Getting over extrusion at perimeter edges

Posted by Gibbedy

|

Getting over extrusion at perimeter edges July 23, 2013 07:57AM |

Registered: 12 years ago Posts: 86 |

Since day one I have had an issue with my printers extrusion and have posted here several times.

In order to solve this problem I am going to calibrate again in the hope that someone will be able to help me with this.

I am attempting to calibrate a prusa i1 with jhead MKIV-B hotend, 3mm, PLA.

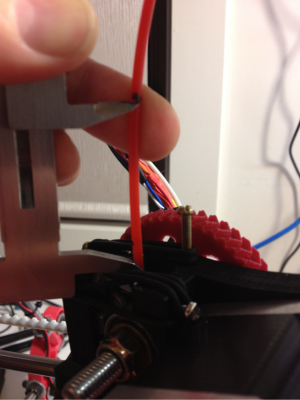

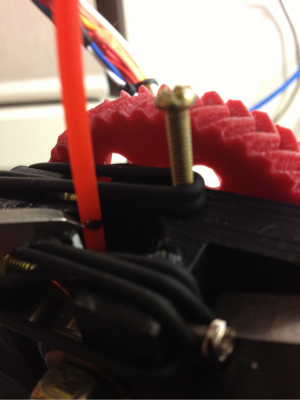

Measure 50mm of filament with vernier from top of extruder:

Extrude 50mm in pronterface and expect to see mark flush with the top of the extruder:

At this point I am happy that my e-steps are correct.

Next I slic3 up a .5mm thin wall at .4 layer height:

I measure .57mm wall width (top couple of layers). Gcode says it should be .53mm.

I reduce e multiplier from 1 to .92 in slic3r and print again to get correct .53mm measurement

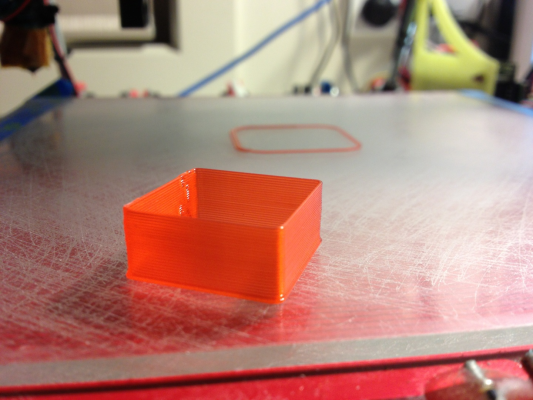

Next I print a 20mm cube:

This measures 19.6 x 19.7 at the centers. (I'm not sure if this is an issue?)

This print looks good however infill produces bumps at the perimeter edges. This is a problem where the hotend has to do a travel move over this infill. On a larger print it is constantly making a noise where the hotend jumps over these bumps and can lead to jams.

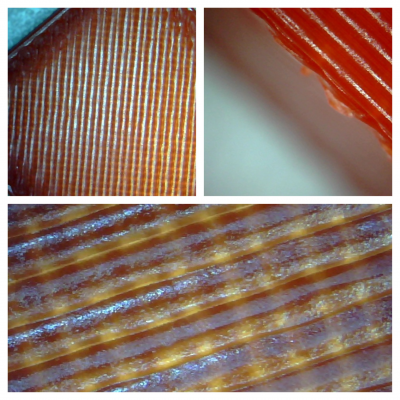

Edit:Clockwise from top left, top of cube (correct layer width),side of cube (see bumps that cause problems), top of cube (close up).

Click here if you don't see a 3 pic image above

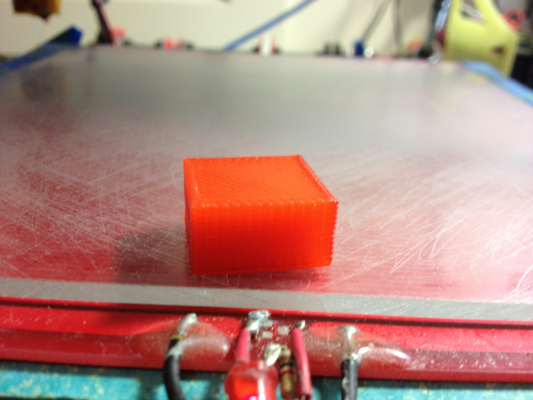

From a lot of calibration cube tests I have found that an extrusion multiplier of .74 is the maximum I can have in order to get zero swarf/jumping. I am able to print well but essentially solid infill is really only 74% infill and layer width is not correct:

