Firmware Choice & Setup Issues. Help & Ill be your friend

Posted by KealanOCarroll

|

Firmware Choice & Setup Issues. Help & Ill be your friend December 05, 2014 03:27AM |

Registered: 9 years ago Posts: 13 |

Hi Lads & Ladies,

Greetings from Ireland!

I've built myself a delta from bits of wooden planks from the garage, mucho cable ties, and a SainSmart RAMPS 1.4 kit from eBay.

I've been using Repetier Host & FW; mainly because I can't get prontface to install on my laptop

I tried Marlin, which threw me loads of compiling errors, then finally uploaded, but Repetier host wouldn't communicate with it properly for some reason, so I've just stuck with repetier FW for now. I don't really like the repetier config.h: I'd prefer the marlin style one where there's instructions commented in...I prefer changing the config settings manually in IDE rather than building a config from the repetier config tool online.

Is Repetier Host a solid stable host to use, same for Repetier FW ? I'd like to start off with the most reliable host & fw to start because I have a all the config & calibration to do.

Ok, so the problems I'm having so far:

M119 gives me X,Y, and Z High, and each of them low if I hit the switch, which seems right for an NC endstop. The problem is when I hit the endstop the stepper doesn't stop moving, in either direction.

I plugged in the 3 jumpers under each A4988 driver, but the steppers are moving at a snails pace now. I tried setting the max speed and acceleration int he FW up to about 4k mm/min, and everything from 80 to 800 steps/mm, but the stepper is still only crawling around. Removing the jumpers makes the stepper move at a mroe realistic speed, but it's doing full steps only (I think) so it's incredibly loud and vibratory. The only reference I could see to this in the repetier FW is an enable Z babystepping, which I have on...am I missing a firmware setting?

Amm...next up; only the Y axis moves when I jog either X or Y directions in the host. The ramps is on top of the printer, in the middle, and the wires to the steppers and endstops are going out either direction, so i dont think there's any interference going on. Earlier on, both X and Y were moving with a Y jog, but jogging X didn't do anything. I haven't played with the trim pots (yet), but the NEMA 17 steppers are outputting a hefty torque whilst getting warm but not worryingly hot, so I think they're okay.

I plugged in the clone Mk5 hotend lastnight (Getting a genuine Mk5 BV for christmas) and I got a beautiful critically damped type response from the thermistor reading up to about 180*C, so that's one thing that seems to be working okay.

I'm using a 360 PS, controlled by the board. M80 and 81 are working that okay.

I have the endstops connected as MAX stops, and the MINS disabled...The homing direction is upwards too so that seems grand, but activating the end stop doesn't stop the stepper moving, which is worrying.

Can anyone shed any light, or point me in the direction of a decent explanation of the setup? I'm okay-ish with the hardware but software definitely isn't my forté, so I'm in a little over my head trying to debug the software, but hey; you never learn anything in your comfort zone

Any help at all would be greatly appreciated, I'm willing to try anything to help get my head around all of this and get a proper understanding of it all

Greetings from Ireland!

I've built myself a delta from bits of wooden planks from the garage, mucho cable ties, and a SainSmart RAMPS 1.4 kit from eBay.

I've been using Repetier Host & FW; mainly because I can't get prontface to install on my laptop

I tried Marlin, which threw me loads of compiling errors, then finally uploaded, but Repetier host wouldn't communicate with it properly for some reason, so I've just stuck with repetier FW for now. I don't really like the repetier config.h: I'd prefer the marlin style one where there's instructions commented in...I prefer changing the config settings manually in IDE rather than building a config from the repetier config tool online.

Is Repetier Host a solid stable host to use, same for Repetier FW ? I'd like to start off with the most reliable host & fw to start because I have a all the config & calibration to do.

Ok, so the problems I'm having so far:

M119 gives me X,Y, and Z High, and each of them low if I hit the switch, which seems right for an NC endstop. The problem is when I hit the endstop the stepper doesn't stop moving, in either direction.

I plugged in the 3 jumpers under each A4988 driver, but the steppers are moving at a snails pace now. I tried setting the max speed and acceleration int he FW up to about 4k mm/min, and everything from 80 to 800 steps/mm, but the stepper is still only crawling around. Removing the jumpers makes the stepper move at a mroe realistic speed, but it's doing full steps only (I think) so it's incredibly loud and vibratory. The only reference I could see to this in the repetier FW is an enable Z babystepping, which I have on...am I missing a firmware setting?

