Complete Bowden system! (even "Bowden" Fan)

Posted by zelogik

|

Complete Bowden system! (even "Bowden" Fan) June 09, 2013 04:50AM |

Registered: 11 years ago Posts: 225 |

Hello,

You have maybe already seen my own hbot 3D printer. In the case I want a full heated enclosure, cooling nozzle is not really efficient with simple Fan, and no efficient barrel cooling making always nozzle jams/problems .....

So the most common idea for the moment is watercooling... but water and electronic is not really pleasant for me, and you need pump, water tubing etc...

So If we can made bowden for filament, why not make the same with Fan and air flow.

I have two custom full metal hotend look like Qubd/makerbot mk7/prusa nozzle/E3D/... type.

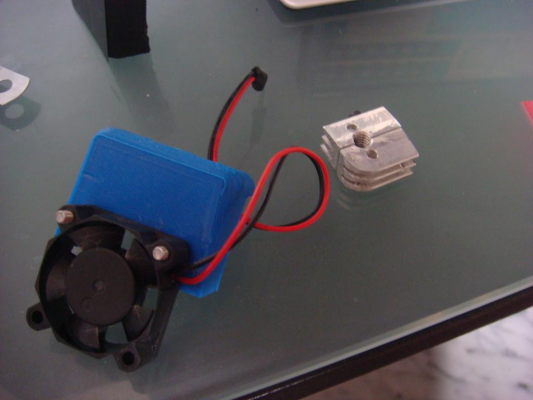

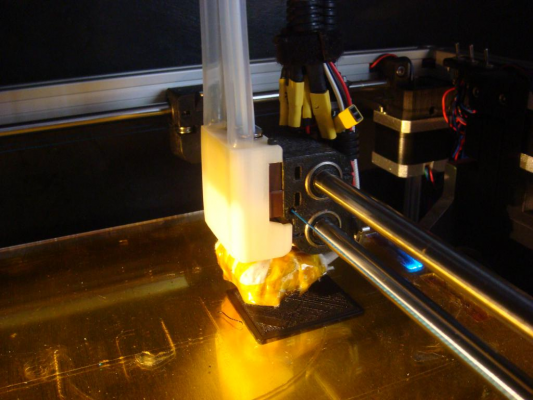

For the moment I have that installed on the stainless Steel Barrel for cooling it:

I have invested in 7530 blower fan and some cheap silicon Tubing:

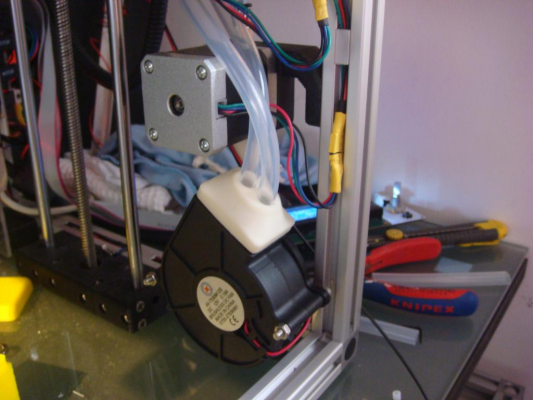

My Bowden Extruder with blower Fan installed below:

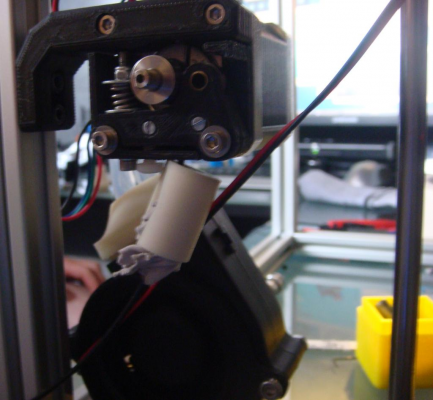

And made a sophisticate Stainless Steel Barrel full enclosure:

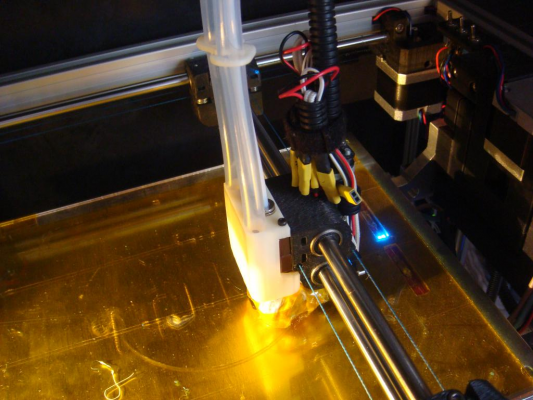

And it' work really well :-D

ie: The second advantage is than I have a little less warping with ABS (no more air flow from the fan on the part)

You have maybe already seen my own hbot 3D printer. In the case I want a full heated enclosure, cooling nozzle is not really efficient with simple Fan, and no efficient barrel cooling making always nozzle jams/problems .....

