This the right place to ask about suggestions?

Posted by MegaRocketPenguin

|

This the right place to ask about suggestions? July 16, 2015 04:03PM |

Registered: 8 years ago Posts: 75 |

Kind of new to this forum, semi new to 3d printing.

I intern at a company every summer that has a Makerbot Rep 2 and a Form 1+. I have grown to hate the makerbot so much, I want to buy/build a 3d printer of my own. The makerbot almost never works, and I was always given the duty of making it work. Most of the time I succeeded, other times I failed. Anyway, point being, I know stuff about printers. Mostly the operation and troubleshooting. And taking apart and rebuilding hotends and extruders. Anyway, moving on.

So, as I said, I am looking to either buy or build a 3d printer. Now my budget isn't the biggest. I would like to spend 350$ or less on the printer (In the beginning, upgrades come later.) I was doing some research, and it would look as if the Prusa i3 would be the best DIY printer to build for such given price range. Me being my lazy self and enjoying the ability to rely on others, I have been looking at kits. (Yea, I know, bad idea.) Fitting my budget, I have found this: [www.aliexpress.com] The main reason I chose this, other than price, is because it has no 3d printed parts. Yes, I know, reprap's main goal is to be able to self replicate. I however, find 3d printed parts a little, how do you say, unprofessional? Yes, I realize it does lower cost, however, my biggest fear is that one of these parts could break. I have also heard a lot of horror stories of purchased printed parts coming warped/incorrect size/require finishing work to be able to be used. One of my few issues with this kit is that it uses acrylic, which I have heard tends to crack. I do, however, see that there are aluminum upgrade kits. But I was thinking to myself, if I am going to upgrade more than half the kit, why not just build my own from various sources? The only issue I have found, is that there is no way around 3d printed parts. This kit proved the parts usually 3d printed as part of their acrylic frame. I have not been able to find any aluminum kit able to do this. Is there any way around 3d printed parts? Is that kit any good? Any better kits? Any precompiled BOM for a prusa i3 under 350-400$ without printed parts?

Another question.

I really like the design of the Makerbot Replicator 2/2x/most of their newer ones. Specifically, I like designs that have the build plate only move on the Z axis. Why aren't there many DIY 3d printers that move the hotend on the x and y axis, while the bed only moves on the z? To me, it doesn't seem that hard to do. Are there any good kits that work as such for my price range? Looking at the BOM for a prusa i3, and the parts of a makerbot, it would seem as if it would be quite easy to make a makerbot clone using nothing but prusa parts. The only difference needed is a frame. All the eletronics, bearings, slide rails, hotend, etc would work, right?

Anyway, any recommendations for a 3d printer in the 350-40$ (400 would be the maximum.)? Preferably kit, but would also do a BOM so long as it has all the parts listed. Preferably no printed parts. Would like something like the makerbot, where the hotend moves on x and y, and the build plate on the Z.

Any other recommendations for a first time printer buyer would also be nice.

I intern at a company every summer that has a Makerbot Rep 2 and a Form 1+. I have grown to hate the makerbot so much, I want to buy/build a 3d printer of my own. The makerbot almost never works, and I was always given the duty of making it work. Most of the time I succeeded, other times I failed. Anyway, point being, I know stuff about printers. Mostly the operation and troubleshooting. And taking apart and rebuilding hotends and extruders. Anyway, moving on.

So, as I said, I am looking to either buy or build a 3d printer. Now my budget isn't the biggest. I would like to spend 350$ or less on the printer (In the beginning, upgrades come later.) I was doing some research, and it would look as if the Prusa i3 would be the best DIY printer to build for such given price range. Me being my lazy self and enjoying the ability to rely on others, I have been looking at kits. (Yea, I know, bad idea.) Fitting my budget, I have found this: [www.aliexpress.com] The main reason I chose this, other than price, is because it has no 3d printed parts. Yes, I know, reprap's main goal is to be able to self replicate. I however, find 3d printed parts a little, how do you say, unprofessional? Yes, I realize it does lower cost, however, my biggest fear is that one of these parts could break. I have also heard a lot of horror stories of purchased printed parts coming warped/incorrect size/require finishing work to be able to be used. One of my few issues with this kit is that it uses acrylic, which I have heard tends to crack. I do, however, see that there are aluminum upgrade kits. But I was thinking to myself, if I am going to upgrade more than half the kit, why not just build my own from various sources? The only issue I have found, is that there is no way around 3d printed parts. This kit proved the parts usually 3d printed as part of their acrylic frame. I have not been able to find any aluminum kit able to do this. Is there any way around 3d printed parts? Is that kit any good? Any better kits? Any precompiled BOM for a prusa i3 under 350-400$ without printed parts?