Amm...next up; only the Y axis moves when I jog either X or Y directions in the host. The ramps is on top of the printer, in the middle, and the wires to the steppers and endstops are going out either direction, so i dont think there's any interference going on. Earlier on, both X and Y were moving with a Y jog, but jogging X didn't do anything. I haven't played with the trim pots (yet), but the NEMA 17 steppers are outputting a hefty torque whilst getting warm but not worryingly hot, so I think they're okay.

I plugged in the clone Mk5 hotend lastnight (Getting a genuine Mk5 BV for christmas) and I got a beautiful critically damped type response from the thermistor reading up to about 180*C, so that's one thing that seems to be working okay.

I'm using a 360 PS, controlled by the board. M80 and 81 are working that okay.

I have the endstops connected as MAX stops, and the MINS disabled...The homing direction is upwards too so that seems grand, but activating the end stop doesn't stop the stepper moving, which is worrying.

Can anyone shed any light, or point me in the direction of a decent explanation of the setup? I'm okay-ish with the hardware but software definitely isn't my forté, so I'm in a little over my head trying to debug the software, but hey; you never learn anything in your comfort zone

Any help at all would be greatly appreciated, I'm willing to try anything to help get my head around all of this and get a proper understanding of it all

|

Re: Firmware Choice & Setup Issues. Help & Ill be your friend December 05, 2014 04:14AM |

Registered: 10 years ago Posts: 580 |

Kealan,

I'm just going to take a stab at a couple of the issues.

Repetier is good stuff. I'd say stick with it. I use a display with a SD card (using a Rumba controller) so I'm not printing from the host myself. I do agree about the comments, would be better there! I think there is a way you can download the full firmware and get a commented configuration.h for reference.

Note that once you get the basic settings done and firmware flashed, then you can use Repetier Host to change the e-prom settings and not have to re-flash again.

Do you have the following for your endstops? You may need to play with the true/false.

#define ENDSTOP_X_MAX_INVERTING true

Now about the microstepping jumpers - you will probably want to use 16 microsteps, since that is quieter and more accurate.

You will need to set the steps per mm to match. See Triffid_Hunter's_Calibration_Guide

Make sure the steppers are wired in the right order, and in the right polarity. There should be a wiring guide here somewhere. DO NOT change any wiring with the controller powered, you can blow a driver that way.

If you have the printer oriented so there is a tower on the left, one on the right, and one directly at the back, then the one on the left is the "A" or "X" tower, the one on the right is the "B" or "Y" tower, and the one at the back is the "C" or "Z" tower. Some people use A,B,C for the towers so as to not confuse them with cardinal directions. Make sure the motors are wired that way.

Check the stepper directions:

Do a manual command in Repetier Host to move the effector down, say g0 x0 y0 z50

This should move all cars on the towers down. You can change the direction using the invert settings in the configuration.h like this:

#define INVERT_X_DIR 1

#define INVERT_Y_DIR 0

#define INVERT_Z_DIR 1

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

When you get to calibrating your extruder, I found this guide helpful.

Note that many people use Slic3r, and a lot of the calibration guides do too, so that may be easier to follow along with if you also use it.

Cheers

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

I'm just going to take a stab at a couple of the issues.

Repetier is good stuff. I'd say stick with it. I use a display with a SD card (using a Rumba controller) so I'm not printing from the host myself. I do agree about the comments, would be better there! I think there is a way you can download the full firmware and get a commented configuration.h for reference.

Note that once you get the basic settings done and firmware flashed, then you can use Repetier Host to change the e-prom settings and not have to re-flash again.

Do you have the following for your endstops? You may need to play with the true/false.

#define ENDSTOP_X_MAX_INVERTING true

Now about the microstepping jumpers - you will probably want to use 16 microsteps, since that is quieter and more accurate.

You will need to set the steps per mm to match. See Triffid_Hunter's_Calibration_Guide

Make sure the steppers are wired in the right order, and in the right polarity. There should be a wiring guide here somewhere. DO NOT change any wiring with the controller powered, you can blow a driver that way.

If you have the printer oriented so there is a tower on the left, one on the right, and one directly at the back, then the one on the left is the "A" or "X" tower, the one on the right is the "B" or "Y" tower, and the one at the back is the "C" or "Z" tower. Some people use A,B,C for the towers so as to not confuse them with cardinal directions. Make sure the motors are wired that way.

Check the stepper directions:

Do a manual command in Repetier Host to move the effector down, say g0 x0 y0 z50

This should move all cars on the towers down. You can change the direction using the invert settings in the configuration.h like this:

#define INVERT_X_DIR 1

#define INVERT_Y_DIR 0

#define INVERT_Z_DIR 1

#define X_HOME_DIR -1

#define Y_HOME_DIR -1

#define Z_HOME_DIR -1

When you get to calibrating your extruder, I found this guide helpful.

