Large format printer sliders

Posted by L4nce0

|

Large format printer sliders June 13, 2015 06:25AM |

Registered: 13 years ago Posts: 68 |

Hi everyone.

I'm building a printer that is in the 600-800mm XY print length (each not combined)

I'm having issues finding a supplier for these linear rails / slides. I got the Z axis off ebay from PBC linear. I am trying to stay in PBC linear quality. However the guys at info@aapautomation.com don't seem that interested in returning my emails. Which is who PBC told me to email.. So I'm on my own I guess.

I'm looking at

[www.newmarksystems.com]

This looks perfect, Too good to be true! Wait! Maybe it is! Seems it takes a NEMA 23 And they wont show me a price (really bad sign!!!) I'm not looking to spend more than 1k for the XY motion. Preferably less, but high quality and speed matters most. If I'm pressed hard, my budget would be like 1300 with shipping..

I haven't picked out electronics yet, but it sounds like from reading other posts that they are difficult to get to work with logic boards. Mostly that the stepper voltage regulators will get too hot and their bigger counterparts have a different pin out. I'm trying to do this as painless and with as little custom work as possible. I have a lot on my plate with this project as it stands!

The rest are a bunch of junk chinese mono rails on ebay clogging my google search results.

Anyone have experience with these? I mean outside of buying a gigabot haha (even with 700 dollar linear actuators, this printer is going to come in at a third of their 10k price!)

Edited 2 time(s). Last edit at 06/13/2015 06:29AM by L4nce0.

I'm building a printer that is in the 600-800mm XY print length (each not combined)

I'm having issues finding a supplier for these linear rails / slides. I got the Z axis off ebay from PBC linear. I am trying to stay in PBC linear quality. However the guys at info@aapautomation.com don't seem that interested in returning my emails. Which is who PBC told me to email.. So I'm on my own I guess.

I'm looking at

[www.newmarksystems.com]

This looks perfect, Too good to be true! Wait! Maybe it is! Seems it takes a NEMA 23 And they wont show me a price (really bad sign!!!) I'm not looking to spend more than 1k for the XY motion. Preferably less, but high quality and speed matters most. If I'm pressed hard, my budget would be like 1300 with shipping..

I haven't picked out electronics yet, but it sounds like from reading other posts that they are difficult to get to work with logic boards. Mostly that the stepper voltage regulators will get too hot and their bigger counterparts have a different pin out. I'm trying to do this as painless and with as little custom work as possible. I have a lot on my plate with this project as it stands!

The rest are a bunch of junk chinese mono rails on ebay clogging my google search results.

Anyone have experience with these? I mean outside of buying a gigabot haha (even with 700 dollar linear actuators, this printer is going to come in at a third of their 10k price!)

Edited 2 time(s). Last edit at 06/13/2015 06:29AM by L4nce0.

|

Re: Large format printer sliders June 13, 2015 07:38AM |

Registered: 11 years ago Posts: 5,781 |

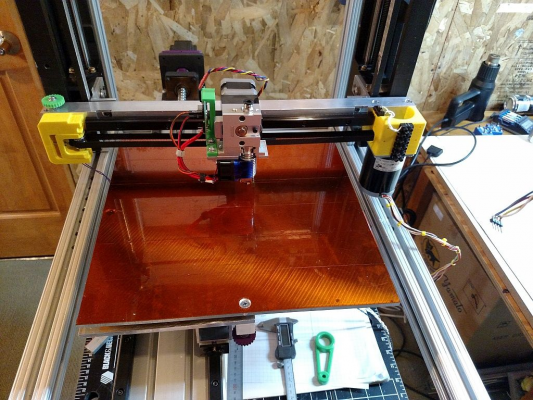

That looks a lot like the X axis I built for my machine-

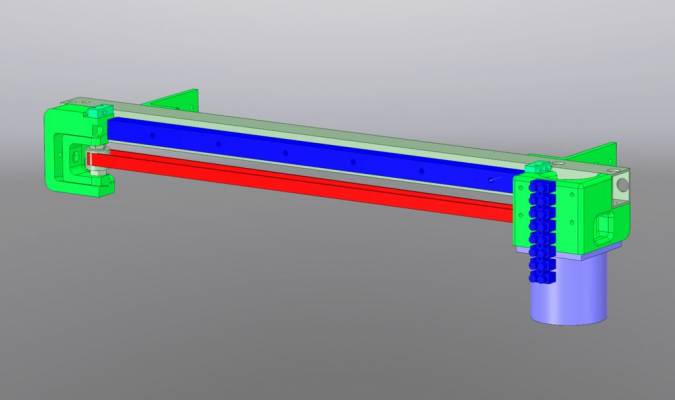

It uses a linear guide screwed to a 1" square aluminum tube with printed NEMA-23 motor mount and belt tensioner. It isn't really very difficult or expensive to make in any length you need, and the linear guide will perform better than wheels riding on an aluminum extrusion. You can pick up used linear guides with matching bearing blocks on ebay for $50-100.