Another question.

I really like the design of the Makerbot Replicator 2/2x/most of their newer ones. Specifically, I like designs that have the build plate only move on the Z axis. Why aren't there many DIY 3d printers that move the hotend on the x and y axis, while the bed only moves on the z? To me, it doesn't seem that hard to do. Are there any good kits that work as such for my price range? Looking at the BOM for a prusa i3, and the parts of a makerbot, it would seem as if it would be quite easy to make a makerbot clone using nothing but prusa parts. The only difference needed is a frame. All the eletronics, bearings, slide rails, hotend, etc would work, right?

Anyway, any recommendations for a 3d printer in the 350-40$ (400 would be the maximum.)? Preferably kit, but would also do a BOM so long as it has all the parts listed. Preferably no printed parts. Would like something like the makerbot, where the hotend moves on x and y, and the build plate on the Z.

Any other recommendations for a first time printer buyer would also be nice.

|

Re: This the right place to ask about suggestions? July 16, 2015 06:52PM |

Registered: 9 years ago Posts: 1,873 |

Moving the bed in Z is difficult to do well and cheaply (nothing new there then), but it appeals to me too. If I was starting over I would probably try and build a smartrap core. It doesn't exactly meet your requirements - it has printed parts and the kit comes over budget, but I like the approach. On the Prusa i3 front, the P3Steel gets a lot of positive comments.

|

Re: This the right place to ask about suggestions? July 16, 2015 07:44PM |

Registered: 8 years ago Posts: 3 |

Hi,new posting in this forum but a intense reader last months. I'm from Spain and have some dificults in english,sorry. Since i was afraid to make a 3d printer from zero i buy one of this all acrilics from Alibaba. Crap,s...t. o wathever you want say. PURE TRASH. Since i only pay 219 $ plus 42$ shiping cost I'I'm happy with the amount of parts i can salvage to make a steel one.

|

Re: This the right place to ask about suggestions? July 16, 2015 08:05PM |

Registered: 8 years ago Posts: 75 |

Quote

JamesK

Moving the bed in Z is difficult to do well and cheaply (nothing new there then), but it appeals to me too. If I was starting over I would probably try and build a smartrap core. It doesn't exactly meet your requirements - it has printed parts and the kit comes over budget, but I like the approach. On the Prusa i3 front, the P3Steel gets a lot of positive comments.

Ooh, I really like the look of the smartrap core... That’s pretty much what I would like. Looking at it, it looks like I might make one of those, but not as my first printer. I dislike printed parts, but aren't completely against them, especially if I print them myself.

Forgot about the P3Steel. Would definitely want to get that. It appears it may be a little steep for my budget, but might as well fit it in. I do not want a printer that doesn't function at all. May as well build my own from scratch then. I found one on Ebay, but I am not sure if it is any good. Is there any official website/trusted sellers?

Know of any good places to buy steppers and other printer parts? Any guide pages on quality parts I should purchase? Any personal recommendations?

And what I might do, is simply make a Prusa, get it going, print my own parts, and either build a second printer, or use parts from the prusa to create a SmartRap Core...

Edit: Was looking at the P3Steel frame, and I noticed it does in fact, require printed parts. More specifically, the parts on either end of the X axis (Hotend is attached to it) that hold the X axis rods and Z axis bearings. Now, I can budge a little bit on printed parts (Though the first thing I would print is another set or two of them...) so it shouldn't be too much of an issue (Would be better if I could find a solution to this other than buying printed parts...) Any good source on buying printed parts for decent prices? Slowly making up a theoretical BOM.

Edited 2 time(s). Last edit at 07/16/2015 08:18PM by MegaRocketPenguin.

|

Re: This the right place to ask about suggestions? July 16, 2015 08:08PM |

Registered: 8 years ago Posts: 75 |

Quote

garabitu

Hi,new posting in this forum but a intense reader last months. I'm from Spain and have some dificults in english,sorry. Since i was afraid to make a 3d printer from zero i buy one of this all acrilics from Alibaba. Crap,s...t. o wathever you want say. PURE TRASH. Since i only pay 219 $ plus 42$ shiping cost I'I'm happy with the amount of parts i can salvage to make a steel one.

Thanks for the input. I too, am a bit afraid of making a printer from parts I would buy myself, and thus am also looking at a kit. Could you go into detail as of why it wasn't up to your expectations? The acrylic start breaking? Was there anything good in it? What broke first/what was the issue with it?