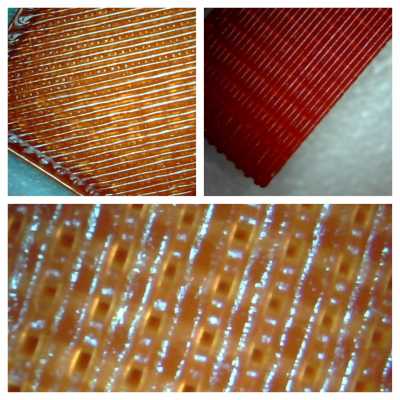

Edit:Clockwise from top left, top of cube (incorrect layer width),side of cube (no bumps), top of cube (close up).

Click here if you don't see a 3 pic image above

I suspect my extrusion is not controlled enough to stop the excess extrusion where there is rapid reduction in hotend speed at the perimeter edges.

Any thoughts on this matter are appreciated.

Any thing someone can suggest i will test.

I have been able to reduce the effect by increasing accelleration from 1000 to 3000 however my drivers/motors can't achieve this and loose a step occasionally.

Edited 2 time(s). Last edit at 07/23/2013 08:17AM by Gibbedy.

In order to solve this problem I am going to calibrate again in the hope that someone will be able to help me with this.

I am attempting to calibrate a prusa i1 with jhead MKIV-B hotend, 3mm, PLA.

Measure 50mm of filament with vernier from top of extruder:

Extrude 50mm in pronterface and expect to see mark flush with the top of the extruder:

At this point I am happy that my e-steps are correct.

Next I slic3 up a .5mm thin wall at .4 layer height:

I measure .57mm wall width (top couple of layers). Gcode says it should be .53mm.

I reduce e multiplier from 1 to .92 in slic3r and print again to get correct .53mm measurement

Next I print a 20mm cube:

This measures 19.6 x 19.7 at the centers. (I'm not sure if this is an issue?)

This print looks good however infill produces bumps at the perimeter edges. This is a problem where the hotend has to do a travel move over this infill. On a larger print it is constantly making a noise where the hotend jumps over these bumps and can lead to jams.

Edit:Clockwise from top left, top of cube (correct layer width),side of cube (see bumps that cause problems), top of cube (close up).

Click here if you don't see a 3 pic image above

From a lot of calibration cube tests I have found that an extrusion multiplier of .74 is the maximum I can have in order to get zero swarf/jumping. I am able to print well but essentially solid infill is really only 74% infill and layer width is not correct:

Edit:Clockwise from top left, top of cube (incorrect layer width),side of cube (no bumps), top of cube (close up).

Click here if you don't see a 3 pic image above

I suspect my extrusion is not controlled enough to stop the excess extrusion where there is rapid reduction in hotend speed at the perimeter edges.

Any thoughts on this matter are appreciated.

Any thing someone can suggest i will test.

I have been able to reduce the effect by increasing accelleration from 1000 to 3000 however my drivers/motors can't achieve this and loose a step occasionally.

Edited 2 time(s). Last edit at 07/23/2013 08:17AM by Gibbedy.

|

Re: Getting over extrusion at perimeter edges July 24, 2013 04:22PM |

Registered: 11 years ago Posts: 342 |

From what I've read adjusting that multiplier is just a bandage to a deeper problem. Something is off in your firmware, slicer, extruder, hotend, or filament. I would start with the filament diameter. I have found it varies over the length of a spool and I measure it and adjust this value in my slicer before every slice and print. If the slicer thinks it's going to get so many cubic mm of filament by extruding 5 mm of filament and it actually get's a greater or lesser volume while printing, that will mess up your print.

|

Re: Getting over extrusion at perimeter edges July 24, 2013 04:45PM |

Registered: 12 years ago Posts: 156 |

appdev007 Wrote:

-------------------------------------------------------

> From what I've read adjusting that multiplier is

> just a bandage to a deeper problem.

Or it might just be that he's extruding too fast, getting more die swell than the norm.

In which case adjusting the multiplier is a perfectly legitimate tweak.

-------------------------------------------------------

> From what I've read adjusting that multiplier is

> just a bandage to a deeper problem.

Or it might just be that he's extruding too fast, getting more die swell than the norm.

