Help deciding on a build

Posted by aussie_g

|

Help deciding on a build November 01, 2015 11:22PM |

Registered: 8 years ago Posts: 1 |

Ok, I have decided to build a printer, and am about to order a Makerfarm i3 kit.

But after a lot of research, im starting to wonder if I should piece a kit together myself so that I can get the parts I want without having to upgrade the kit.

So far, these are the features I think I want.

Ramps 1.4

E3d-v6 hot end

8" kit

Aluminum bed plate

I intend to install a self levelling using an inductive prox that I already have.

Im not so sure how I feel about the greg's extruder that comes with the kit.

Any of you guys with experience, can you give me any ideas on the extruder & hotend choices.

Im really looking to have a hot/cold end setup that will offer good performance with good reliability.

Thanks in advance guys, this is my first post but I plan on being here a lot....

But after a lot of research, im starting to wonder if I should piece a kit together myself so that I can get the parts I want without having to upgrade the kit.

So far, these are the features I think I want.

Ramps 1.4

E3d-v6 hot end

8" kit

Aluminum bed plate

I intend to install a self levelling using an inductive prox that I already have.

Im not so sure how I feel about the greg's extruder that comes with the kit.

Any of you guys with experience, can you give me any ideas on the extruder & hotend choices.

Im really looking to have a hot/cold end setup that will offer good performance with good reliability.

Thanks in advance guys, this is my first post but I plan on being here a lot....

|

Re: Help deciding on a build November 01, 2015 11:39PM |

Registered: 9 years ago Posts: 182 |

I went the self source route when I built my printer and ended up working out for the most part OK. By not buying a kit you lose the ability of good customer service that is accompanied with more expensive non-ebay kits. From someone who had no experience with 3d printers using or building them, service can be a valuable thing.

From my build standpoint here are a couple of things I would make sure to get for the printer.

-Proper leads crews

-Rigid frame

-High Quality E3d V6 or Equivalent hotend

-Electronics not from eBay (learned this the hardway)

-proper sized motors

Also I have found my Wades extruder to be flawless. No issues with filament being stripped and tons of torque with my 76oz in steppers and a 5ish to 1 gear ratio.

Edited 1 time(s). Last edit at 11/01/2015 11:40PM by gmckee.

Prusa i3 Rework - Ramps 1.4 - E3d Lite6 - Full Graphic LCD Controller

From my build standpoint here are a couple of things I would make sure to get for the printer.

-Proper leads crews

-Rigid frame

-High Quality E3d V6 or Equivalent hotend

-Electronics not from eBay (learned this the hardway)

-proper sized motors

Also I have found my Wades extruder to be flawless. No issues with filament being stripped and tons of torque with my 76oz in steppers and a 5ish to 1 gear ratio.

Edited 1 time(s). Last edit at 11/01/2015 11:40PM by gmckee.

Prusa i3 Rework - Ramps 1.4 - E3d Lite6 - Full Graphic LCD Controller

|

Re: Help deciding on a build November 02, 2015 07:40AM |

Registered: 11 years ago Posts: 5,781 |

I have been using a BullDog XL extruder and E3D v6 hot end in my printer since last December without a single jam or other problem of any kind (printing ABS).

One of the big problems with buying a kit is that they typically have poor frame construction. That severely limits what you can do to improve the machine.

If you decide to DIY, by all means start with a rigid frame, but also think in terms of eliminating anything else that's flexible or sloppy. The typical 8mm end-supported round guide rails are pretty flexible. If you replace them with larger diameter rails, or better yet, fully supported rails you will see big improvements in print quality. Those round rails are OK, but the bearings that ride on them usually have some slop. Using linear guides will eliminate the slop. Linear guides have a single rectangular rail with slots cut into two sides. They usually come with a rectangular bearing block or two that rides in the grooves. There is no play in the motion- they slide easily and smoothly along the rail, which is always intended to be fully supported. The first time you handle one you'll be amazed at the precision of the motion it produces, and then you'll think, "yeah, this should be in my printer".

Before you panic and say "they're too expensive", take a look at ebay. You can find some real bargains on linear guides if you take the time to look. I recently picked up an unused, old stock IKO LWLF 24 linear guide with a bearing block, almost 21" long, for $34 including shipping. Too long isn't a problem- they can be cut to the needed length using a cut off wheel on a grinder. As far as other dimensions go, it really isn't important. 3D printers are equivalent to no load on linear guides- they will last forever in a 3D printer, so small ones are fine.

Linear guides are very compact compared to using pairs of round guide rails. I switched from 1/2" round rails in my printer to 12 mm linear guides in the X and Y axes about a year ago. My extruder carriage is now just a piece of rectangular tubing and an L bracket with the drive belt attached at the bottom and the extruder screwed down with two screws. It can't get much simpler mechanically, yet the performance is far beyond anything else you can do. There is no play at the extruder nozzle at all.

