Part Fan Duct: how close to nozzle | directed or around the nozzle?

Posted by realthor

|

Part Fan Duct: how close to nozzle | directed or around the nozzle? January 28, 2016 06:14PM |

Registered: 9 years ago Posts: 1,035 |

Hello guys, I have a simple question regarding the design and proximity to the nozzle of the fan duct. I see all shapes and sizes and wonder the following:

1) how close can you put the tip of the fan duct to the nozzle so that it doesn't melt? For PLA, ABS, Nylon?

2) does it really make any difference if the air is directed towards the nozzle or the area just below the nozzle in a single orientation or if the funnel envelops the nozzle providing air from all sides?

For the first question I guess the answer would be as close as possible so that the air stream doesn't hit the nozzle itself but the part just below it. This is a very precise requirement that I don't think many of the funnels out there comply with and I have a hard time believing that it can be achieved with plastic funnels.

On the other hand, what funnel designs have worked best for you and if you have determined what made the funnel perform.

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

1) how close can you put the tip of the fan duct to the nozzle so that it doesn't melt? For PLA, ABS, Nylon?

2) does it really make any difference if the air is directed towards the nozzle or the area just below the nozzle in a single orientation or if the funnel envelops the nozzle providing air from all sides?

For the first question I guess the answer would be as close as possible so that the air stream doesn't hit the nozzle itself but the part just below it. This is a very precise requirement that I don't think many of the funnels out there comply with and I have a hard time believing that it can be achieved with plastic funnels.

On the other hand, what funnel designs have worked best for you and if you have determined what made the funnel perform.

Thanks.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Part Fan Duct: how close to nozzle | directed or around the nozzle? January 28, 2016 09:06PM |

Registered: 9 years ago Posts: 1,873 |

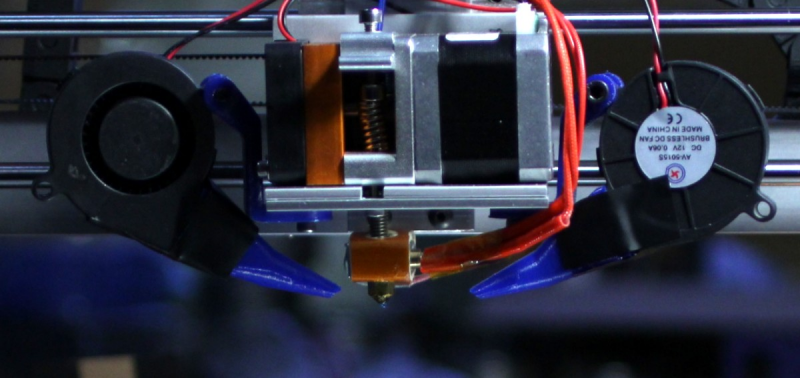

I have the duct on one side of my nozzle closer than I'd like (it's on the todo list to make a new mount). It's printed in nylon and no sign of any problems yet.

These ducts are one I found on thingiverse: [www.thingiverse.com]

It's an interesting challenge, I'd like to try designing one of my own at some point.

These ducts are one I found on thingiverse: [www.thingiverse.com]

It's an interesting challenge, I'd like to try designing one of my own at some point.

|

Re: Part Fan Duct: how close to nozzle | directed or around the nozzle? January 29, 2016 04:25AM |

Registered: 9 years ago Posts: 1,035 |

So the funnel on the left you say is too close to the nozzle. Why do you say that? I thought that proximity to the nozzle is a good thing as long as it doesn't actually blow too much air onto the nozzle itself to cool it but send the airstream just below the tip of the nozzle (which is kind of impossible to achieve I know, but that's the actual purpose of the part-fan).

On a second note, could a single small blower fan -the ones you see everywhere on thingiverse- provide enough cooling for two hotends? I've seen axial single-fan cases that cool two hotends I suppose a blower fan can be more effective?...

On a side note nice hotend you got there. Care to provide some info?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

On a second note, could a single small blower fan -the ones you see everywhere on thingiverse- provide enough cooling for two hotends? I've seen axial single-fan cases that cool two hotends I suppose a blower fan can be more effective?...

On a side note nice hotend you got there. Care to provide some info?

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Part Fan Duct: how close to nozzle | directed or around the nozzle? January 29, 2016 06:58AM |

Registered: 9 years ago Posts: 1,873 |

Just from a practical perspective, the fan on the right is easier to work with. With one on the left being so close, it's difficult to get a position where the air doesn't hit the nozzle and the tip of the duct is still clear of the print. Other than bridging, I don't think the airflow needs to be so closely targeted at the nozzle tip either, it seems to me that a fairly general cooling of the print is what's needed, so a bit more distance helps spread the air flow around a bit, at least with these ducts which have a fairly small exit. I think a better design might have a larger exit with a little more angle away from the nozzle.Quote

So the funnel on the left you say is too close to the nozzle. Why do you say that?

