?

>

> I have read the exact same boasting for MendelMax

> - so easy to put together! After you have obtained

> a bunch of hard to find custom made parts... (I

> looked around and could not find MendelMax frame

> parts for sale to private individuals anywhere,

> not to my country anyway)

There are no custom parts required (over a Prusa Mendel) and using Misumi branded extrusions is just a suggestion, there are heaps of alternatives for most countries.

For the Mendel90, I don't know what Nophead's suggestions are but it doesn't strike me as a design that requires any CNC or even a pillar drill. The frame looks as if it can be printed on paper or marked out by hand and drilled with a hand drill. Alignment may become an issue but I'm sure Nophead has addressed that in his design.

-------------------------------------------------------

> But this is after you either happen to own a

> pretty fancy workshop or had the sheets custom

> made for yourself somewhere? And if you're

> building your machine quite literally on the

> kitchen table, you're out of luck unless you want

> to pay to get the sheets cut and accurately

> drilled?

>

> I have read the exact same boasting for MendelMax

> - so easy to put together! After you have obtained

> a bunch of hard to find custom made parts... (I

> looked around and could not find MendelMax frame

> parts for sale to private individuals anywhere,

> not to my country anyway)

There are no custom parts required (over a Prusa Mendel) and using Misumi branded extrusions is just a suggestion, there are heaps of alternatives for most countries.

For the Mendel90, I don't know what Nophead's suggestions are but it doesn't strike me as a design that requires any CNC or even a pillar drill. The frame looks as if it can be printed on paper or marked out by hand and drilled with a hand drill. Alignment may become an issue but I'm sure Nophead has addressed that in his design.

|

Re: Our Mendel90 Build Experience and Mods July 18, 2012 08:26PM |

Admin Registered: 17 years ago Posts: 7,879 |

@NumberSix,

I think the Y motor would clash with the bed wiring if it was at the back. The bed wiring could be moved to the front but I think that looks more messy than the motor,

[www.hydraraptor.blogspot.com]

I think the Y motor would clash with the bed wiring if it was at the back. The bed wiring could be moved to the front but I think that looks more messy than the motor,

[www.hydraraptor.blogspot.com]

|

Re: Our Mendel90 Build Experience and Mods July 21, 2012 01:07PM |

Registered: 11 years ago Posts: 120 |

|

Re: Our Mendel90 Build Experience and Mods July 21, 2012 04:20PM |

Admin Registered: 17 years ago Posts: 7,879 |

Yes but I use two wires for the heater power and ground as the grey wire is rated at 1.4A per wire and the heater is about 2A.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Our Mendel90 Build Experience and Mods July 22, 2012 05:57AM |

Registered: 11 years ago Posts: 120 |

|

Re: Our Mendel90 Build Experience and Mods July 22, 2012 06:09AM |

Admin Registered: 17 years ago Posts: 7,879 |

This is the way I allocate the wires for minimum crosstalk [reprap.org].

I am thinking of switching to a 15 way IDC D connector to avoid the need to solder. For some reason IDC connectors are about 5 times more expensive than solder bucket.

[www.hydraraptor.blogspot.com]

I am thinking of switching to a 15 way IDC D connector to avoid the need to solder. For some reason IDC connectors are about 5 times more expensive than solder bucket.

[www.hydraraptor.blogspot.com]

|

Re: Our Mendel90 Build Experience and Mods July 24, 2012 07:36PM |

Registered: 12 years ago Posts: 177 |

|

Re: Our Mendel90 Build Experience and Mods July 25, 2012 08:09AM |

Registered: 14 years ago Posts: 3,742 |

Dark Alchemist Wrote:

-------------------------------------------------------

> I have the Nema 23's already and no Nema 17's from

> my CNC project. My problem is getting the mounts

> for the 23's as everything I have seen on the net

> has the mounting for 17 and not 23.

Take a look at Andis PowerMendel.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

-------------------------------------------------------

> I have the Nema 23's already and no Nema 17's from

> my CNC project. My problem is getting the mounts

> for the 23's as everything I have seen on the net

> has the mounting for 17 and not 23.

Take a look at Andis PowerMendel.

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: Our Mendel90 Build Experience and Mods July 25, 2012 08:27AM |

Registered: 11 years ago Posts: 1,277 |

rhmorrison Wrote:

-------------------------------------------------------

> Dark Alchemist Wrote:

> --------------------------------------------------

> -----

> > I have the Nema 23's already and no Nema 17's

> from

> > my CNC project. My problem is getting the

> mounts

> > for the 23's as everything I have seen on the

> net

> > has the mounting for 17 and not 23.

>

> Take a look at Andis PowerMendel.

Google translator here I come.

edit: Rock on but it takes a Mendel to make that.

Edited 1 time(s). Last edit at 07/25/2012 08:29AM by Dark Alchemist.

-------------------------------------------------------

> Dark Alchemist Wrote:

> --------------------------------------------------

> -----

> > I have the Nema 23's already and no Nema 17's

> from

> > my CNC project. My problem is getting the

> mounts

> > for the 23's as everything I have seen on the

> net

> > has the mounting for 17 and not 23.

>

> Take a look at Andis PowerMendel.

Google translator here I come.

edit: Rock on but it takes a Mendel to make that.

Edited 1 time(s). Last edit at 07/25/2012 08:29AM by Dark Alchemist.

|

Re: Our Mendel90 Build Experience and Mods July 25, 2012 08:32AM |

Registered: 14 years ago Posts: 3,742 |

|

Re: Our Mendel90 Build Experience and Mods July 25, 2012 09:23AM |

Registered: 11 years ago Posts: 1,277 |

rhmorrison Wrote:

-------------------------------------------------------

> > Rock on but it takes a Mendel to make that.

>

>

> YES, that is Catch-22 for RepRappers!

Aye, but that doesn't do me any good if I have to go out and purchase NEMA 17's to get it done.

No biggie I have ideas where I will not need a RepRap to make my first RepRap so no conundrum and the causality loop has been broken.

-------------------------------------------------------

> > Rock on but it takes a Mendel to make that.

>

>

> YES, that is Catch-22 for RepRappers!

Aye, but that doesn't do me any good if I have to go out and purchase NEMA 17's to get it done.

No biggie I have ideas where I will not need a RepRap to make my first RepRap so no conundrum and the causality loop has been broken.

|

Re: Our Mendel90 Build Experience and Mods July 28, 2012 09:38AM |

Registered: 12 years ago Posts: 177 |

|

Re: Our Mendel90 Build Experience and Mods July 29, 2012 06:22AM |

Registered: 11 years ago Posts: 1,277 |

Sorry, only registered users may post in this forum.