Note that many people use Slic3r, and a lot of the calibration guides do too, so that may be easier to follow along with if you also use it.

Cheers

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Firmware Choice & Setup Issues. Help & Ill be your friend December 05, 2014 05:22AM |

Registered: 9 years ago Posts: 13 |

Thanks Paul

Unfortunately I'm stuck at work at the moment so I have to wait till this evening.

Good to know the repetier is a solid base to work from anyway! I have an LCD display & SD Reader too, which works okay but it's a bit clumsy for the testing I'm doing at the moment; I think it's probably easier to debug from the PC with the nicer interface and the "monitoring window" as it were giving the commands sent and such.

I'll definitely use the G0 to test the steppers rather than the jogger buttons!

I took a multimeter to the steppers, and got 2 coils in each (continuity between one pair of wires an an open circuit between the two pairs?) Then wired one coil to 1A1B and the other coil to 2A2B. From what i gather the polarity of the pairs doesn't matter, as long as the pairs are indeed paired correctly?

I'm assuming my steppers are 1.8 deg, so 200 setps/rev and thus 80 steps/mm with 1/16th stepping on a GT2 belt on a 20T pulley.

If they're 0.9* steppers, surely it's 160 steps/mm, twice the steps if each step is half the angle? I put in 80/mm, 200/mm, and 800/mm, none of which got the steppers to move at any form of normal speed though, so I'm not sure if the steps/mm setting is what's causing the stepper problem

I'll have a look for the full repetier commented FW I don't actually have an extruder yet...or a hobbed gear, or any filament...or any way of mounting the hot end

I don't actually have an extruder yet...or a hobbed gear, or any filament...or any way of mounting the hot end  There's no panic on the setup that way though; I can take my time getting the motion working properly before I go getting excited and trying to rush out my first print!

There's no panic on the setup that way though; I can take my time getting the motion working properly before I go getting excited and trying to rush out my first print!

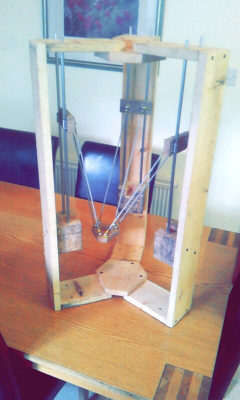

This is her before I got the electronics:

Edited 1 time(s). Last edit at 12/08/2014 10:54AM by DeuxVis.

Unfortunately I'm stuck at work at the moment so I have to wait till this evening.

Good to know the repetier is a solid base to work from anyway! I have an LCD display & SD Reader too, which works okay but it's a bit clumsy for the testing I'm doing at the moment; I think it's probably easier to debug from the PC with the nicer interface and the "monitoring window" as it were giving the commands sent and such.

I'll definitely use the G0 to test the steppers rather than the jogger buttons!

I took a multimeter to the steppers, and got 2 coils in each (continuity between one pair of wires an an open circuit between the two pairs?) Then wired one coil to 1A1B and the other coil to 2A2B. From what i gather the polarity of the pairs doesn't matter, as long as the pairs are indeed paired correctly?

I'm assuming my steppers are 1.8 deg, so 200 setps/rev and thus 80 steps/mm with 1/16th stepping on a GT2 belt on a 20T pulley.

If they're 0.9* steppers, surely it's 160 steps/mm, twice the steps if each step is half the angle? I put in 80/mm, 200/mm, and 800/mm, none of which got the steppers to move at any form of normal speed though, so I'm not sure if the steps/mm setting is what's causing the stepper problem

I'll have a look for the full repetier commented FW

I don't actually have an extruder yet...or a hobbed gear, or any filament...or any way of mounting the hot end

I don't actually have an extruder yet...or a hobbed gear, or any filament...or any way of mounting the hot end  There's no panic on the setup that way though; I can take my time getting the motion working properly before I go getting excited and trying to rush out my first print!

There's no panic on the setup that way though; I can take my time getting the motion working properly before I go getting excited and trying to rush out my first print! This is her before I got the electronics:

Edited 1 time(s). Last edit at 12/08/2014 10:54AM by DeuxVis.

|

Re: Firmware Choice & Setup Issues. Help & Ill be your friend December 05, 2014 02:00PM |

Registered: 10 years ago Posts: 580 |

When you do a g0 x0 y0 z50 it is using the default feed rate you have set in firmware. You can override this like so:

g0 x0 y0 z50 f100

This would use 100mm/sec for the feed rate. That would be a conservative move speed.

