$40, 1000w, 12x12" heated build plate

Posted by LoboCNC

|

$40, 1000w, 12x12" heated build plate August 07, 2014 08:29PM |

Registered: 11 years ago Posts: 564 |

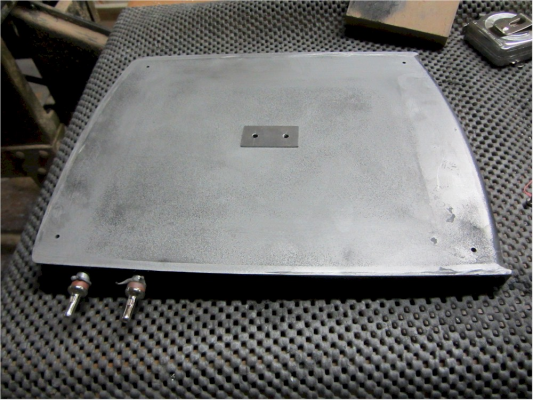

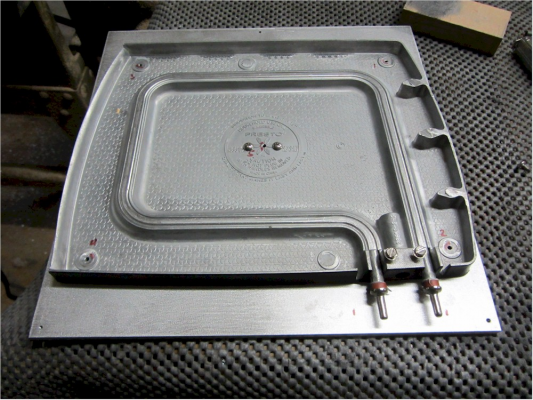

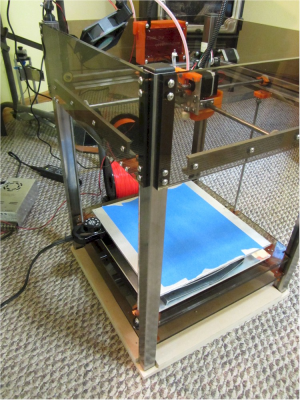

I needed a 12"x12" heated build plate for my new printer, but given the size (and thus, power required), it seemed to make much more sense using an AC powered heater. Wanting to avoid dealing with high-voltage, I decided to try using an electric griddle. Specifically, a Presto Liddle Griddle (~$25). I was tempted to try just parking the thing right out of the box on my printer bed, but after a little testing with my feeble IR thermometer, I realized that the temp across the griddle surface varied too much (~15C) and that the hysteresis was too high (also ~15C). It was also a little too small. My final version (ok, current version) uses a 1/4" aluminum plate screwed to the center of the griddle surface by separated by a small 0.040" thick aluminum plate. I then mounted the 1/4" plate on 3 stainless steel screw standoffs to a 1/4" plywood base to thermally insulate it from the acrylic Z platform it rests on. I also put a piece of mirrored mylar on top of the plywood as a radiant heat barrier. So far, I've just tested it with printing PLA and setting it to about 50C (just below the "Warm" setting on the dial). It goes all the way up to about 200C, so I really need to put a hard-stop on the dial to keep from inadvertently setting it above 100C. There was a bit of trial and error in the construction to avoid warpage as the plate heated up, but so far it seems to work OK - a temp variation across the surface of about 4C and hysteresis of about 2-3C. Jury's still out as to whether I'd recommend this or not.

...after cutting away the bits I didn't need

...after cutting away the bits I didn't need

|

Re: $40, 1000w, 12x12" heated build plate August 07, 2014 09:06PM |

Registered: 11 years ago Posts: 1,049 |

I think the controller uses a simple bi-metal sensor / controller?

You NOT using feedback, A thermistor on the bed.

Use a Bang - Bang controller -- controlled by your main controller board

switching triacs or relays to handle the high voltage / current.

You could also PWM the temperature controller.

For a real Rube Goldberg --- drive a servo off of the main control board

to twist the control dial????

Why do you need such a big heater?

---- Need to heat up in 12 milliseconds?