I use this to drive it: driver with a 32V power supply, and use an identical set-up in the Y axis. The stepper drivers plug directly into a Smoothieboard controller, so there's minimal screwing around.

You can see the whole machine here: http://www.instructables.com/id/An-Almost-Reliable-High-Precision-3D-Printer-Son-o/

Edited 1 time(s). Last edit at 06/13/2015 07:39AM by the_digital_dentist.

It uses a linear guide screwed to a 1" square aluminum tube with printed NEMA-23 motor mount and belt tensioner. It isn't really very difficult or expensive to make in any length you need, and the linear guide will perform better than wheels riding on an aluminum extrusion. You can pick up used linear guides with matching bearing blocks on ebay for $50-100.

I use this to drive it: driver with a 32V power supply, and use an identical set-up in the Y axis. The stepper drivers plug directly into a Smoothieboard controller, so there's minimal screwing around.

You can see the whole machine here: http://www.instructables.com/id/An-Almost-Reliable-High-Precision-3D-Printer-Son-o/

Edited 1 time(s). Last edit at 06/13/2015 07:39AM by the_digital_dentist.

|

Re: Large format printer sliders June 19, 2015 11:17AM |

Registered: 13 years ago Posts: 68 |

Yes that looks a lot like what I need. I called up the clowns at newmark systems they wanted something like 8k for 4 1000mm smooth rods, two nema 23 steppers, two belts, two carriages and some mounts.

Though whats with the "almost" reliable part? I rather spend 2k and get always reliable, as a mistake can ruin a 2 day print.

Edited 1 time(s). Last edit at 06/19/2015 11:17AM by L4nce0.

Though whats with the "almost" reliable part? I rather spend 2k and get always reliable, as a mistake can ruin a 2 day print.

Edited 1 time(s). Last edit at 06/19/2015 11:17AM by L4nce0.

|

Re: Large format printer sliders June 19, 2015 11:29AM |

Registered: 11 years ago Posts: 5,781 |

"Almost" as in 3D printing is not a 100% reliable process in general. I spent a couple years working out as many of the machine related reliability problems as I could, but failures still occur. One of the bigger causes of failure is still bed adhesion. Not that ABS won't stick to the bed, but that it is variable and depends on the footprint of the part being printed. If I select the wrong bed adhesion method or orient the part on the bed poorly, or try to print 20 small parts at once, a few will come loose and screw up most of the rest of them. Call it an operator error, or some other type of error, but it still happens and prints still fail. I've also had failures where the filament gets tangled on the spool. I haven't figured out a remedy for that yet. Then there are slicer software issues. Sometimes the software screws up and leaves you with a bad print.

You can't get "always reliable" no matter how much you spend.

You can't get "always reliable" no matter how much you spend.

|

Re: Large format printer sliders June 19, 2015 01:10PM |

Registered: 11 years ago Posts: 335 |

Linear rail bolted to tslot is really your best option.

Getting the right used rail at a reasonable price can be a PITA so it might be worth just going to Hwin or another Chinese supplier and having them set you up with new parts. Even supported linear shaft is pretty accurate and disgustingly cheap as well.

Getting the right used rail at a reasonable price can be a PITA so it might be worth just going to Hwin or another Chinese supplier and having them set you up with new parts. Even supported linear shaft is pretty accurate and disgustingly cheap as well.

|

Re: Large format printer sliders June 21, 2015 07:59PM |

Registered: 13 years ago Posts: 68 |

Quote

691175002

Linear rail bolted to tslot is really your best option.

Getting the right used rail at a reasonable price can be a PITA so it might be worth just going to Hwin or another Chinese supplier and having them set you up with new parts. Even supported linear shaft is pretty accurate and disgustingly cheap as well.

Thats pretty close to what I went with.

[openbuildspartstore.com]

I contacted PBC linear sales person. Took several emails to get the the sales person. He kept asking for hard core mech engineering specs and requirements.. which kinda defeats the purpose of getting help via a sales person. After almost 2 weeks (only a few days with the sales person) I had enough time to do more research.

I came across these folks and something interesting called open rails.

[openbuildspartstore.com]

I saw them about a week ago and dismissed them thinking I probably couldn't get the rigidness and quality I wanted. Though thinking about it, I realized I probably could if I used a double extruded aluminum as the base. Also the 3 rails at 1000 mm + came out to about 500 with everything like motors, idelers, nema 17 mounts. That includes the all metal wheels (going with 6 for the main axis, 4 on the others). The wheels are the most pricy part. I really liked that I could later change my mind on the length and no problem. Worst case I replace the extruded aluminum and maybe replace a edge segment (like 3 bucks).

I didn't find max speeds, but I don't see why I couldn't get 150mms/s on them. I might have to go up on stepper motor size, but I like that it ill be no big deal if I do (spare the part where I'll have 60 in motors to replace. Looks pretty easy to combine the x to the y axis too!

It was cool that they had a whole gallery of other peoples large projects. The large ones were mostly slow CNC but they has small Reprap like printers.

Edited 1 time(s). Last edit at 06/21/2015 08:01PM by L4nce0.

Sorry, only registered users may post in this forum.