Thanks again for input!

|

Re: This the right place to ask about suggestions? July 16, 2015 08:20PM |

Registered: 9 years ago Posts: 1,873 |

I've been buying all my parts through AliExpress. Obviously it's going to vary with the particular seller you deal with, but I've been very pleased with the parts and service from this vendor that I bought the electronics and print head from:

[www.aliexpress.com]

It did take a long time for stuff to arrive - up to a couple of months in some cases, but it all got here in the end. After I bought the print head they started including a spare nozzle and heat break, and they even agreed to send me those parts in a later order.

I'm still a long way from finishing the printer so I can't vouch for how well some of the parts work (particularly the print head/extruder), but I've had no problems testing out the controller/lcd/motors/endstops on the X & Y axes.

[www.aliexpress.com]

It did take a long time for stuff to arrive - up to a couple of months in some cases, but it all got here in the end. After I bought the print head they started including a spare nozzle and heat break, and they even agreed to send me those parts in a later order.

I'm still a long way from finishing the printer so I can't vouch for how well some of the parts work (particularly the print head/extruder), but I've had no problems testing out the controller/lcd/motors/endstops on the X & Y axes.

|

Re: This the right place to ask about suggestions? July 16, 2015 08:25PM |

Registered: 11 years ago Posts: 5,780 |

|

Re: This the right place to ask about suggestions? July 16, 2015 09:02PM |

Registered: 8 years ago Posts: 75 |

Quote

the_digital_dentist

If I may suggest, before you buy into a $300-400 kit, have a look at this to learn a little about what you're giving up to get to that price point. If nothing else it may help you develop a more critical eye toward evaluating different kits before you send someone your hard-earned cash.

I read the Important bits, and I learned a lot of what I didn't know/needed clearing up on. Would love a low maintenance 3d printer, but my budget doesn't cover anything near as fancy as that beast you linked. It did have a lot on quality parts though, and what to look out for.

Thanks for the info!

|

Re: This the right place to ask about suggestions? July 17, 2015 05:15AM |

Registered: 8 years ago Posts: 3 |

A friend and I buy two of them to make expenses and customs cheaper.

First thing was some little pieces not sending, curiosly not the same in both printers. Since they are things like screws, plastic pillars, a pair of end stops and a bearing we took them from ours scrap box.

Second., nothing about a manual only a pdf not very hepfull. Third issue the all acrilic frame, really a fragile thing. You need to be very caute when screw the parts toghether they tend to break very easy.

Other issue and most important the laser cut is not scuared. There are a slighty angle in the cut along the stiffnes of the acrilic, this supousse you are incapable to get rigt angles within the parts. The adition of this little errors go to the vertical rods and z screw to be inacurate positioned to the point that you cant move the z sttepers in any way. In the vertical frame those innacuracys make a slighty curve puting tension on the x carriage.

Now we are triying to get rigth angles in all the acrilic parts and save the wole thing but here i Spain you can get a 3mm steel frame about 40$ that we think is coming to be the solution.

A I say in the other post in this cheaper price we get good steppers, inox rood, trapezoidal screws, brass nuts, linear bearings ..... aceptable quality.

Ok a long post in a crappy english. Sorry guy.

First thing was some little pieces not sending, curiosly not the same in both printers. Since they are things like screws, plastic pillars, a pair of end stops and a bearing we took them from ours scrap box.

Second., nothing about a manual only a pdf not very hepfull. Third issue the all acrilic frame, really a fragile thing. You need to be very caute when screw the parts toghether they tend to break very easy.

Other issue and most important the laser cut is not scuared. There are a slighty angle in the cut along the stiffnes of the acrilic, this supousse you are incapable to get rigt angles within the parts. The adition of this little errors go to the vertical rods and z screw to be inacurate positioned to the point that you cant move the z sttepers in any way. In the vertical frame those innacuracys make a slighty curve puting tension on the x carriage.

Now we are triying to get rigth angles in all the acrilic parts and save the wole thing but here i Spain you can get a 3mm steel frame about 40$ that we think is coming to be the solution.

A I say in the other post in this cheaper price we get good steppers, inox rood, trapezoidal screws, brass nuts, linear bearings ..... aceptable quality.

Ok a long post in a crappy english. Sorry guy.

|

Re: This the right place to ask about suggestions? July 17, 2015 11:58AM |

Registered: 8 years ago Posts: 75 |

Quote

garabitu

A friend and I buy two of them to make expenses and customs cheaper.

First thing was some little pieces not sending, curiosly not the same in both printers. Since they are things like screws, plastic pillars, a pair of end stops and a bearing we took them from ours scrap box.

Second., nothing about a manual only a pdf not very hepfull. Third issue the all acrilic frame, really a fragile thing. You need to be very caute when screw the parts toghether they tend to break very easy.