In which case adjusting the multiplier is a perfectly legitimate tweak.

|

Re: Getting over extrusion at perimeter edges July 24, 2013 05:02PM |

Registered: 11 years ago Posts: 342 |

orcinus Wrote:

-----------------------------------------------

> Or it might just be that he's extruding too fast,

> getting more die swell than the norm.

> In which case adjusting the multiplier is a

> perfectly legitimate tweak.

OK, I'm game. Why wouldn't lowering your E steps in firmware be the correct way to fix this?

-----------------------------------------------

> Or it might just be that he's extruding too fast,

> getting more die swell than the norm.

> In which case adjusting the multiplier is a

> perfectly legitimate tweak.

OK, I'm game. Why wouldn't lowering your E steps in firmware be the correct way to fix this?

|

Re: Getting over extrusion at perimeter edges July 24, 2013 08:10PM |

Registered: 12 years ago Posts: 156 |

|

Re: Getting over extrusion at perimeter edges July 25, 2013 02:02AM |

Registered: 11 years ago Posts: 342 |

|

Re: Getting over extrusion at perimeter edges July 25, 2013 09:38PM |

Registered: 11 years ago Posts: 560 |

|

Re: Getting over extrusion at perimeter edges July 26, 2013 03:36AM |

Registered: 11 years ago Posts: 1,592 |

|

Re: Getting over extrusion at perimeter edges July 26, 2013 11:13PM |

Registered: 11 years ago Posts: 342 |

I'm sorry, your pics wouldn't load the first time I read your post and I don't like clicking on links for domains I don't know well.

What hot end and bed temp are you using for PLA?

If it's above 180, I would be curious to see how your prints came out if you did three more. Lower your hot end temp by one degree, print, check that one, and repeat two more times lowering one degree each time. Let the part cool all the way before checking it.

What hot end and bed temp are you using for PLA?

If it's above 180, I would be curious to see how your prints came out if you did three more. Lower your hot end temp by one degree, print, check that one, and repeat two more times lowering one degree each time. Let the part cool all the way before checking it.

|

Re: Getting over extrusion at perimeter edges July 30, 2013 01:43PM |

Registered: 10 years ago Posts: 5 |

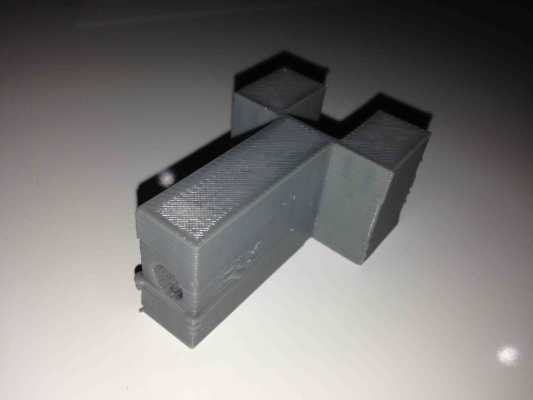

is this the same problem ? All my print will have some non smooth edge at some point during the print. I really don't know what caused it. It was printed with PLA at 185 degree, with layer height 0.3.

Steps X,Y,Z,E are as follow (50.7, 50.7, 2560, 800)

It usually happens when it is printing a section of a layer that has small print area.

if you look at the picture, the layer at which ooze happen was while printing small area at the side of the hole.

would really appreciate your help/advice. thanks.

|

Re: Getting over extrusion at perimeter edges August 31, 2013 09:09AM |

Registered: 12 years ago Posts: 86 |

Hello again.

Thankyou everyone.

I have read all the posts and has given me things to think about for future problems.

I was speaking to reifsnyderb on irc about my issue and he suggested that it may be too high extrusion pressure on my MKIV-B jhead.

He sen't me a replacement MKV-B jhead and it has solved this issue.

problem sorted.

Thankyou everyone.

I have read all the posts and has given me things to think about for future problems.

I was speaking to reifsnyderb on irc about my issue and he suggested that it may be too high extrusion pressure on my MKIV-B jhead.

He sen't me a replacement MKV-B jhead and it has solved this issue.

problem sorted.

|

Re: Getting over extrusion at perimeter edges September 22, 2013 01:00AM |

Registered: 11 years ago Posts: 45 |

I'm actually having the same issue; have been since I've built my MendelMax 1.5. It happens with ABS and PLA. Since it takes less pressure to push ABS through, I'm hoping it is just a firmware setting issue. I'll try keeping modyfing the Emax mm/s to acceleration ratio to match my XY ratio, as suggested above. The ratio is currently not even close.

