Extruder hot end oozing problem

Posted by Karl_Williams

|

Extruder hot end oozing problem March 20, 2012 01:38PM |

Registered: 12 years ago Posts: 53 |

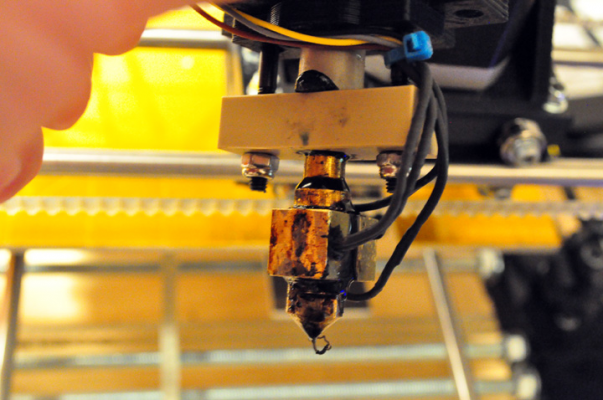

My extruder hot end started oozing last week. This is the one that came with my botmill glider so I'm not sure what version it is. I took it apart, cleaned all the plastic out and then reassembled it. I thought that the problem might have been caused by doing 3mm retracts while printing. I'm using black PLA at a temperature of 205 degrees. Last night I couldn't get through a small test print without the problem happening again. I'm pretty sure that the plastic is escaping from the point where the brass piece fits into that plastic piece (see photo 3). I'm running marlin firmware on a Gen6 Deluxe board from mendel-parts. Before this happened I was getting some nice prints. Now that I have it taken apart again, my questions are:

1) Should I be using some sort of thread lock or teflon tape for where the nozzle and that brass tube thread into the heater block?

2) Is there some sort of high temperature glue that I should use to attach the brass tube to the plastic piece (photo 3)? I notice that the two are held together with 2 hex bolts and nuts and another plastic piece. I was afraid of making those too tight in case it bent that piece but now I'm wondering if that wasn't tight enough?

3) Should I just order a new hot end from someone else? Which one would you recommend?

Any help would be appreciated, Karl

1) Should I be using some sort of thread lock or teflon tape for where the nozzle and that brass tube thread into the heater block?

2) Is there some sort of high temperature glue that I should use to attach the brass tube to the plastic piece (photo 3)? I notice that the two are held together with 2 hex bolts and nuts and another plastic piece. I was afraid of making those too tight in case it bent that piece but now I'm wondering if that wasn't tight enough?

3) Should I just order a new hot end from someone else? Which one would you recommend?

Any help would be appreciated, Karl

|

Re: Extruder hot end oozing problem March 20, 2012 01:52PM |

Registered: 12 years ago Posts: 77 |

|

Re: Extruder hot end oozing problem March 20, 2012 02:14PM |

Registered: 15 years ago Posts: 123 |

|

Re: Extruder hot end oozing problem March 20, 2012 07:20PM |

Registered: 14 years ago Posts: 689 |

That looks like the mendel-parts v6 hotend? It's notorious for leaking in my experience. To stop it you need to add generous amount of plumbers tape, as well as the copper washers that should come with the set, and tighten it very hard.

I also cut the ptfe tube/liner a few mm too long to compressed it and make a better seal.

You also have the peek block the wrong way around btw, and it might not hold up very long like that.

The hotend itself is pretty decent though, and you can get very nice prints with it. It does suffer from the huge melt chamber though, it does drool quite a bit, gunk will build up inside it and clog the nozzle, and you might have to print at higher temperatures than with other hotends.

I have a small write-ups on my blog with some more information that could be of value: [repraprip.blogspot.com]

--

-Nudel

Blog with RepRap Comic

I also cut the ptfe tube/liner a few mm too long to compressed it and make a better seal.

You also have the peek block the wrong way around btw, and it might not hold up very long like that.

The hotend itself is pretty decent though, and you can get very nice prints with it. It does suffer from the huge melt chamber though, it does drool quite a bit, gunk will build up inside it and clog the nozzle, and you might have to print at higher temperatures than with other hotends.

I have a small write-ups on my blog with some more information that could be of value: [repraprip.blogspot.com]

--

-Nudel

Blog with RepRap Comic

|

Re: Extruder hot end oozing problem March 21, 2012 01:12AM |

Registered: 14 years ago Posts: 800 |

|

Re: Extruder hot end oozing problem March 21, 2012 07:20PM |

Registered: 12 years ago Posts: 53 |

|

Re: Extruder hot end oozing problem March 25, 2012 08:37PM |

Registered: 12 years ago Posts: 53 |

I put the hot end back together and used ptfe tape on the threads for the nozzle and the brass tube and put the peek block on the right way around. I almost got through printing the whistle when plastic started oozing out where the peek tube attaches to the brass tube, and then jammed up the wades. The threaded parts with the ptfe tape didn`t leak this time.