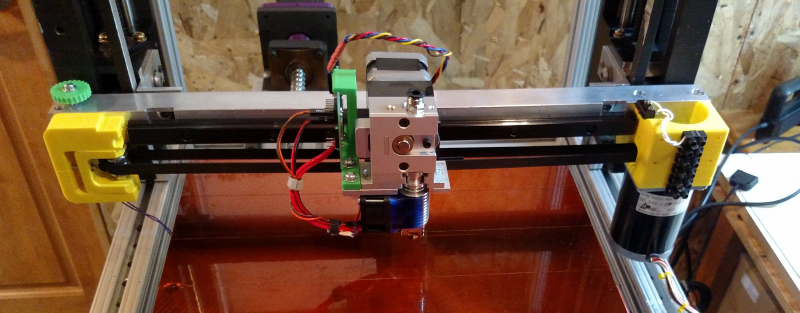

Here's the X axis as it looks now- the linear guide is screwed down to a piece of 1" square aluminum tubing:

Here's what it looked like when it had 1/2" round guide rails- the rails were held in brackets that were screwed to a piece of 1.5" square 8020:

I recommend 1/4" cast aluminum tooling plate for the print bed. It has all the characteristics needed- flat, thermally conductive, and it's easy to cut and drill. Mount it on a 3 point leveling system (not 4- it doesn't work).

If you build the machine with a rigid frame, rigid rails, and use a 1/4" bed plate, you won't need autoleveling. You'll set the bed level and won't have to touch it again. I recently tweaked the level and zero adjustments on my printer's bed for the first time in about 6 months.

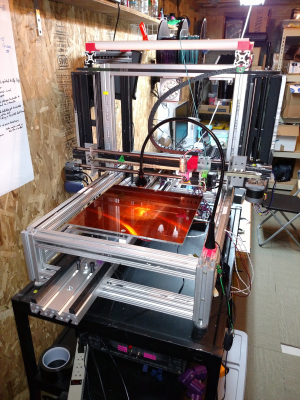

You can see the whole printer by clicking the link in my sig, below.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

One of the big problems with buying a kit is that they typically have poor frame construction. That severely limits what you can do to improve the machine.

If you decide to DIY, by all means start with a rigid frame, but also think in terms of eliminating anything else that's flexible or sloppy. The typical 8mm end-supported round guide rails are pretty flexible. If you replace them with larger diameter rails, or better yet, fully supported rails you will see big improvements in print quality. Those round rails are OK, but the bearings that ride on them usually have some slop. Using linear guides will eliminate the slop. Linear guides have a single rectangular rail with slots cut into two sides. They usually come with a rectangular bearing block or two that rides in the grooves. There is no play in the motion- they slide easily and smoothly along the rail, which is always intended to be fully supported. The first time you handle one you'll be amazed at the precision of the motion it produces, and then you'll think, "yeah, this should be in my printer".

Before you panic and say "they're too expensive", take a look at ebay. You can find some real bargains on linear guides if you take the time to look. I recently picked up an unused, old stock IKO LWLF 24 linear guide with a bearing block, almost 21" long, for $34 including shipping. Too long isn't a problem- they can be cut to the needed length using a cut off wheel on a grinder. As far as other dimensions go, it really isn't important. 3D printers are equivalent to no load on linear guides- they will last forever in a 3D printer, so small ones are fine.

Linear guides are very compact compared to using pairs of round guide rails. I switched from 1/2" round rails in my printer to 12 mm linear guides in the X and Y axes about a year ago. My extruder carriage is now just a piece of rectangular tubing and an L bracket with the drive belt attached at the bottom and the extruder screwed down with two screws. It can't get much simpler mechanically, yet the performance is far beyond anything else you can do. There is no play at the extruder nozzle at all.

Here's the X axis as it looks now- the linear guide is screwed down to a piece of 1" square aluminum tubing:

Here's what it looked like when it had 1/2" round guide rails- the rails were held in brackets that were screwed to a piece of 1.5" square 8020:

I recommend 1/4" cast aluminum tooling plate for the print bed. It has all the characteristics needed- flat, thermally conductive, and it's easy to cut and drill. Mount it on a 3 point leveling system (not 4- it doesn't work).

If you build the machine with a rigid frame, rigid rails, and use a 1/4" bed plate, you won't need autoleveling. You'll set the bed level and won't have to touch it again. I recently tweaked the level and zero adjustments on my printer's bed for the first time in about 6 months.

You can see the whole printer by clicking the link in my sig, below.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Help deciding on a build November 02, 2015 08:33AM |

Registered: 9 years ago Posts: 722 |

Hi guys,

Well, the I3V from Makerfarm already have all you need, with fiew options.

Through, if you know how to drill, you can make the bed upgrade by yourself.

The Greg's Wade is a great feeder.

Now, it's just about what are you ready to pay for ?

