Have to Keep Resetting Z Zero Position

Posted by ajayre

|

Have to Keep Resetting Z Zero Position August 27, 2012 03:17PM |

Registered: 11 years ago Posts: 172 |

I have found a clue as to why I am struggling to get PLA to stick to my glass heatbed, but I have no idea what to do next!

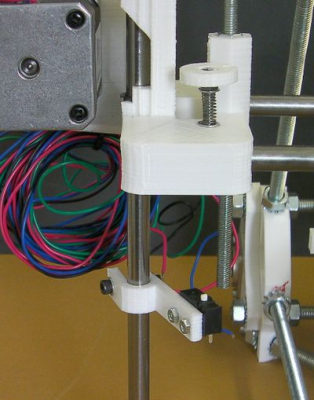

I have a RepRapPro Mendel which has a thumbwheel on the X axis gantry. This has a bolt tensioned with a spring. The end of the bolt hits the Z axis endstop microswitch [1].

The heatbed is leveled with three spring tensioned bolts.

I have set up the microswitch position, the three heatbed springs and the thumbwheel so that when Z is homed there is the thickness of a piece of paper between the print head and the bed in multiple places. I have put superglue on all the spings and thumbwheel.

When I print the first layer it is squished (80%) and it sticks.

After a couple of prints I find that the PLA no longer sticks. When I home Z I see that the gap between the print head and the bed is larger. A quick check shows that the gap is larger everywhere on the heatbed.

The thumbwheel has a mark on it and it hasn't moved.

I don't think the screws on the heatbed have moved. If they have then why would they tighten the springs up? If anything I would expect the springs to slacken and move the heatbed up.

Any ideas on what I can check next?

Should I remove the lever from the microswitch?

Thanks, Andy

[1] http://www.reprap.org/wiki/RepRapPro_Mendel_z_axis_assembly#Step_3:_The_adjustable_Z_endstop

Edited 2 time(s). Last edit at 08/27/2012 03:18PM by ajayre.

I have a RepRapPro Mendel which has a thumbwheel on the X axis gantry. This has a bolt tensioned with a spring. The end of the bolt hits the Z axis endstop microswitch [1].

The heatbed is leveled with three spring tensioned bolts.

I have set up the microswitch position, the three heatbed springs and the thumbwheel so that when Z is homed there is the thickness of a piece of paper between the print head and the bed in multiple places. I have put superglue on all the spings and thumbwheel.

When I print the first layer it is squished (80%) and it sticks.

After a couple of prints I find that the PLA no longer sticks. When I home Z I see that the gap between the print head and the bed is larger. A quick check shows that the gap is larger everywhere on the heatbed.

The thumbwheel has a mark on it and it hasn't moved.

I don't think the screws on the heatbed have moved. If they have then why would they tighten the springs up? If anything I would expect the springs to slacken and move the heatbed up.

Any ideas on what I can check next?

Should I remove the lever from the microswitch?

Thanks, Andy

[1] http://www.reprap.org/wiki/RepRapPro_Mendel_z_axis_assembly#Step_3:_The_adjustable_Z_endstop

Edited 2 time(s). Last edit at 08/27/2012 03:18PM by ajayre.

|

Re: Have to Keep Resetting Z Zero Position August 27, 2012 03:31PM |

Registered: 13 years ago Posts: 1,780 |

Did you adjust the clearance between the nozzle and the bed when they were at operating temperature? Usually, I find that the nozzle tend to move closer to the bed upon heating but your bed might move up or down depending on your set-up. I always adjust the clearance when everything is hot.

|

Re: Have to Keep Resetting Z Zero Position August 27, 2012 03:45PM |

Registered: 11 years ago Posts: 172 |

|

Re: Have to Keep Resetting Z Zero Position August 27, 2012 06:48PM |

Registered: 13 years ago Posts: 1,780 |

|

Re: Have to Keep Resetting Z Zero Position August 28, 2012 06:04AM |

Registered: 13 years ago Posts: 1,797 |

try putting another limit switch bracket below the one used. the second bracket is for support only. i had some issues with the bracket bending a little on my prusa printer. 2 inches out with a slight bend can offset start height by over 0.2mm. it does not take much to have calibration issues. my solution was to just glue it in place, it worked but if it needs to be replaced it will be a mess. also do not calibrate printer until it has been on and heated up for at least 2 minutes. this includes bed temp and nozzle temp. we want all parts that expand from temp to be where they would be during operation.

Sorry, only registered users may post in this forum.