Do you think I can stop the oozing by attaching the peek tube and the brass piece with JB weld?

I notice that inside the peek tube there is a nylon lining tube that the filament goes through. It goes about 2mm inside the brass tube. Should it go further down? Is this the piece that others have mentioned gluing inside the brass tube? What kind of glue would I use? Crazy glue (cyanoacrylate) or would JB weld work? It`s a really tight fit.

I printed through a 1 kilogram spool of pla before these problems started last week. I`ve ordered a couple of different replacement hot ends that I`ve heard good things about just in case I can`t get this one to work:

http://www.makergear.com/products/operators-pack

http://reprap-fab.org/shop/product_info.php?products_id=80

Do you think I can stop the oozing by attaching the peek tube and the brass piece with JB weld?

I notice that inside the peek tube there is a nylon lining tube that the filament goes through. It goes about 2mm inside the brass tube. Should it go further down? Is this the piece that others have mentioned gluing inside the brass tube? What kind of glue would I use? Crazy glue (cyanoacrylate) or would JB weld work? It`s a really tight fit.

I printed through a 1 kilogram spool of pla before these problems started last week. I`ve ordered a couple of different replacement hot ends that I`ve heard good things about just in case I can`t get this one to work:

http://www.makergear.com/products/operators-pack

http://reprap-fab.org/shop/product_info.php?products_id=80

|

Re: Extruder hot end oozing problem April 07, 2012 02:09PM |

Registered: 12 years ago Posts: 20 |

Have you seen the assembly instructions at [www.mendel-parts.com] ? The PTFE lining tube should be 37mm, so it should go 7mm into the brass part. As you've already mentioned, some people even need to glue the PTFE lining to the brass part to stop leaking. Also, I've heard that it is very important to really *crush* the brass/copper parts when attaching the heater block to the tube and the nozzle.

I've very curious about your experiences with the other hot ends you've ordered. Please keep us up to date :-).

--------

Visit my blog: [blog.agten.net]

I've very curious about your experiences with the other hot ends you've ordered. Please keep us up to date :-).

--------

Visit my blog: [blog.agten.net]

|

Re: Extruder hot end oozing problem April 09, 2012 10:34AM |

Registered: 12 years ago Posts: 53 |

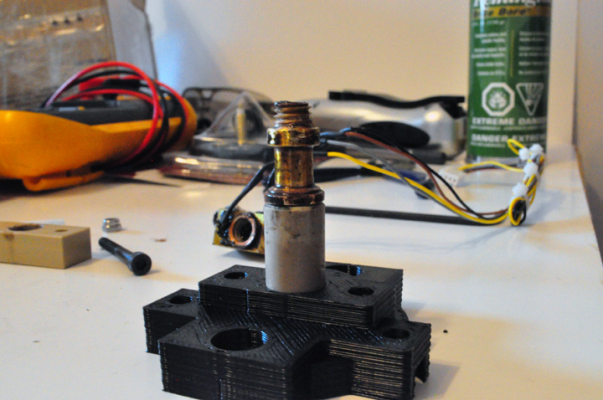

Thanks for the link to the assembly instructions. The ptfe tube in my hotend is only 26.57 mm long - 10.5 mm shorter than it should be. So that explains why it eventually failed. It looks like it may have shrunk a bit and deformed on the end from the heat. I was getting very nice prints from that hotend until it failed. So I probably just need to get some new ptfe tube and cut it to the proper length?

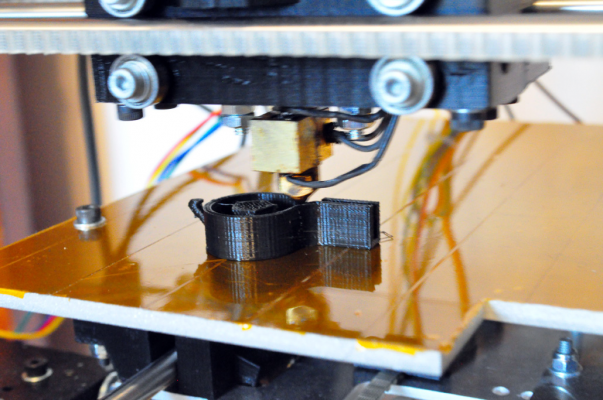

The MakerGear hotend arrived in less than a week and I installed it a couple of days ago. It heats up quickly and I don't have to run it as hot as I did with the v6. It has different characteristics than the v6. I've been tweaking the skeinforge settings and almost have it printing as nice as the v6. I still need to figure out the retraction settings because after doing a retraction it leaves a blob when it puts the filament back to where it started. I'm thinking that maybe the retraction should be smaller and not as fast, maybe slow the acceleration for the extruder in the firmware, or maybe lower the temperature a few degrees? Seems like a nice hotend so far.