So the most common idea for the moment is watercooling... but water and electronic is not really pleasant for me, and you need pump, water tubing etc...

So If we can made bowden for filament, why not make the same with Fan and air flow.

I have two custom full metal hotend look like Qubd/makerbot mk7/prusa nozzle/E3D/... type.

For the moment I have that installed on the stainless Steel Barrel for cooling it:

I have invested in 7530 blower fan and some cheap silicon Tubing:

My Bowden Extruder with blower Fan installed below:

And made a sophisticate Stainless Steel Barrel full enclosure:

And it' work really well :-D

ie: The second advantage is than I have a little less warping with ABS (no more air flow from the fan on the part)

|

Re: Complete Bowden system! (even "Bowden" Fan) June 10, 2013 12:11AM |

Registered: 11 years ago Posts: 67 |

Stratasys uses a conduit to pipe in cool outside air into the heated case to cool the carriage as well, though theirs is a larger diameter tubing and doesn't have a return setup. I was considering doing similar and actually running the Bowden tubing and wires inside of a larger air tubing. Glad to a successful utilization.

|

Re: Complete Bowden system! (even "Bowden" Fan) June 10, 2013 06:29AM |

Registered: 11 years ago Posts: 225 |

Before I have thinking to make this setup with big and put everything inside: (like you have said)

But enter and exit are more difficult to draw with nice design. (ABS/Electrical/Air flow ....)

The most important is that I don't need heatSink on the stainless steel Barrel now, I think the cooling is really more efficient because you take fresh air and not "hot" air from the heated bed, I don't know why people are not interesting by this setup. :-D

But enter and exit are more difficult to draw with nice design. (ABS/Electrical/Air flow ....)

The most important is that I don't need heatSink on the stainless steel Barrel now, I think the cooling is really more efficient because you take fresh air and not "hot" air from the heated bed, I don't know why people are not interesting by this setup. :-D

|

Re: Complete Bowden system! (even "Bowden" Fan) June 10, 2013 07:09AM |

Registered: 13 years ago Posts: 1,797 |

I tried something like this a while ago, but was using 1/4 inch tubing. almost no air got thru using a fan. though of using an air pump from a fish tank. no matter what you will need pressurized flow to deliver the air current required for proper cooling. the issue with pressurized air is it changes the amount of moisture the air can hold. this will lead to drops of water going over the print.

I would think that a light fan would be the best method still, however what is needed I would guess is some data to prove how one works vs the other. until otherwise demonstrated, i would think the best air flow to still be from a fan directly over the pla/abs part it is cooling.

I would think that a light fan would be the best method still, however what is needed I would guess is some data to prove how one works vs the other. until otherwise demonstrated, i would think the best air flow to still be from a fan directly over the pla/abs part it is cooling.

|

Re: Complete Bowden system! (even "Bowden" Fan) June 10, 2013 07:45AM |

Registered: 11 years ago Posts: 225 |

What I have seen with my setup, is that one Fan blowing directly over the Stainless Steel Barrel is not enought efficient for keep a low temperature on it, I had to install heatsink on the barrel to have a better cooling (Like almost all full metal hotend doing now)

Now with this "small" box with fresh air flow , I don't need heatsink anymore. And i don't have experienced any jam on the nozzle for the moment.

I have a thermal Flir Camera at my job, I will try to test with fan and with cooling chamber to see witch one have the better thermal gradient (but it's difficult to seen inside the box ...)

Now with this "small" box with fresh air flow , I don't need heatsink anymore. And i don't have experienced any jam on the nozzle for the moment.

I have a thermal Flir Camera at my job, I will try to test with fan and with cooling chamber to see witch one have the better thermal gradient (but it's difficult to seen inside the box ...)

|

Re: Complete Bowden system! (even "Bowden" Fan) June 12, 2013 10:38AM |

Registered: 11 years ago Posts: 142 |

|

Re: Complete Bowden system! (even "Bowden" Fan) June 12, 2013 12:54PM |

Registered: 11 years ago Posts: 225 |

It's more noisy that a 40mm fan for sure. But i think the fan is too big for the silicon tubing size, so there is some perturbation at entrance who produce this noise.

But the noise is less annoying than the stepper frequency of motor.

I can now print with PLA. With fan and heatsink i can only extrude 10mm of pla before jamming. Now there is no jam anymore with pla :-)

So there is a full metal hotend who can print pla,ABS,nylon, ...

But the noise is less annoying than the stepper frequency of motor.

I can now print with PLA. With fan and heatsink i can only extrude 10mm of pla before jamming. Now there is no jam anymore with pla :-)

So there is a full metal hotend who can print pla,ABS,nylon, ...

Sorry, only registered users may post in this forum.