As far as using one fan to cover two print heads, my guess is yes. These two fans produce a huge amount of air, and at full speed can drop nozzle and bed temperatures dramatically. I rarely run them at more than 50% except for cooling everything down after the print has finished. So from a simple airflow point of view I think one fan could do the job. The difficult bit would be designing the duct to make sure that there was even coverage of the area around both nozzles, otherwise you'd get special cases where one nozzle was printing a small island and the air wasn't reaching the hot part of the print.

The hotend is just one of the Chinese MK8 knockoffs from Aliexpress - fantastic value and works great. I have a second one, so I'm going to redesign the X axis to go dual extruder

|

Re: Part Fan Duct: how close to nozzle | directed or around the nozzle? January 29, 2016 08:04AM |

Registered: 9 years ago Posts: 1,035 |

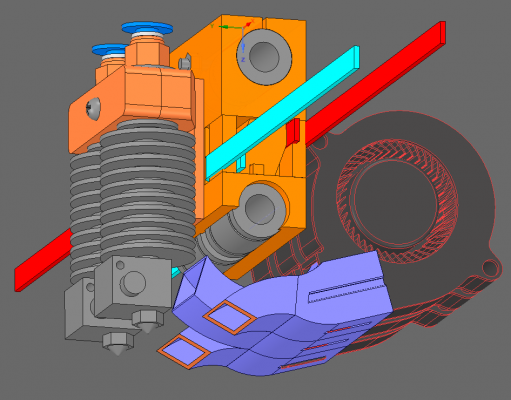

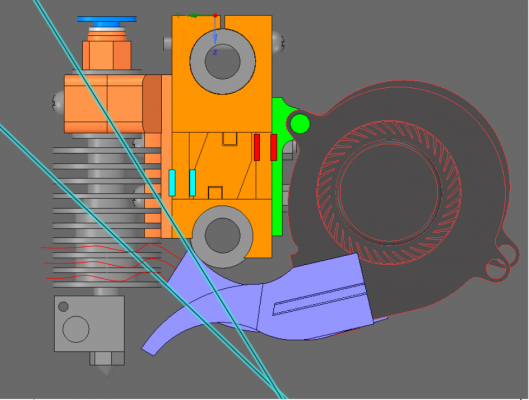

Ok I have to spill it now: my original question was generated by a triple squirrel cage blower design I have for some time on the backburner. It's nothing but an idea so any criticism is greatly appreciated. I have a whole list of my own

Now the distance between the nozzle and the funnel tip is ~9mm ... maybe too close. If this is too close I can always re-design for the second picture above. The funnels are snap-fit on the blower mouth so I can just print a few for different purposes and rotate the blowers, snap another funnel, rotate-back.

Another issue I have with this "compact" design is that the blower in the middle will have little room to suck the air. about 5mm with the current design. I don't know how to test if it can suck enough air through a 5mm gap to the next blower. Moreover, I'll have to redesign the tip so it's more trumpet-like, spreading the air better on the two hotends.

I can install an axial fan on the extruders, classical way, but this above seemed such a nice idea .

.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Now the distance between the nozzle and the funnel tip is ~9mm ... maybe too close. If this is too close I can always re-design for the second picture above. The funnels are snap-fit on the blower mouth so I can just print a few for different purposes and rotate the blowers, snap another funnel, rotate-back.

Another issue I have with this "compact" design is that the blower in the middle will have little room to suck the air. about 5mm with the current design. I don't know how to test if it can suck enough air through a 5mm gap to the next blower. Moreover, I'll have to redesign the tip so it's more trumpet-like, spreading the air better on the two hotends.

I can install an axial fan on the extruders, classical way, but this above seemed such a nice idea

.

.RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Part Fan Duct: how close to nozzle | directed or around the nozzle? January 29, 2016 08:19AM |

Registered: 9 years ago Posts: 1,873 |

Looks awesome - that should provide a whole boatload of cooling! It will be noisy when you crank all three fans, but my guess is the print fans will mostly run in the 10 to 20% region which is fine. If you use another pin to control the cold-end fan you can PWM that too if it turns out you don't need full speed.

Duct to nozzle distance looks fine in your drawings, and I would think the 5mm gap on the intake side will be fine as the total inlet area is much larger than the outlet. (won't there be two blowers that are restricted this way?).

You might want to add something to make sure that air from the middle blower doesn't bounce off the heatsinks and go back down around the print area. You want to maximise the control you have of when air hits the print, so you don't want any accidental spill.

Overall it may be a little overkill, but it's better to have too much cooling ability and back it off under software than too little. And it sure looks the business!

Edited 1 time(s). Last edit at 01/29/2016 08:20AM by JamesK.

Duct to nozzle distance looks fine in your drawings, and I would think the 5mm gap on the intake side will be fine as the total inlet area is much larger than the outlet. (won't there be two blowers that are restricted this way?).

You might want to add something to make sure that air from the middle blower doesn't bounce off the heatsinks and go back down around the print area. You want to maximise the control you have of when air hits the print, so you don't want any accidental spill.