I haven't received the reprap-fab hotend yet but I noticed on their website that it won't be expected in stock until April 18. I'm not sure if mine shipped when I ordered it or it I have to wait but it has to travel from Germany to Canada. I'll let you know how that one works out too.

ptfe tube

Makergear hotend 1

Makergear hotend 2

Gen6 wired

The MakerGear hotend arrived in less than a week and I installed it a couple of days ago. It heats up quickly and I don't have to run it as hot as I did with the v6. It has different characteristics than the v6. I've been tweaking the skeinforge settings and almost have it printing as nice as the v6. I still need to figure out the retraction settings because after doing a retraction it leaves a blob when it puts the filament back to where it started. I'm thinking that maybe the retraction should be smaller and not as fast, maybe slow the acceleration for the extruder in the firmware, or maybe lower the temperature a few degrees? Seems like a nice hotend so far.

I haven't received the reprap-fab hotend yet but I noticed on their website that it won't be expected in stock until April 18. I'm not sure if mine shipped when I ordered it or it I have to wait but it has to travel from Germany to Canada. I'll let you know how that one works out too.

ptfe tube

Makergear hotend 1

Makergear hotend 2

Gen6 wired

|

Re: Extruder hot end oozing problem May 01, 2012 11:41AM |

Registered: 12 years ago Posts: 53 |

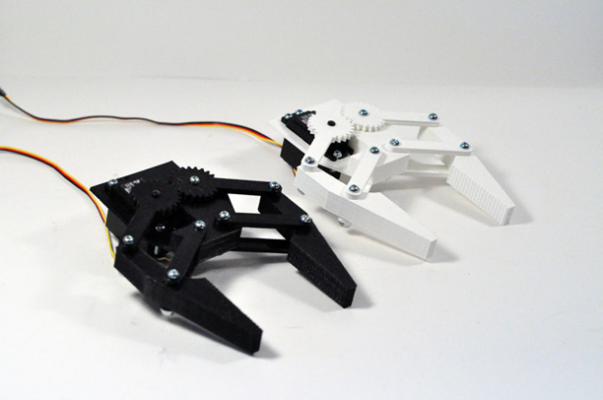

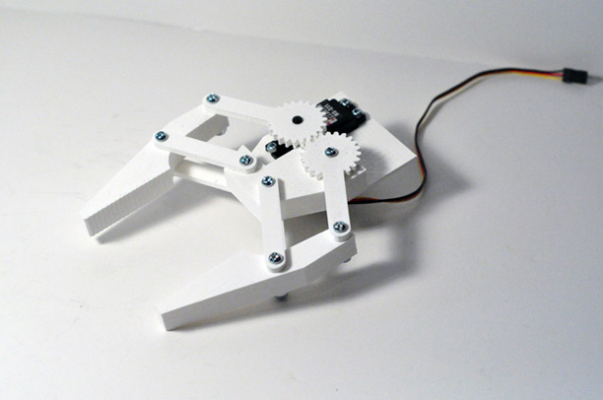

I finally had some time to tune the MakerGear hotend and I'm getting nice consistent prints now. I had to add a bigger cooling fan to keep the filament feed end of the hotend cool. I'm using a wades extruder on what I think is the original Mendel X carriage and there isn't a lot of room for air flow so the bigger fan was necessary. The blobbing I was seeing during retraction is gone now that I have the proper settings for retraction speed and filament distance. Also, I purchased some good PLA from Ultimachine and it seems to be of better quality than the stuff that came from China. I still haven't received the hotend from reprap fab yet. Here are some photos of a robot gripper I designed in solidworks and printed with the MakerGear hotend:

Edited 1 time(s). Last edit at 05/01/2012 12:28PM by Karl_Williams.

Edited 1 time(s). Last edit at 05/01/2012 12:28PM by Karl_Williams.

|

Re: Extruder hot end oozing problem November 15, 2013 12:18PM |

Registered: 11 years ago Posts: 10 |

Sorry, only registered users may post in this forum.