EDIT: Unfortunately it didn't work. I have DEFAULT_MAX_FEEDRATE set to 150 mm/s for X and Y, and 25mm/s for E, and DEFAULT_MAX_ACCELERATION set to 500 mm/s^2 for X, Y, and 83.33 mm/s^2 for E. Maybe 500 mm/s^2 is too slow of an acceleartion and that is causing issues? I had it set to 1500 mm/2^2 but reduced it thinking it might help increase print quality.

Edited 1 time(s). Last edit at 09/22/2013 01:15AM by Zangetsu57.

EDIT: Unfortunately it didn't work. I have DEFAULT_MAX_FEEDRATE set to 150 mm/s for X and Y, and 25mm/s for E, and DEFAULT_MAX_ACCELERATION set to 500 mm/s^2 for X, Y, and 83.33 mm/s^2 for E. Maybe 500 mm/s^2 is too slow of an acceleartion and that is causing issues? I had it set to 1500 mm/2^2 but reduced it thinking it might help increase print quality.

Edited 1 time(s). Last edit at 09/22/2013 01:15AM by Zangetsu57.

|

Re: Getting over extrusion at perimeter edges September 22, 2013 03:38AM |

Registered: 13 years ago Posts: 1,797 |

ok so we accurately measure the feedstock, but that is not all we measure. we need to know exact nozzle size. my guess is your nozzle is slightly off. experiment by decreasing it, and increasing it. also look at your retraction settings. possibly too much or to little retraction is used. what hot end are you using? then in the end, are you quite sure those calipers are correct? without new batteries and proper tension to the measurement bar measurement can be off. slide the bar back to zero. does your caliper read zero again?

if all else then likely the diameter of feedstock is set to default of 2.85 to 3.00mm measure your overall diameter of feedstock. measure at every 90deg for 4 measurements then divide this by 4. this will give you the most accurate measure of feedstock. enter this number into slicer settings. diameter varies from roll to roll. make sure to use correct settings.

Also how fast is perimeters being laid down? too slow and your nozzle can ooze, too fast and depending on your hardware setup it may not shape corners correctly. outlines are good around 15mm/s to 30mm/s infill can be much faster because no one looks at the inside of a printed part, and it usually is a water tight model anyways.

in summary:

accurately measure and calibrate using length of feedstock and enter diameter of feedstock as well.

adjust nozzle size up and down in software +/- 0.05mm and somewhere in between likely.

look at perimeter and determine feed rate. between 15-30mm for outside perimeter is a safe bet.

finally if all else recalculate flow rate in slicer program and then when done compensate for accuracy in firmware.

Then be prepared to comment and add what you've learned. I've been surprised by several instances where something simple that has not happened to anyone before seems to be the culprit, such as a zip tie in the way of the nozzle, feedstock quality issues, temp being too high. for example. surprise us all!

others may chime in with more. best of luck!

if all else then likely the diameter of feedstock is set to default of 2.85 to 3.00mm measure your overall diameter of feedstock. measure at every 90deg for 4 measurements then divide this by 4. this will give you the most accurate measure of feedstock. enter this number into slicer settings. diameter varies from roll to roll. make sure to use correct settings.

Also how fast is perimeters being laid down? too slow and your nozzle can ooze, too fast and depending on your hardware setup it may not shape corners correctly. outlines are good around 15mm/s to 30mm/s infill can be much faster because no one looks at the inside of a printed part, and it usually is a water tight model anyways.

in summary:

accurately measure and calibrate using length of feedstock and enter diameter of feedstock as well.

adjust nozzle size up and down in software +/- 0.05mm and somewhere in between likely.

look at perimeter and determine feed rate. between 15-30mm for outside perimeter is a safe bet.

finally if all else recalculate flow rate in slicer program and then when done compensate for accuracy in firmware.

Then be prepared to comment and add what you've learned. I've been surprised by several instances where something simple that has not happened to anyone before seems to be the culprit, such as a zip tie in the way of the nozzle, feedstock quality issues, temp being too high. for example. surprise us all!

others may chime in with more. best of luck!

Sorry, only registered users may post in this forum.