Overall it may be a little overkill, but it's better to have too much cooling ability and back it off under software than too little. And it sure looks the business!

Edited 1 time(s). Last edit at 01/29/2016 08:20AM by JamesK.

|

Re: Part Fan Duct: how close to nozzle | directed or around the nozzle? January 29, 2016 08:56AM |

Registered: 9 years ago Posts: 1,035 |

Quote

JamesK

Duct to nozzle distance looks fine in your drawings, and I would think the 5mm gap on the intake side will be fine as the total inlet area is much larger than the outlet. (won't there be two blowers that are restricted this way?).

If all squirrel cage blowers are made the same way and there is no "mirror" option then yes, I will have two of them in that situation. I figured that there should be such blowers but if I search more carefully online I can't really find any. I hope the 5mm gap is enough in that case

...

...Quote

JamesK

You might want to add something to make sure that air from the middle blower doesn't bounce off the heatsinks and go back down around the print area. You want to maximise the control you have of when air hits the print, so you don't want any accidental spill.

Yes, that trumpet-like funnel will actually reach the hotend after the first fin|washer so that the bounced air fill float outside the area.

The air will not reach upper fins but if enough cooling is ensured at the first few fins then I guess not much heat will creep ip. If this is not the case I will have to design a deflector of some sort to spiral the air upwards instead of letting it leave the hotend too quickly.

I basically wanted it to be modular. If I am not using 2 hotends, take 1 out, swap it for a induction probe, away with one blower, etc.

I am still pondering that one hotend will have a direct extruder (no-bowden), but that has to be small

because my X rods are 8mm. Can't we do Flying Extruder with cartesian? I have to think of that.

because my X rods are 8mm. Can't we do Flying Extruder with cartesian? I have to think of that.Edited 2 time(s). Last edit at 01/29/2016 11:32AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Part Fan Duct: how close to nozzle | directed or around the nozzle? January 30, 2016 04:53AM |

Registered: 8 years ago Posts: 3,525 |

That looks like it will cool parts very well but I wonder if the hot end heatsink cooler in this design will provide enough cooling without a fan shroud to direct the air over the heatsink fins.

Flex3drive is the way to go for lightweight it's 49g, I have one but haven't used it yet as my flying extruder is so good. But I've got a smartrapcore alu on the way and will definitely give it a try.

But why not do a flying extruder, it must be possible to suspend a fairly simple 1.75mm direct drive over the build area above the print head it's just a case of getting enough elasticity so that the bowden tube remains attached during printing. It would be easy for a 100mm square sized build area but gets more problematic with a larger travel.

Edited 1 time(s). Last edit at 01/30/2016 04:58AM by DjDemonD.

Flex3drive is the way to go for lightweight it's 49g, I have one but haven't used it yet as my flying extruder is so good. But I've got a smartrapcore alu on the way and will definitely give it a try.

But why not do a flying extruder, it must be possible to suspend a fairly simple 1.75mm direct drive over the build area above the print head it's just a case of getting enough elasticity so that the bowden tube remains attached during printing. It would be easy for a 100mm square sized build area but gets more problematic with a larger travel.

Edited 1 time(s). Last edit at 01/30/2016 04:58AM by DjDemonD.

|

Re: Part Fan Duct: how close to nozzle | directed or around the nozzle? January 30, 2016 06:18AM |

Registered: 9 years ago Posts: 1,035 |

Quote

DjDemonD

That looks like it will cool parts very well but I wonder if the hot end heatsink cooler in this design will provide enough cooling without a fan shroud to direct the air over the heatsink fins.

I am thinking of a screw-like shroud that will force air upwards but am not that skilled in design. Something inspired from these helix wind turbines. I liked the appearance of this Tornado Extruder. I thought that it's just for looks purposes and all that extra plastic is unnecessary but in my case some plastic encasing the two hotends could be necessary. If I only had the skills to make something nice

Quote

DjDemonD

But why not do a flying extruder, it must be possible to suspend a fairly simple 1.75mm direct drive over the build area above the print head it's just a case of getting enough elasticity so that the bowden tube remains attached during printing. It would be easy for a 100mm square sized build area but gets more problematic with a larger travel.

I'll have to experiment with that. I have some fancy ideas... have to think a bit deeper about it. It's not priority right now i have to build this current bowden (so far) design.

Edited 1 time(s). Last edit at 01/30/2016 06:27AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

|

Re: Part Fan Duct: how close to nozzle | directed or around the nozzle? January 30, 2016 10:04AM |

Registered: 9 years ago Posts: 1,035 |

I think it's more practical to have an axial fan in the front for the hotends afterall. Unless I get a better idea.

Edited 3 time(s). Last edit at 01/31/2016 12:25AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Edited 3 time(s). Last edit at 01/31/2016 12:25AM by realthor.

RepRap Lander concept on Concept Forge

RepRap Lander concept on RepRap Forums

My Things, mostly experimental stuff

Sorry, only registered users may post in this forum.