You can measure how far the effector moves strait down and that will give you an idea if you are about correct with your steps per mm.

You are going to need to look at the accelerations.

I have attached a configuration.h from my printer which has some fairly conservative accelerations (since it's a larger sized printer). The extruder has higher accelerations perhaps than usual (using Nema 23 motors).

Cheers

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

g0 x0 y0 z50 f100

This would use 100mm/sec for the feed rate. That would be a conservative move speed.

You are correct. You can reverse the rotation by switching the pairs from 1A1B to 2A2B, or in firmware as above.Quote

I took a multimeter to the steppers, and got 2 coils in each (continuity between one pair of wires an an open circuit between the two pairs?) Then wired one coil to 1A1B and the other coil to 2A2B. From what i gather the polarity of the pairs doesn't matter, as long as the pairs are indeed paired correctly?

You can measure how far the effector moves strait down and that will give you an idea if you are about correct with your steps per mm.

You are going to need to look at the accelerations.

I have attached a configuration.h from my printer which has some fairly conservative accelerations (since it's a larger sized printer). The extruder has higher accelerations perhaps than usual (using Nema 23 motors).

Cheers

My printer: Raptosaur - Large Format Delta - [www.paulwanamaker.wordpress.com]

Can you answer questions about Calibration, Printing issues, Mechanics? Write it up and improve the Wiki!

|

Re: Firmware Choice & Setup Issues. Help & Ill be your friend December 05, 2014 06:03PM |

Registered: 9 years ago Posts: 13 |

Update:

Got sick of repetier not working, so I downloaded a fresh copy or marlin and found an exe installer for prontface so I'm using that combo now

I removed the microstepping jumpers, then removed the stepper drivers and set up the axis direction and end stops for each axis with only their respective drivers plugged in...then plugged all the drivers in afterwards and it seems to be working better now. At the moment when I hit home it'll drive all the carriages upwards till they hit their end stops, then one by one it'll move them back down a little and slowly step them up to their end stops again. I'm presuming this is a "coarse tune" and then "fine tune" setting in marlin.

I adjusted the trim pots to about 0.75 amps per stepper, but they're getting too hot to touch if left on for more than a few seconds so I reckon I'll back them off more. I'm finding it near impossible to get a voltage reading between either side of the trim pots and gnd though: does the stepper have to have current going to it to read that voltage or does the board just need to be powered up??

With the microstepping jumpers removed the firmware is set at 0.005 steps/mm. That's giving me about 5mm of actual travel for a 10mm gcode command, but I'd like to use the 1/16th for smoothness (& better resolution?) So it'll take some messing about to set it up. I've had some weird results with upping the speed & acceleration making the carriages move further and slower... so I'm a little confused!

It seems to take the prontface hose ages to talk to the board; it feels like there's a 30s delay in everything?! After homing the steppers tend to stay locked too; and it won't acknowledge a reset or power off or any other serial communication unless I do a hard reset on the board:-/

Need to get my LCD/SD set up too.

Having major fun; there's some kick out of watching it move as I want it to

Got sick of repetier not working, so I downloaded a fresh copy or marlin and found an exe installer for prontface so I'm using that combo now

I removed the microstepping jumpers, then removed the stepper drivers and set up the axis direction and end stops for each axis with only their respective drivers plugged in...then plugged all the drivers in afterwards and it seems to be working better now. At the moment when I hit home it'll drive all the carriages upwards till they hit their end stops, then one by one it'll move them back down a little and slowly step them up to their end stops again. I'm presuming this is a "coarse tune" and then "fine tune" setting in marlin.

I adjusted the trim pots to about 0.75 amps per stepper, but they're getting too hot to touch if left on for more than a few seconds so I reckon I'll back them off more. I'm finding it near impossible to get a voltage reading between either side of the trim pots and gnd though: does the stepper have to have current going to it to read that voltage or does the board just need to be powered up??

With the microstepping jumpers removed the firmware is set at 0.005 steps/mm. That's giving me about 5mm of actual travel for a 10mm gcode command, but I'd like to use the 1/16th for smoothness (& better resolution?) So it'll take some messing about to set it up. I've had some weird results with upping the speed & acceleration making the carriages move further and slower... so I'm a little confused!

It seems to take the prontface hose ages to talk to the board; it feels like there's a 30s delay in everything?! After homing the steppers tend to stay locked too; and it won't acknowledge a reset or power off or any other serial communication unless I do a hard reset on the board:-/

Need to get my LCD/SD set up too.

Having major fun; there's some kick out of watching it move as I want it to

Sorry, only registered users may post in this forum.