With the MarkerFarm's kit, anything in the kit match together,

follow the instructions, a bit of calibration, and you're ready to go !

But, it's obviously more expensive than to source parts by yourself.

IMHO, MakerFarm's I3V is mostly a good printer, with aluminium extrusions

instead of the threaded rod Y chassis, and that's a good point.

Otherhand, the 1/4" plywood is too thin to make a good frame. Yep, there's no perfect kit.

You can follow a BOM and source your own printer.

I'm a Prusa I3 owner, and I should not recommand the Prusa I3 anyways.

Because it's an old design, with known issues, and actualy, there's much interesting !

Please consider that two designs from the Reprap community you can source the parts by yourself :

- the Itopie by Skarab.

- The SmartRapCore by Serge.

Both uses wood frames, like Makerfarm's.

The Itopie frame is much stiffer than Makerfarm's, it's a classic cartesian printer and that baby prints good.

The SmartRapCore is a fast CoreXY printer, still cheap to build.

Whatever design you will choose, the Ramps 1.4 is a standard board.

Actualy, the 32 bits boards are much better and are close to be the new standard.

Consider the RampsFD, Radds, Duet, SmoothieBoard, MKS Sbase, Azteeg mini...

Check out the Reprap's Comparison of Electronics to make up your mind.

If you're not confident with your skills and/or want to get into printing fast, buy a kit.

If you're into DIY, and if you think it will be fun to spend a lot of time

building and configurating a printer you will know from A to Z,

then source the parts by yourself and enjoy.

++JM

Edited 2 time(s). Last edit at 11/02/2015 08:36AM by J-Max.

Well, the I3V from Makerfarm already have all you need, with fiew options.

Through, if you know how to drill, you can make the bed upgrade by yourself.

The Greg's Wade is a great feeder.

Now, it's just about what are you ready to pay for ?

With the MarkerFarm's kit, anything in the kit match together,

follow the instructions, a bit of calibration, and you're ready to go !

But, it's obviously more expensive than to source parts by yourself.

IMHO, MakerFarm's I3V is mostly a good printer, with aluminium extrusions

instead of the threaded rod Y chassis, and that's a good point.

Otherhand, the 1/4" plywood is too thin to make a good frame. Yep, there's no perfect kit.

You can follow a BOM and source your own printer.

I'm a Prusa I3 owner, and I should not recommand the Prusa I3 anyways.

Because it's an old design, with known issues, and actualy, there's much interesting !

Please consider that two designs from the Reprap community you can source the parts by yourself :

- the Itopie by Skarab.

- The SmartRapCore by Serge.

Both uses wood frames, like Makerfarm's.

The Itopie frame is much stiffer than Makerfarm's, it's a classic cartesian printer and that baby prints good.

The SmartRapCore is a fast CoreXY printer, still cheap to build.

Whatever design you will choose, the Ramps 1.4 is a standard board.

Actualy, the 32 bits boards are much better and are close to be the new standard.

Consider the RampsFD, Radds, Duet, SmoothieBoard, MKS Sbase, Azteeg mini...

Check out the Reprap's Comparison of Electronics to make up your mind.

If you're not confident with your skills and/or want to get into printing fast, buy a kit.

If you're into DIY, and if you think it will be fun to spend a lot of time

building and configurating a printer you will know from A to Z,

then source the parts by yourself and enjoy.

++JM

Edited 2 time(s). Last edit at 11/02/2015 08:36AM by J-Max.

|

Re: Help deciding on a build November 02, 2015 10:49AM |

Registered: 11 years ago Posts: 1,807 |

Hi the_digital_dentist

cool printer. Looks very Stable.

For faster PrintSpeed I think you can use it.

If you like to Pimp up your electronic PM me please.

We have build an Open Source Printer named BBone with 32 bit Electronic (RADDS v1.5) and 1/128 Microstepperdriver (Raps128).

Here some Links for your Inspraion :-)

[bbone.info]

[projectbuildr.de]

Here a Printsample in PET:

Mein Club: [hackerspace-ffm.de]

RADDS-Shield -> Commercial [max3dshop.org]

cool printer. Looks very Stable.

For faster PrintSpeed I think you can use it.

If you like to Pimp up your electronic PM me please.

We have build an Open Source Printer named BBone with 32 bit Electronic (RADDS v1.5) and 1/128 Microstepperdriver (Raps128).

Here some Links for your Inspraion :-)

[bbone.info]

[projectbuildr.de]

Here a Printsample in PET:

Mein Club: [hackerspace-ffm.de]

RADDS-Shield -> Commercial [max3dshop.org]

|

Re: Help deciding on a build November 02, 2015 01:07PM |

Registered: 9 years ago Posts: 517 |

Check out [openbuilds.com] for some project ideas. There are some nice builds on there and you can probably find one that meets your requirements.

Sorry, only registered users may post in this forum.