Other issue and most important the laser cut is not scuared. There are a slighty angle in the cut along the stiffnes of the acrilic, this supousse you are incapable to get rigt angles within the parts. The adition of this little errors go to the vertical rods and z screw to be inacurate positioned to the point that you cant move the z sttepers in any way. In the vertical frame those innacuracys make a slighty curve puting tension on the x carriage.

Now we are triying to get rigth angles in all the acrilic parts and save the wole thing but here i Spain you can get a 3mm steel frame about 40$ that we think is coming to be the solution.

A I say in the other post in this cheaper price we get good steppers, inox rood, trapezoidal screws, brass nuts, linear bearings ..... aceptable quality.

Ok a long post in a crappy english. Sorry guy.

Oh wow. That sounds really bad. Yea, I'll probably just stick to sourcing the parts myself then... Didn't realize they were that bad.

It's alright, thanks for the info!

|

Re: This the right place to ask about suggestions? July 18, 2015 03:36PM |

Registered: 9 years ago Posts: 705 |

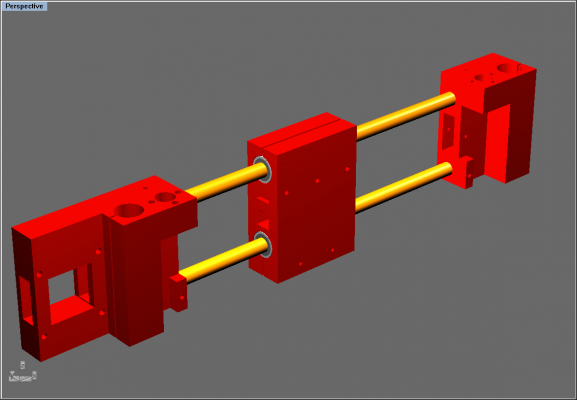

My kits x motor mount and idler mount were printed terribly also. I redesigned them with set screws for mounting the x rods. Much easier assembly. They use (4) bearings instead of (2). If you want the STL files for them let me know. Brian.Quote

garabitu

A friend and I buy two of them to make expenses and customs cheaper.

First thing was some little pieces not sending, curiosly not the same in both printers. Since they are things like screws, plastic pillars, a pair of end stops and a bearing we took them from ours scrap box.

Second., nothing about a manual only a pdf not very hepfull. Third issue the all acrilic frame, really a fragile thing. You need to be very caute when screw the parts toghether they tend to break very easy.

Other issue and most important the laser cut is not scuared. There are a slighty angle in the cut along the stiffnes of the acrilic, this supousse you are incapable to get rigt angles within the parts. The adition of this little errors go to the vertical rods and z screw to be inacurate positioned to the point that you cant move the z sttepers in any way. In the vertical frame those innacuracys make a slighty curve puting tension on the x carriage.

Now we are triying to get rigth angles in all the acrilic parts and save the wole thing but here i Spain you can get a 3mm steel frame about 40$ that we think is coming to be the solution.

A I say in the other post in this cheaper price we get good steppers, inox rood, trapezoidal screws, brass nuts, linear bearings ..... aceptable quality.

Ok a long post in a crappy english. Sorry guy.

|

Re: This the right place to ask about suggestions? July 18, 2015 03:38PM |

Registered: 8 years ago Posts: 75 |

Quote

elwood127

My kits x motor mount and idler mount were printed terribly also. I redesigned them with set screws for mounting the x rods. Much easier assembly. They use (4) bearings instead of (2). If you want the STL files for them let me know. Brian.Quote

garabitu

A friend and I buy two of them to make expenses and customs cheaper.

First thing was some little pieces not sending, curiosly not the same in both printers. Since they are things like screws, plastic pillars, a pair of end stops and a bearing we took them from ours scrap box.

Second., nothing about a manual only a pdf not very hepfull. Third issue the all acrilic frame, really a fragile thing. You need to be very caute when screw the parts toghether they tend to break very easy.

Other issue and most important the laser cut is not scuared. There are a slighty angle in the cut along the stiffnes of the acrilic, this supousse you are incapable to get rigt angles within the parts. The adition of this little errors go to the vertical rods and z screw to be inacurate positioned to the point that you cant move the z sttepers in any way. In the vertical frame those innacuracys make a slighty curve puting tension on the x carriage.

Now we are triying to get rigth angles in all the acrilic parts and save the wole thing but here i Spain you can get a 3mm steel frame about 40$ that we think is coming to be the solution.

A I say in the other post in this cheaper price we get good steppers, inox rood, trapezoidal screws, brass nuts, linear bearings ..... aceptable quality.

Ok a long post in a crappy english. Sorry guy.

[attachment 58354 XCarraigeAssembly.jpg]

This for the Folger 2020 i3 printer?

Sorry, only registered users may post in this forum.