---- Need to keep 27 pounds of material at temperature

---- Why do you need your bed at 200 C same as extruder?

Oh CNC pancakes --- OK!!

What is so wrong with a $20 12 x 12" 12V silicone heater

--- 12''x12'' 12v Silicone Rubber Heater Bed For 3d Printer

---- Price: US $20.00 / piece

----- [www.aliexpress.com]

----- [store.quintessentialuniversalbuildingdevice.com]

Edited 2 time(s). Last edit at 08/07/2014 09:22PM by cozmicray.

You NOT using feedback, A thermistor on the bed.

Use a Bang - Bang controller -- controlled by your main controller board

switching triacs or relays to handle the high voltage / current.

You could also PWM the temperature controller.

For a real Rube Goldberg --- drive a servo off of the main control board

to twist the control dial????

Why do you need such a big heater?

---- Need to heat up in 12 milliseconds?

---- Need to keep 27 pounds of material at temperature

---- Why do you need your bed at 200 C same as extruder?

Oh CNC pancakes --- OK!!

What is so wrong with a $20 12 x 12" 12V silicone heater

--- 12''x12'' 12v Silicone Rubber Heater Bed For 3d Printer

---- Price: US $20.00 / piece

----- [www.aliexpress.com]

----- [store.quintessentialuniversalbuildingdevice.com]

Edited 2 time(s). Last edit at 08/07/2014 09:22PM by cozmicray.

|

Re: $40, 1000w, 12x12" heated build plate August 07, 2014 09:29PM |

Registered: 11 years ago Posts: 564 |

Cozmicray: The answer to pretty much all your questions is $25. I don't really need 1000w or 200C and thermistor sensing with PID control would be preferable, but a simple bang-bang controller with a bi-metal sensor/controller is what you get on a $25 griddle. And with a bit of fussing, it works OK. In the past, I've rolled my own AC powered nichchome wire heated bed and controller, but working with 120v always makes me a little queasy. I just wanted to see if I could mod an off-the-shelf AC heater.

Mmmm, pancakes!

Mmmm, pancakes!

|

Re: $40, 1000w, 12x12" heated build plate August 07, 2014 10:00PM |

Registered: 11 years ago Posts: 564 |

And as for Rube Goldberg - a bi-metal strip is an incredibly simple and reliable mechanism for temperature control. A few pieces of stamped metal that must cost them all of 50 cents to make, all integrated into the (somewhat large) power connector. The more "standard" solution - thermistor, power MOSFET, 400w power supply, lots of wiring and connectors, a 16MHz microcontroller executing who knows how many lines of code - now that seems a little far-fetched...

Edited 2 time(s). Last edit at 08/07/2014 10:25PM by LoboCNC.

Edited 2 time(s). Last edit at 08/07/2014 10:25PM by LoboCNC.

|

Re: $40, 1000w, 12x12" heated build plate August 08, 2014 06:25PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: $40, 1000w, 12x12" heated build plate August 08, 2014 06:56PM |

Registered: 11 years ago Posts: 564 |

Quote

cozmicray

What controller are you using for your printer?

It probably has bed heater control built in?

Just use it?

I'm using a Printrboard which does have heated bed control built-in, but I'm guessing I'd need about a 400w heater for the 12x12" bed, and I doubt it'll handle the required current. I could have it switch a solid-state relay and use AC power, but like I said, I'm hoping to not horse around with AC. (Especially since I've got some high school students building their own printers based on my design.) I could switch to a beefier controller and use 24v, but I'd still need a 400w power supply. Like I alluded to earlier, it seems like there are all sorts or relatively cheap, high power, pre-engineered heating solutions in the world and I was curious if one could be easily modified for a heated bed. The mod'ed griddle does work, but it did take a little effort. The main drawback is that It doesn't shut off automatically when the print is done, although I might just plug it into a timer switch. Not terribly automated, but again, it'll work for my needs. (Definitely what you'd call a hack.)

|

Re: $40, 1000w, 12x12" heated build plate August 09, 2014 01:01PM |

Registered: 11 years ago Posts: 1,049 |

Sorry, only registered users may post in this forum.