Printing Actual PCBs Without Etching

Posted by Lodorenos

|

Printing Actual PCBs Without Etching August 14, 2012 05:56AM |

Registered: 11 years ago Posts: 83 |

After reading a topic about an all metal hotend capable of reaching 325'C+, I came up with this idea. It may have been thought of before, but I was unable to find it mentioned anywhere: Printing complete PCBs without needing to etch the board afterwards.

To start off, a PCB needs at least two types of material to function properly:

- A conductive material for traces

- An nonconducting board support material

With a hotend capable of 325'C+, you would need two materials with melting points under that temperature.

- Tin, a conductive metal, has a melting point 231.93°C

- PET(E), a nonconducting plastic with a melting point of about 250°C

Those two temperatures are extremely close together, and the fact that the conductive material has a lower melting point is a good thing.

Continuing on, you would need a printer with dual extruders for this to be possible. You would need to find a schematic of a PCB online or make one yourself. From that, create a 3D model of the board (a rectangle, a circle, a star, get creative) and add the traces. Use Skeinforge or another program capable of slicing for dual extrusion use, and set the board material to extruder 1, loaded with PETE, and the traces to the second extruder, which is loaded with tin.

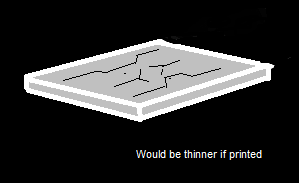

In theory, the PETE will not melt or deform when liquid tin is laid down on top of it because of its higher melting temperature. Warping should not be an issue as the entire print should not be more than several milimeters tall.

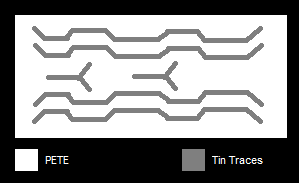

If this works, and I don't see a reason it wouldn't, the RepRap project could be one step closer to completely replicating itself. With current day RepRaps, specialty nozzles with a size of 0.35mm or less should be capable of printing very good quality traces. Included are some horrible images created in paint to make this idea more clear.

Problems that need solving:

1. 3mm PETE filament is not easily available. More research into self recycling (RecycleBot, FilaBot, etc) could fix this.

2. Printing in tin might be difficult, as a new type of extruder would need to be built or an existing one modified. I am uncertain at this point whether tin could be obtained in a filament or if an auger type extruder should be used to push scraps of tin into the hotend.

3. Dual extrusion is a relatively new topic, not many people are testing it, and problems are hard to fix. Creating a model to use dual extrusion requires some work as well.

Maybe someone could develop software to convert PCB schematics to 3D models?

Please give me your thoughts, critisism, and anything else you would like to share. Dual extrusion could open a very wide door to printing our own electronics.

On a side note, printed boards like this could actually be used if a low temperature solder iron and low temperature solder is used (available in the 150'C-200'C range).

Should a Wiki page be made with this idea? I would be happy to create and maintain it.

Edited 1 time(s). Last edit at 08/14/2012 06:08AM by Lodorenos.

--

Charles S.

Software Engineer

Prusa Mendel I2, RAMPS 1.4, Marlin 1.0 R2, Pronterface, Slic3r

To start off, a PCB needs at least two types of material to function properly:

- A conductive material for traces

- An nonconducting board support material

With a hotend capable of 325'C+, you would need two materials with melting points under that temperature.

- Tin, a conductive metal, has a melting point 231.93°C

- PET(E), a nonconducting plastic with a melting point of about 250°C

Those two temperatures are extremely close together, and the fact that the conductive material has a lower melting point is a good thing.

Continuing on, you would need a printer with dual extruders for this to be possible. You would need to find a schematic of a PCB online or make one yourself. From that, create a 3D model of the board (a rectangle, a circle, a star, get creative) and add the traces. Use Skeinforge or another program capable of slicing for dual extrusion use, and set the board material to extruder 1, loaded with PETE, and the traces to the second extruder, which is loaded with tin.

In theory, the PETE will not melt or deform when liquid tin is laid down on top of it because of its higher melting temperature. Warping should not be an issue as the entire print should not be more than several milimeters tall.

If this works, and I don't see a reason it wouldn't, the RepRap project could be one step closer to completely replicating itself. With current day RepRaps, specialty nozzles with a size of 0.35mm or less should be capable of printing very good quality traces. Included are some horrible images created in paint to make this idea more clear.

Problems that need solving:

1. 3mm PETE filament is not easily available. More research into self recycling (RecycleBot, FilaBot, etc) could fix this.

2. Printing in tin might be difficult, as a new type of extruder would need to be built or an existing one modified. I am uncertain at this point whether tin could be obtained in a filament or if an auger type extruder should be used to push scraps of tin into the hotend.

3. Dual extrusion is a relatively new topic, not many people are testing it, and problems are hard to fix. Creating a model to use dual extrusion requires some work as well.

Maybe someone could develop software to convert PCB schematics to 3D models?

Please give me your thoughts, critisism, and anything else you would like to share. Dual extrusion could open a very wide door to printing our own electronics.

On a side note, printed boards like this could actually be used if a low temperature solder iron and low temperature solder is used (available in the 150'C-200'C range).

Should a Wiki page be made with this idea? I would be happy to create and maintain it.

Edited 1 time(s). Last edit at 08/14/2012 06:08AM by Lodorenos.

--

Charles S.

Software Engineer

Prusa Mendel I2, RAMPS 1.4, Marlin 1.0 R2, Pronterface, Slic3r

|

Re: Printing Actual PCBs Without Etching August 14, 2012 06:13AM |

Admin Registered: 12 years ago Posts: 2,569 |

You might want to check on the reprap blog, some similar research already has been ongoing : [blog.reprap.org]

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

Most of my technical comments should be correct, but is THIS one ?

Anyway, as a rule of thumb, always double check what people write.

|

alagi

Re: Printing Actual PCBs Without Etching August 14, 2012 06:19AM |

I don't think you could extrude tin like you extrude the plastic (i.e. a filament). Tin is really soft even at room temperature, so you would need to develop a new type of extruder for it. (possibly auger as you also mention)

Why do you say 325C degrees? At what temperature should PET be extruded?

Why do you say 325C degrees? At what temperature should PET be extruded?

|

Re: Printing Actual PCBs Without Etching August 14, 2012 06:35AM |

Registered: 11 years ago Posts: 83 |

Sorry, only registered users may post in this forum.